Chamfering machine capable of processing non-standard silicon wafer

A technology of chamfering machine and silicon wafer, applied in the field of chamfering machine, can solve the problem of not being able to process non-standard silicon wafers, etc., and achieve the effect of improving production and processing capacity and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

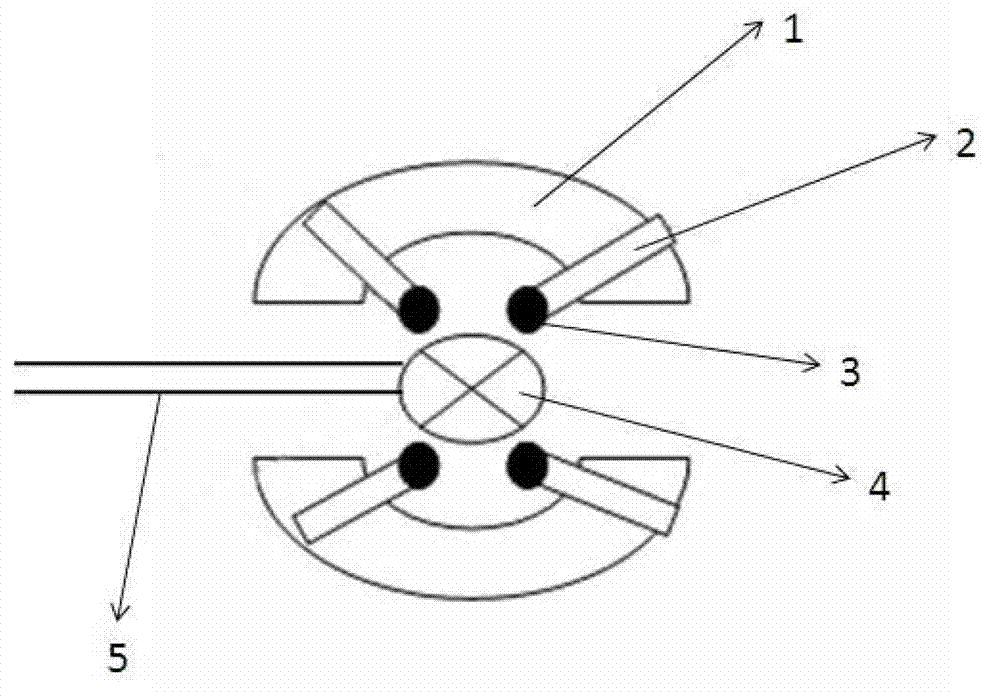

[0016] Such as figure 1 As shown, the present invention includes a regularization system, and the regularization system includes a sheet-feeding arm 5, and one end of the sheet-feeding arm 5 is provided with a circular suction piece 4, and the diameter of the suction piece 4 is 35mm; the suction piece 4 is also equipped with Two arch-shaped regular splints 1, each of the two ends of the regular splint 1 is provided with a bar-shaped positioning block 2, and one end of the positioning block 2 is fixed on the described regular splint 1 by a shaft, The angle of the positioning block 2 can be adjusted according to actual processing needs, and the other end of the positioning block 2 is provided with a positioning wheel 3 .

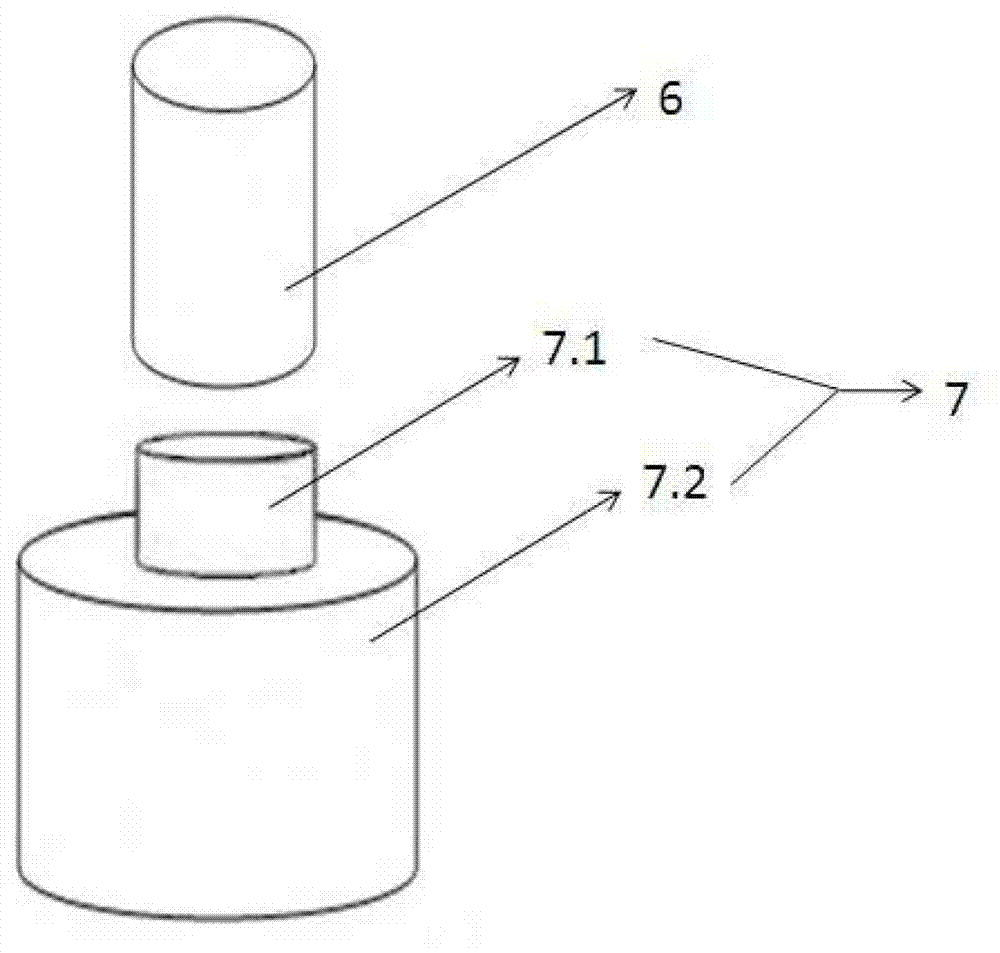

[0017] The invention also includes a processing system comprising a workbench such as figure 2 As shown, the workbench is provided with an upper clip 6 and a lower clip 7 for clamping the workpiece, the upper clip 6 is cylindrical, with a diameter of 35 mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com