Ceramsite concrete slab

A technology of ceramsite concrete and concrete slabs, which is applied in the field of building materials, can solve the problems of insufficient strength, achieve good thermal insulation effects, good sound insulation effects, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

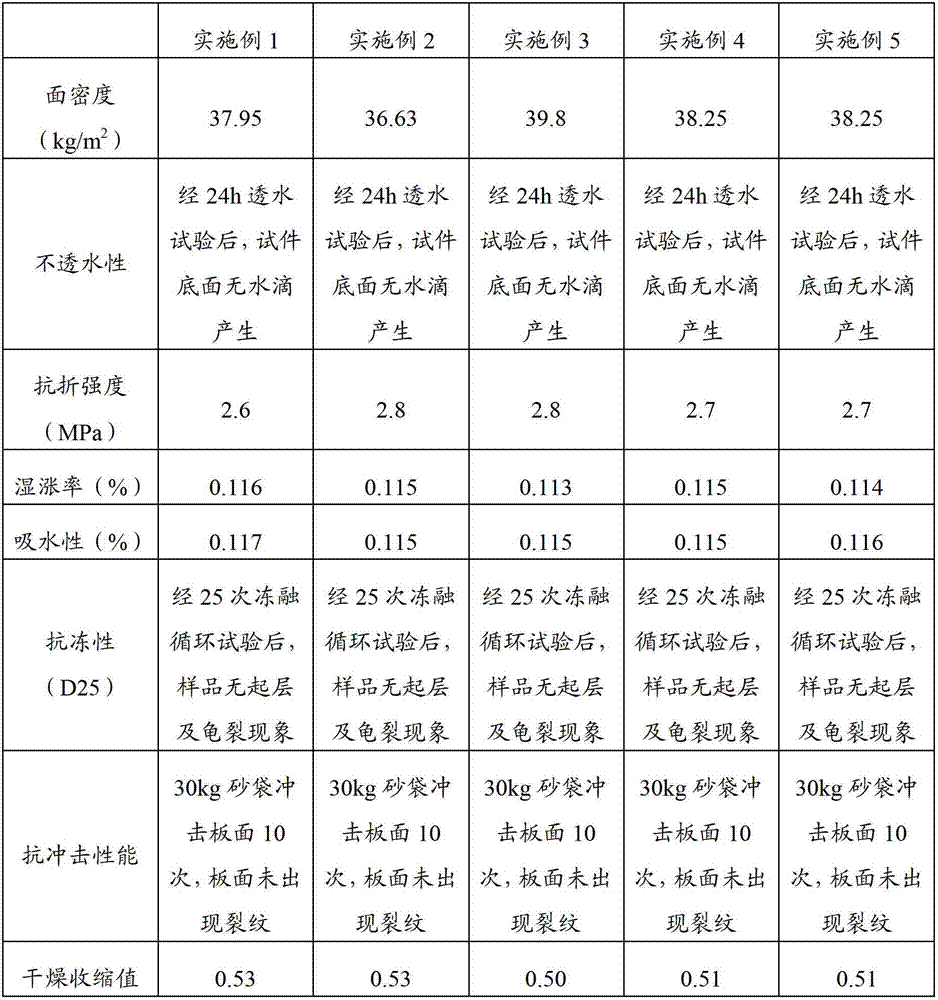

Examples

Embodiment 1

[0023] The composition of the ceramsite concrete slab is as follows: sulfoaluminate 425# cement 380kg, stone powder 850kg, ceramsite 173kg, water 115kg and two layers of barbed wire. Among them, the diameter of ceramsite is 5~20mm. Stir the sulfoaluminate 425# cement, stone powder, ceramsite and water evenly to obtain a mixture, and put a part of the evenly stirred mixture into the mold first. Then place a layer of barbed wire in the mold. Then, after putting the evenly stirred mixture into the mold, lay a layer of barbed wire, and enter the vibrating process. The size of the barbed wire is 795mm×795mm. The barbed wire has a diameter of 0.7mm and a grid size of 15mm×15mm. The galvanized wire mesh mainly plays the role of enhancing the elasticity of the ceramsite concrete slab.

[0024] The size of the ceramsite concrete slab prepared after form removal and curing is 800mm×800mm. The thickness of the ceramsite concrete slab is only 25mm, which is very convenient for transp...

Embodiment 2

[0027] The composition of the ceramsite concrete slab is as follows: sulfoaluminate 425# cement 385kg, mineral sand 790kg, ceramsite 175kg, water 115kg and two layers of barbed wire. Among them, the diameter of ceramsite is 5~10mm. Mix sulfoaluminate 425# cement, ore sand, ceramsite and water evenly to obtain a mixture, and put a part of the evenly stirred mixture into the mold first. Then place a layer of barbed wire in the mold. Then, after putting the evenly stirred mixture into the mold, lay a layer of barbed wire, and enter the vibrating process. The size of the wire mesh is 880mm×580mm. The barbed wire has a diameter of 0.72mm and a grid size of 19mm×19mm. The galvanized wire mesh mainly plays the role of enhancing the elasticity of the ceramsite concrete slab.

[0028] The size of the ceramsite concrete slab prepared after form removal and curing is 900mm×600mm. The thickness of the ceramsite concrete slab is only 25mm, which is very convenient for transportation a...

Embodiment 3

[0031] The composition of the ceramsite concrete slab is as follows: ordinary silicate 425# cement 396kg, fly ash 900kg, ceramsite 179kg, water 117kg and two layers of steel wire mesh. Among them, the diameter of ceramsite is 5~15mm. Mix ordinary silicate 425# cement, fly ash, ceramsite and water to obtain a mixture, and put a part of the mixture in the mold first. Then place a layer of steel mesh in the mold. Then, after putting the evenly stirred mixture into the mould, lay a layer of steel wire mesh and enter the vibrating process. The size of the wire mesh is 880mm×880mm. The steel wire mesh has a diameter of 0.83mm and a grid size of 23mm×23mm. The galvanized steel wire mesh mainly plays the role of enhancing the elasticity of the ceramsite concrete slab.

[0032] The size of the ceramsite concrete slab prepared after form removal and curing is 900mm×900mm. The thickness of the ceramsite concrete slab is only 25mm, which is very convenient for transportation and inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com