Mandatory continuous feeder for bulk material of mixed grease and glue

A technology of forced feeding and fat mixing, applied in explosives processing equipment, offensive equipment, explosives, etc., can solve problems such as uneven feeding, product quality, and safety hazards, and achieve uniform feeding, improve quality stability, and uniform feeding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

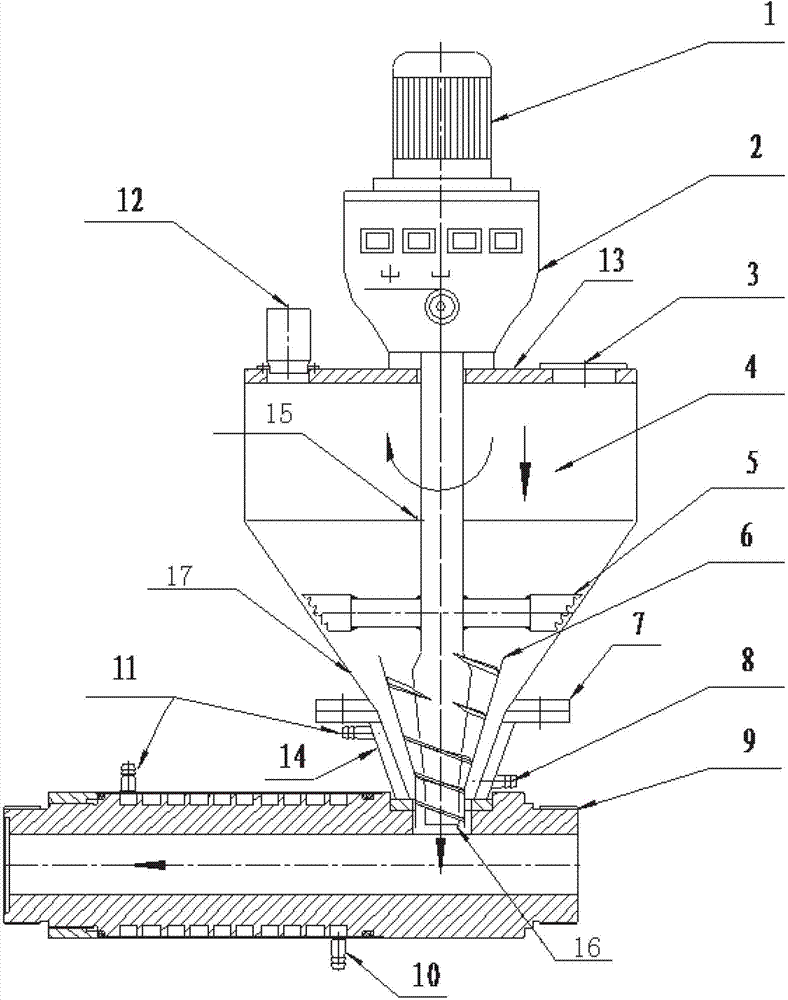

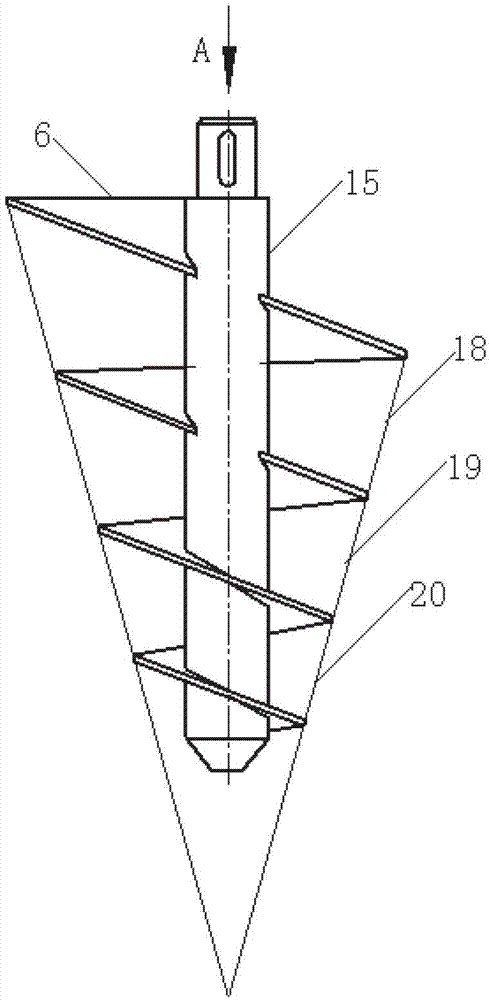

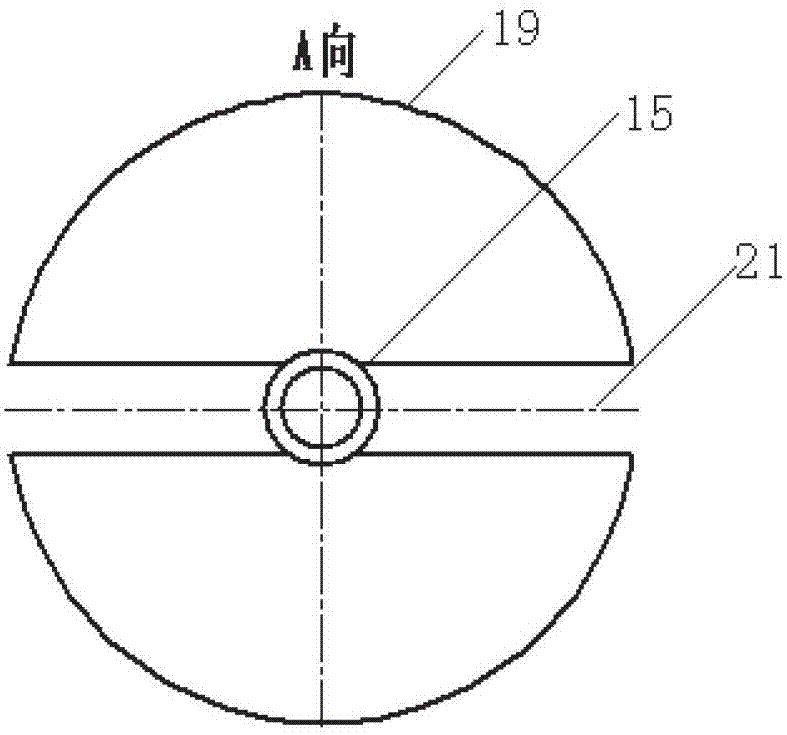

[0014] refer to figure 1 . The continuous forced feeding machine for mixed fat gelatinous materials described in the following examples mainly includes the feeding container 4 radially connected to the screw press molding machine, the conical hopper, the end cover 13 of the feeding container, and the speed reducer driven by the motor 1. 2. The feeding screw shaft 15 connected to the rotating shaft of the reducer 2, the vertical solid-linked anti-bridging mixing blade 5, that is, the special feeding screw and the outer layer insulation system, the motor 1 can be a frequency conversion motor, and is located at the top of the feeding container 4, The connection is fastened by bolts. Speed reducer 2 is powered by motor. The frequency conversion motor can be adjusted to a suitable feeder speed through frequency modulation according to the process requirements. The feeding port 3 located on the end cap 13 of the feeding container is provided with a movable flip cover for releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com