Miniature combined head-feed rice combine

A combined harvester and combined technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., to achieve the effects of low failure rate, increased threshing area, and improved rice threshing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

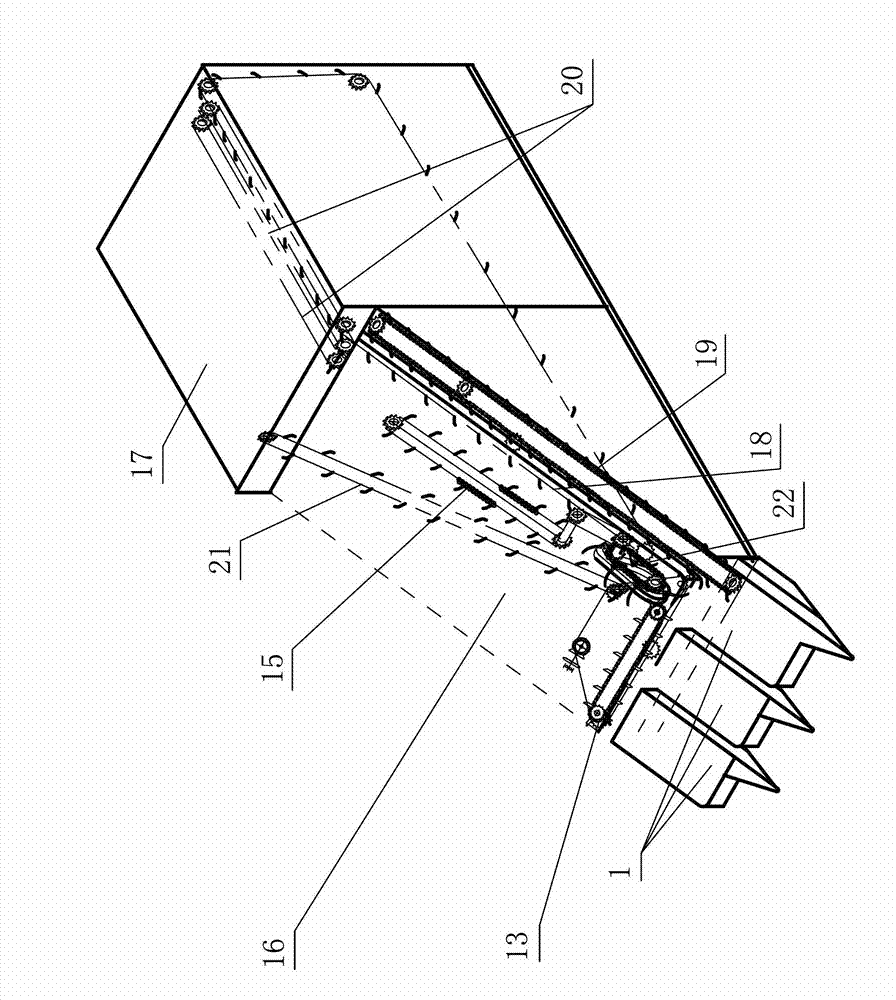

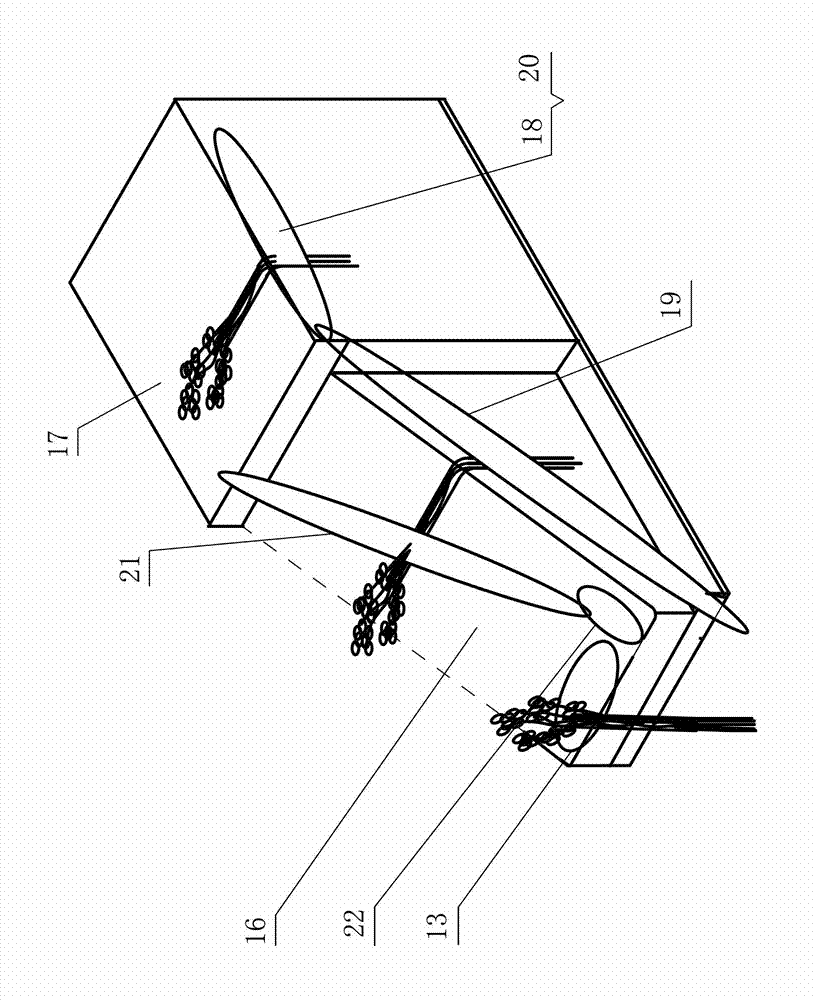

[0031] The miniature combined semi-feeding rice combine harvester of the present invention is mainly composed of a harvesting system installed on a frame, a clamping and conveying system, a power walking system and a threshing storage system.

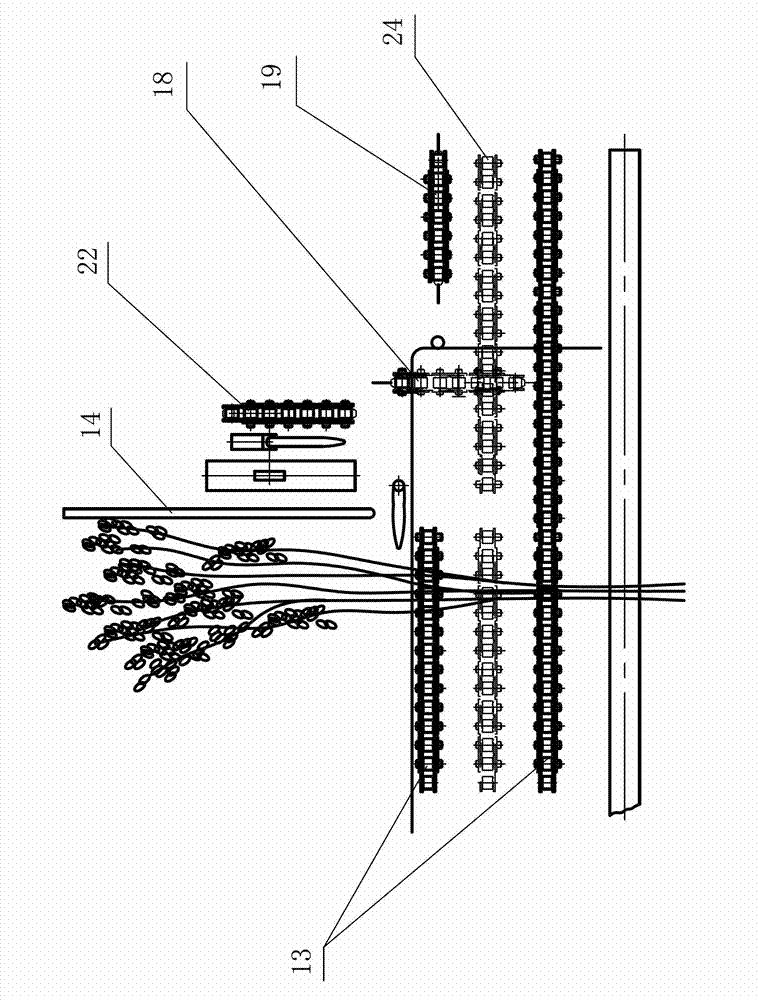

[0032] The harvesting system is composed of headers 23 of three headers 1 (obliquely forward and downward) side by side. From right to left, they are No. 1 header 1, No. 2 header 1 and No. 3 header 1. The cutting frame 23 is connected to the frame crossbeam 12 through the hanging fixed frame 11; the front end of the right side of each cutting frame 1 is provided with a grain divider 10 protruding forward, and each cutting frame 1 is provided with a reel hook tooth assembly and a transmission chain 2 and rails 3, such as Figure 5 shown.

[0033] The transmission chain 2 is arranged along the front edge, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com