Low-voltage power cable for nuclear power station

A low-voltage power and nuclear power plant technology, used in power cables with shielding/conducting layers, insulated cables, cables, etc., it can solve the problems of general shielding effect, inability to cope with high-temperature accident environments, etc., and achieve good immersion performance and insulation. , the effect of twisting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

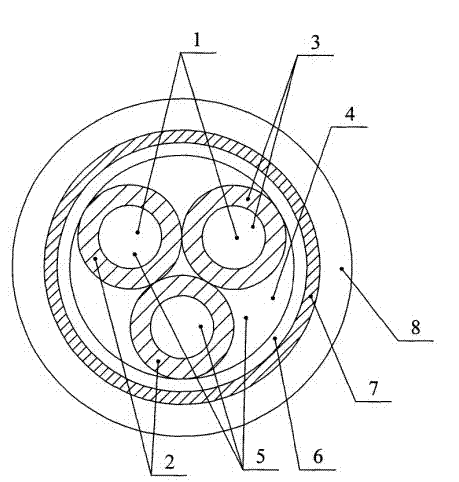

[0026] like figure 1 As shown, a low-voltage power cable for a nuclear power plant includes a conductor 1 . The number of conductors 1 is 2 or more, preferably 2-6. To illustrate the problem, 3 conductors are used as an example here. Each conductor 1 is extruded with an insulating layer 2, the insulating layer 2 and the conductor 1 form a core wire 3, three core wires 3 and filler 4 are stranded to form a cable core 5, and the cable core 5 is successively provided with a wrapping layer 6, a shielding layer 7 and a The sheath 8 and the shielding layer 7 are a copper-plastic composite tape, a braided layer of copper wire or a combination of the two. The cable core 5 is wrapped around the cladding layer 6 , and the shielding layer 7 is wrapped around the sheath 8 .

[0027] Among them: conductor 1 is preferably stranded tinned copper wire conductor; insulation layer 2 is preferably steam-crosslinked low-smoke, halogen-free, flame-retardant ethylene-propylene rubber insulation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com