Electric strength inspection device for oil paper compound insulation oil during flowing

A technology of composite insulation and electric strength, applied in the direction of testing dielectric strength, material breakdown voltage, etc., can solve the problems of processing error, installation difficulty, flashover, etc., and achieve the effect of improving flashover voltage and preventing flashover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

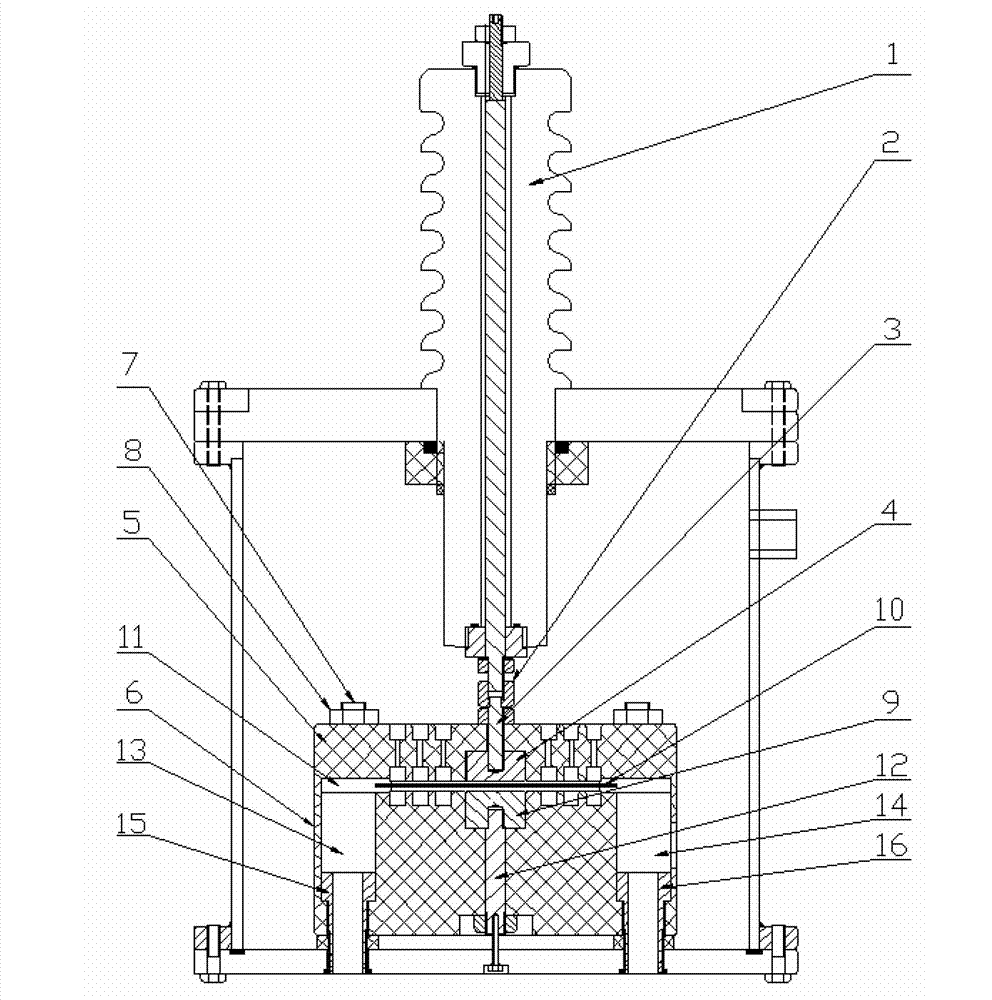

[0014] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the oil-paper composite insulating oil flowing down electric strength testing device described in this embodiment, it includes high voltage bushing 1, high voltage bushing lower connector 2, upper electrode connector 3, upper electrode 4, upper electrode insulator 5. Lower electrode insulation 6, insulating screw 7, insulating nut 8, lower electrode 9, insulating cardboard 10, oil channel 11, grounding bolt 12, oil inlet 13, oil outlet 14, oil inlet connector 15 and Oil outlet connector 16,

[0015] High-voltage bushing lower connector 2, upper electrode connector 3, upper electrode 4, upper electrode insulator 5, lower electrode insulator 6, insulating screw 7, insulating nut 8, lower electrode 9, insulating cardboard 10, oil passage 11 and the ground bolt 12 are set in the high-pressure test box,

[0016] The upper electrode 4 is arranged directly above the lower electrode...

specific Embodiment approach 2

[0022] Embodiment 2: In this embodiment, Embodiment 1 is further described. The connection between the upper electrode connector 3 and the lower connector 2 of the high-voltage bushing is connected by a dynamic fit. Prevent connection difficulties due to the accumulation of machining errors, thereby introducing high potential into the upper electrode.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment further describes Embodiment 1. The inner surfaces of the upper electrode insulator 5 and the lower electrode insulator 6 are milled with multiple grooves. To increase the flashover voltage and prevent flashover from happening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com