An integrated threshing and separation device of drum and concave plate sieve

A technology of threshing separation and concave screen, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of blockage of threshing separation device, reduced performance of threshing separation, high production cost, etc., to increase the threshing area, reduce The effect of reducing size and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

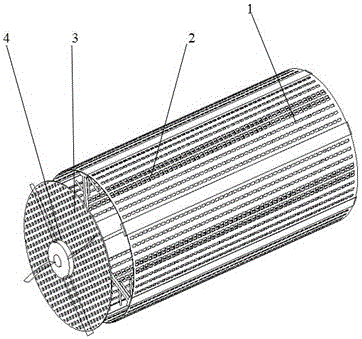

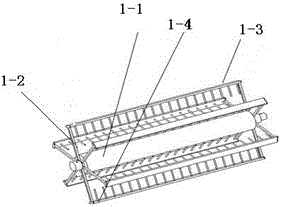

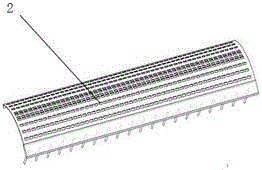

[0020] A drum and concave screen integrated threshing separation device, such as figure 1 As shown, it includes a threshing drum body 1, a sub-concave screen 2, a partition plate 3 and an impeller 4, such as figure 2 and Figure 4 As shown, the threshing cylinder body 1 is composed of a toothed plate 1-3, a connecting bracket 1-2 and a transmission shaft 1-1, and the toothed plate 1-3 is connected to the transmission shaft 1-1 through the connecting bracket 1-2 , preferably, bolts are used between the tooth plate 1-3 and the drive shaft 1-1, and bolts are used between the tooth plate 1-3 and the connecting bracket 1-2, which facilitates the disassembly of the device and the tooth plate replacement. The number of the tooth plates 1-3 is preferably 4-8, which can be changed according to actual needs. The tooth plates 1-3 are arranged in a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com