Semiconductor laser processing machine with light-feedback-proof device

A laser processing machine and feedback device technology, applied in semiconductor laser devices, laser devices, laser welding equipment, etc., can solve problems such as damage, laser output power decline, and life shortening, to reduce damage, improve optical power density, prevent The effect of life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

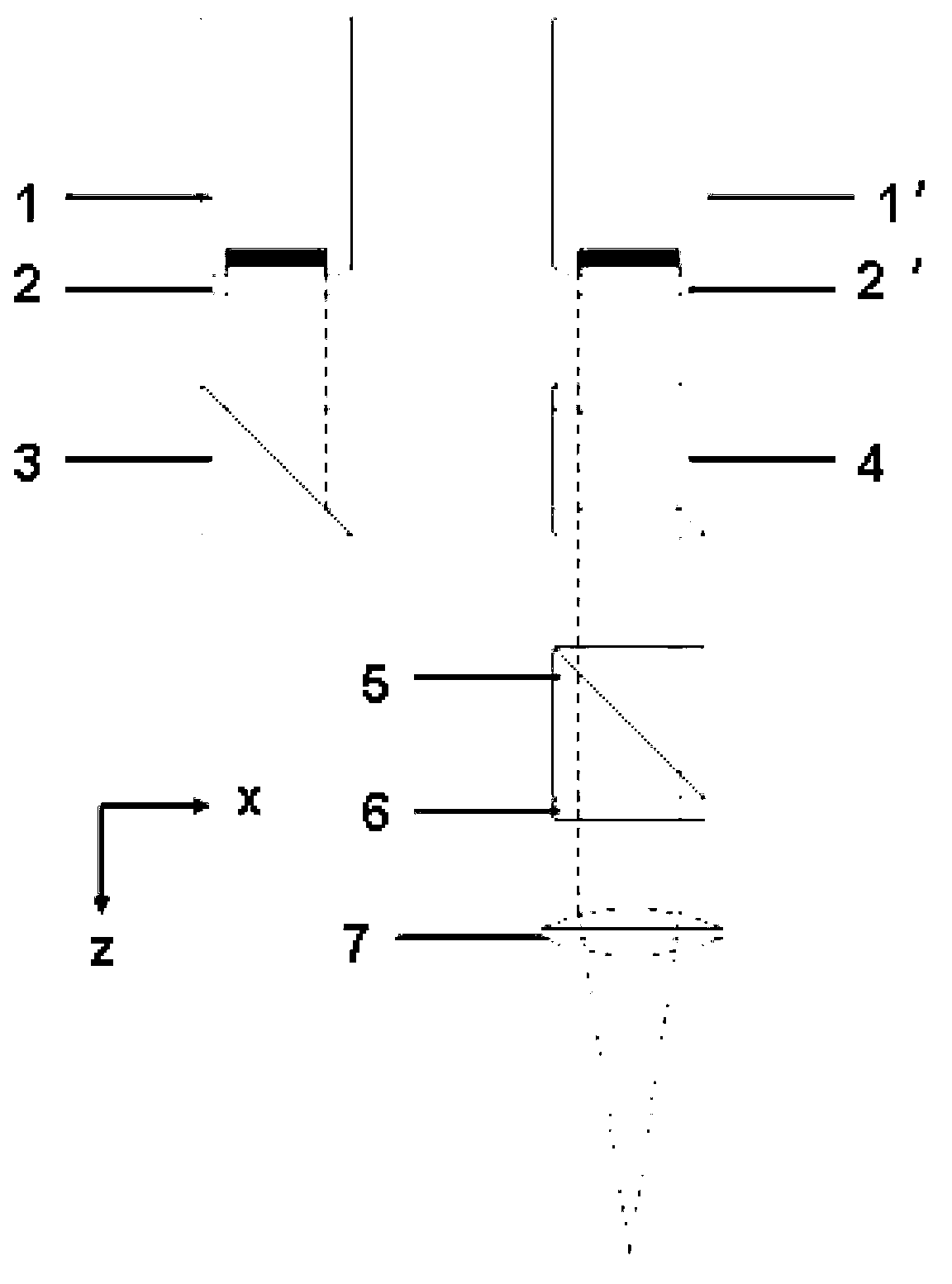

[0023] The inventive idea of the present invention is: a semiconductor laser processing machine with an anti-optical feedback device, including two semiconductor laser stacks with different wavelengths and the same polarization state arranged side by side in the same direction, and the two semiconductor laser stacks are respectively The emission wavelength is λ 1 and lambda 2 P or S polarization state laser beams; one of the semiconductor laser stacks is provided with a reflective prism set at 45° with the optical path; A wavelength beam combining prism and a polarization beam splitting prism, as well as a quarter-wave plate and a focusing mirror arranged perpendicular to the optical path; the light emitted by one of the semiconductor laser arrays is rotated by 90° after passing through the reflecting prism; the other The light emitted by the semiconductor laser stack is directly incident on the wavelength beam combining prism, and the two laser beams are combined by the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com