Multifunctional combined type gasbag device

A combined, multi-functional technology that can be used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc. Reduce, wide application, ensure tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

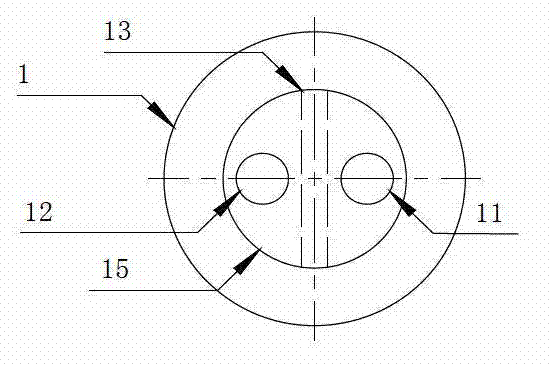

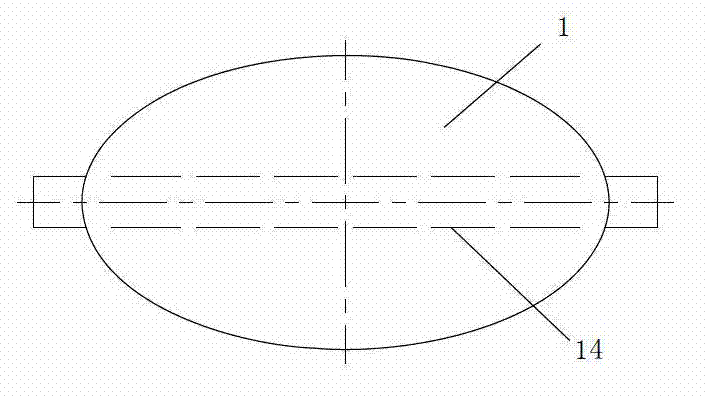

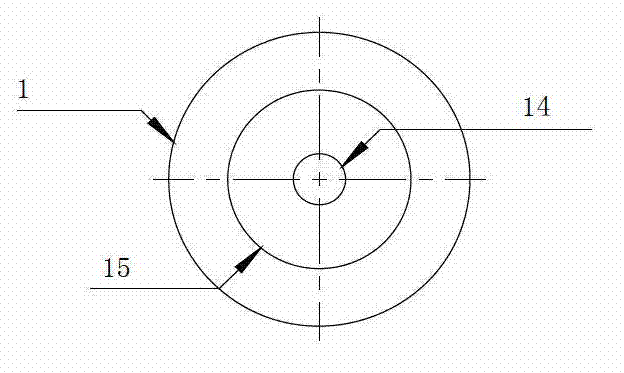

[0027] see Figure 1~5 , the embodiment of the present invention is provided with an airbag device, an airbag inflation and deflation and pressure regulating device, and a gas flow control device;

[0028] Described airbag device is provided with airbag 1, and one end of airbag 1 is provided with airbag inflation interface 11, air supply interface 12, pull ring interface 13 and metal ring 15, and airbag 1 is provided with vent pipe 14, and described vent pipe 14 runs through The entire airbag 1 is connected with the air supply interface 12 and the ventilation pipe 14 .

[0029] The air bag inflation and pressure regulating device is provided with a first argon gas cylinder 21, a first leather tube 22, a pressure regulating valve 23, an air bag pressure display gauge 24, a first gas cylinder pressure display gauge 25, a first gas cylinder three throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com