Conical friction ring gear

A technology of transmission device and friction ring, which is applied in the direction of friction transmission device, transmission device, belt/chain/gear, etc., can solve problems such as complex motion process, and achieve the effect of improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

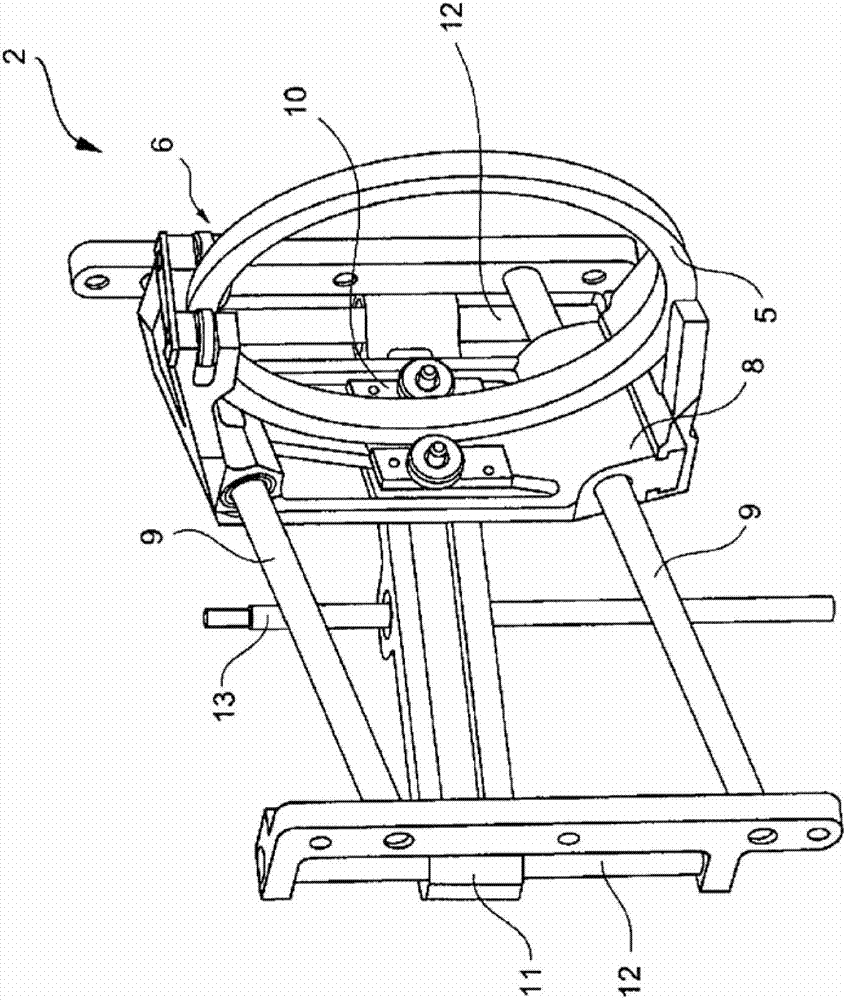

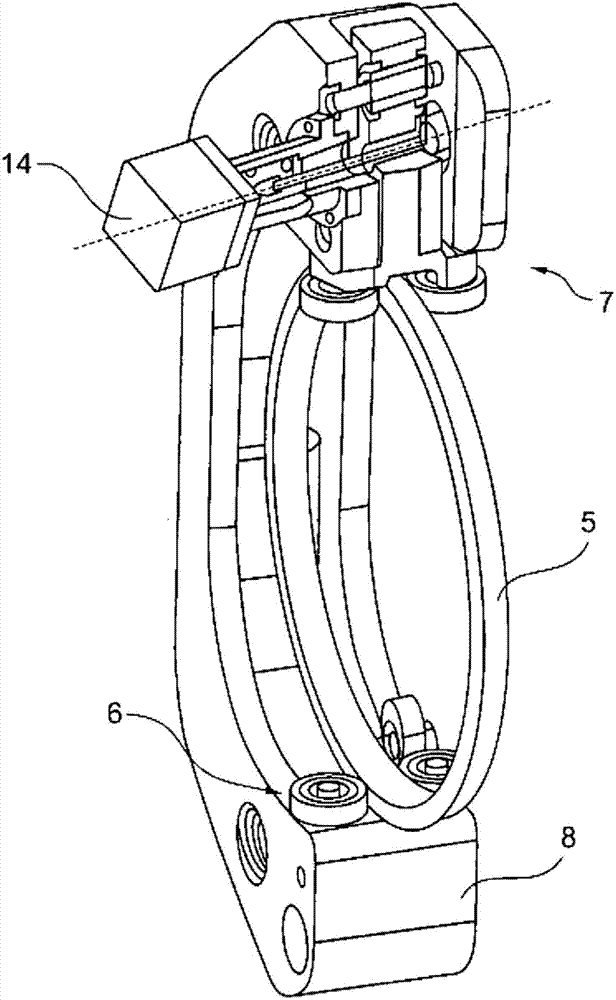

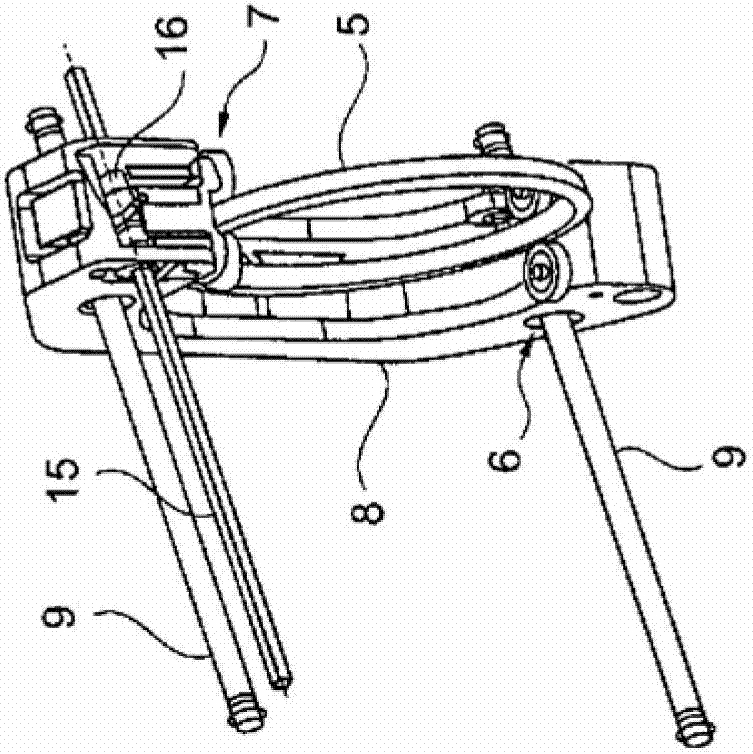

[0076] In the first embodiment, as especially in figure 1 As shown in the conical friction ring transmission 1 ( figure 1 Not shown in, in the drawings, the parts that play a similar role in different embodiments are indicated by the same reference numerals) The adjustment mechanism 2 has a friction ring guide mechanism 6, which guides the friction ring 5 for determining the friction ring position, the friction ring 5 interacts with the friction cone 3 of the conical friction ring transmission 1 in a known manner. For this purpose, the adjusting mechanism 2 has an adjusting bridge 8 , which carries the friction ring guide 6 and which is displaceable in the adjusting mechanism 2 approximately on the friction cone 3 by means of two axial guides or two adjusting bridge guides 9 . The gap between them is guided in the direction of the axis of rotation (not shown) in a known manner.

[0077] In order to adjust the transmission ratio of the conical friction ring transmission via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com