Adjustment detecting method of double-optical wedge initial phase

A technology of initial phase and detection method, which is applied in the field of optics, can solve problems such as complex instrument structure and long customization cycle, and achieve the effect of simple adjustment and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Such as figure 2 As shown, 1 is the theodolite, 2 is the collimator.

[0027] 1. Adjust the verticality of the double optical wedge

[0028] 1) Place the theodolite 1 and the collimator 2 on the same horizontal platform for adjustment, so that the height of the optical path of theodolite 1 is the same as that of the center of the bracket where the optical wedge is installed (that is, the center of the double optical wedge). Adjust theodolite and collimator so that they can see each other's image in their own eyepieces, and adjust until the two images coincide.

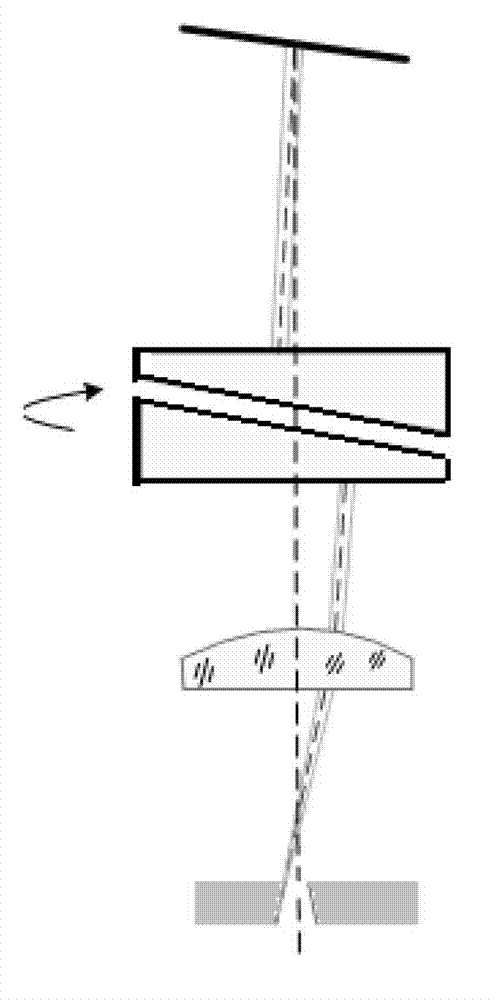

[0029] 2) Install the first optical wedge 3 on the bracket, and put it between theodolite 1 and collimator 2, as image 3 , the image reflected by the first wedge 3 in theodolite 1. Adjust the first wedge 3 so that the reticle of the image coincides with the reticle of theodolite 1; rotate the first wedge 3 to 180° to observe changes in the image, and adjust the first wedge 3 to make the image The reticle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com