Elevator rope

A rope and elevator technology, which is applied in the direction of textile cables, textiles and papermaking, elevators, etc., can solve the problem that the coating thickness cannot be confirmed by visual inspection, such as broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

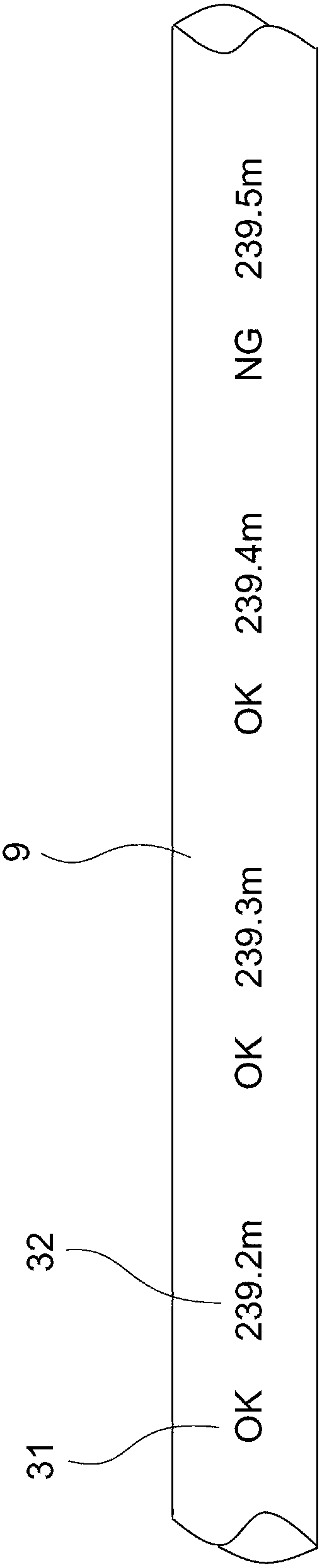

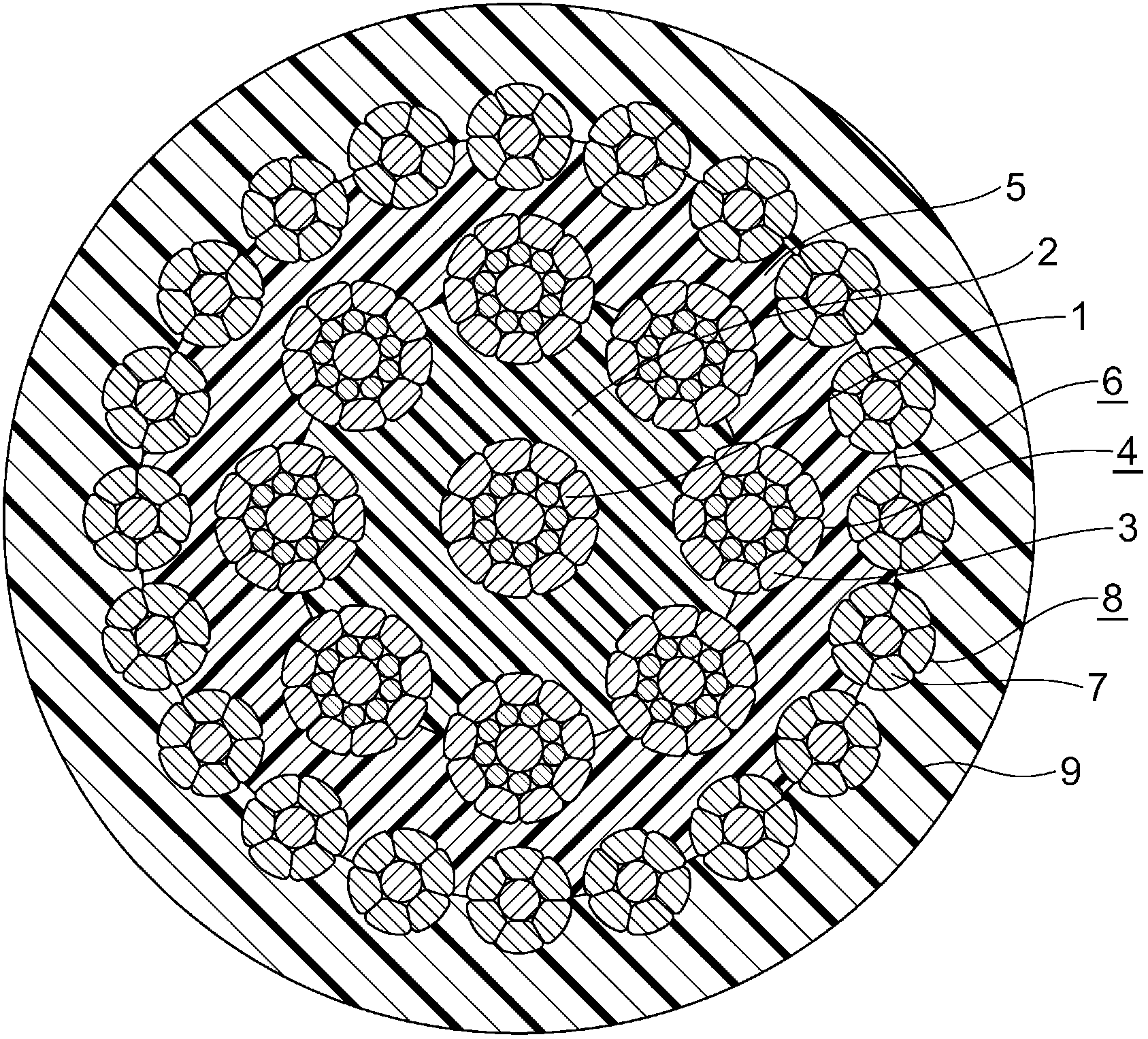

[0020] figure 1 To show a side view of the elevator rope according to Embodiment 1 of the present invention, figure 2 for figure 1 Cutaway view of an elevator with ropes. In the figure, a steel core rope 1 is arranged at the center of the elevator rope. A core rope covering body 2 made of resin is provided on the outer periphery of the core rope 1 . A plurality of (here, eight) steel core rope sub-ropes 3 are twisted on the outer periphery of the core-rope covering body 2 .

[0021] A core rope covering body 5 made of resin is provided on the outer periphery of the core rope covering body 2 and the core rope strand assembly 4 composed of eight core rope strands 3 . The core rope 6 is composed of a core rope 1 , a core rope covering body 2 , a core rope sub-rope 3 and a core rope covering body 5 .

[0022] A plurality of (here, 20) steel outer layer strands 7 are twisted around the outer periphery of the core rope covering body 5 . The rope body 8 is composed of a core r...

Embodiment approach 2

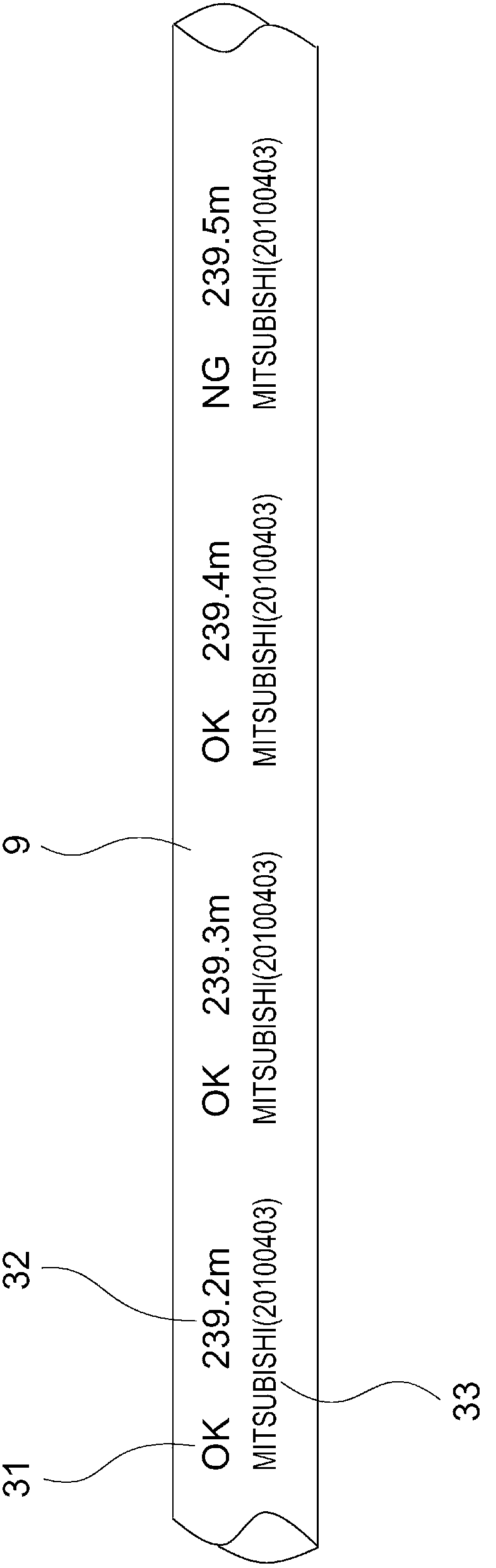

[0050] then, image 3 It is a side view showing the elevator rope according to Embodiment 2 of the present invention. In the drawing, on the surface of the outer layer covering body 9 , in addition to the inspection result information 31 and the position information 32 , the manufacturing information 33 is also recorded. As the manufacturing information 33 , a manufacturer's name, a lot number, a manufacturing date and time, and the like are listed.

[0051] In addition, the manufacturing information 33 is printed at the same pitch as the inspection result information 31 and the position information 32 in the rope length direction. In addition, the manufacturing information 33 is printed at a different position from the inspection result information 31 and the position information 32 in the circumferential direction of the outer layer covering body 9 . The other structures are the same as those in Embodiment 1.

[0052] In such an elevator rope, since the manufacturing info...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com