Alcohol-based fuel clean gasification combustion cooker

An alcohol-based fuel and cooker technology, applied in the cooker field, can solve the problems of a large amount of harmful gas, waste of energy, troublesome operation, etc., and achieve the effects of reducing harmful gas emissions, improving combustion efficiency, and reducing latent heat of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

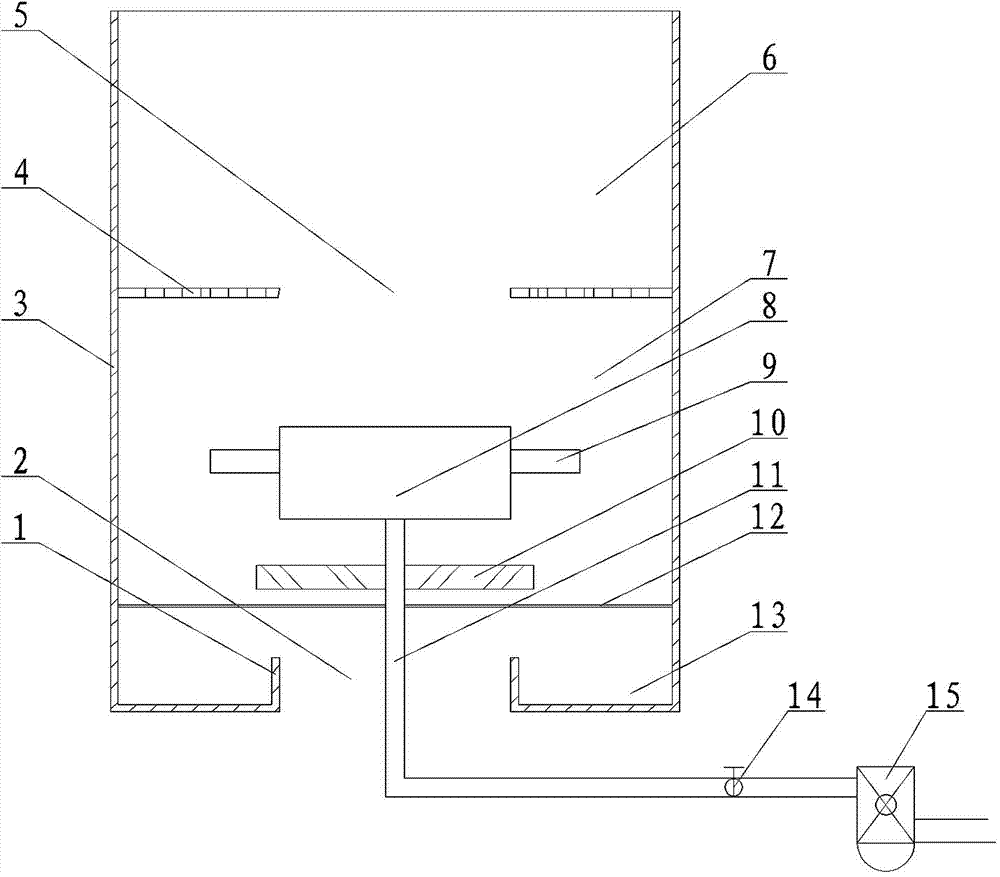

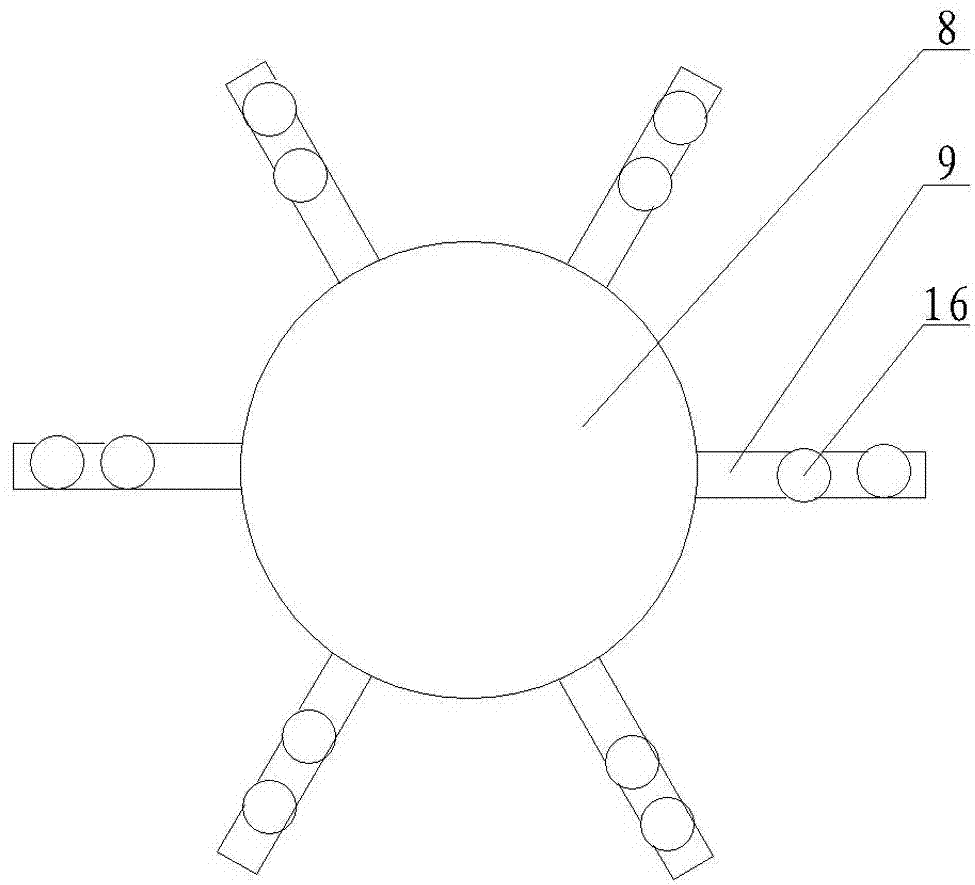

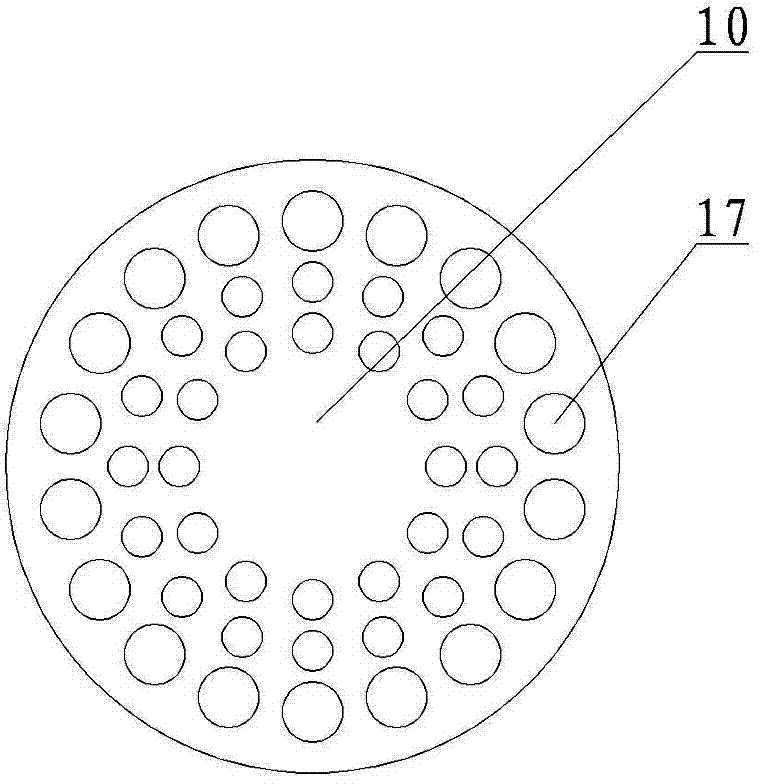

[0043] The structure of alcohol-based fuel clean gasification combustion cooker is as follows: figure 1 As shown, it is composed of a stove body 3, a gasifier 8, a secondary gasifier 4, a rotary air distributor 10 and an oil delivery pipe 11. The cooker body 3 is a cylinder-shaped cavity, and an annular cofferdam 1 is arranged at the bottom of the cooker body 3. The central opening of the cofferdam 1 is used as an air inlet 2, and an annular pre-combustion chamber 13 is formed on the periphery. The cavity above the pre-combustion chamber 13 is separated by the secondary gasifier 4 into two parts, the upper gasification combustion chamber 6 and the mixing combustion chamber 7 .

[0044] The oil delivery pipe 11 is a hard stainless steel pipe, which passes into the mixing combustion chamber 7 of the stove body 3 from the air inlet 2, and is fixed on the stove body 3 by three radial tension ribs 12, and a needle is arranged on the oil delivery pipe 11 outside the stove body 3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com