Ball valve with double radial stem bearings

A radial bearing, double radial technology, applied in the direction of shaft seal, valve detail, valve device, etc., can solve the lack of packing gland radial positioning structure, increase the opening and closing torque, packing gland radial offset, etc. Problems, to achieve the effect of small friction resistance, prevent radial offset, and prevent medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

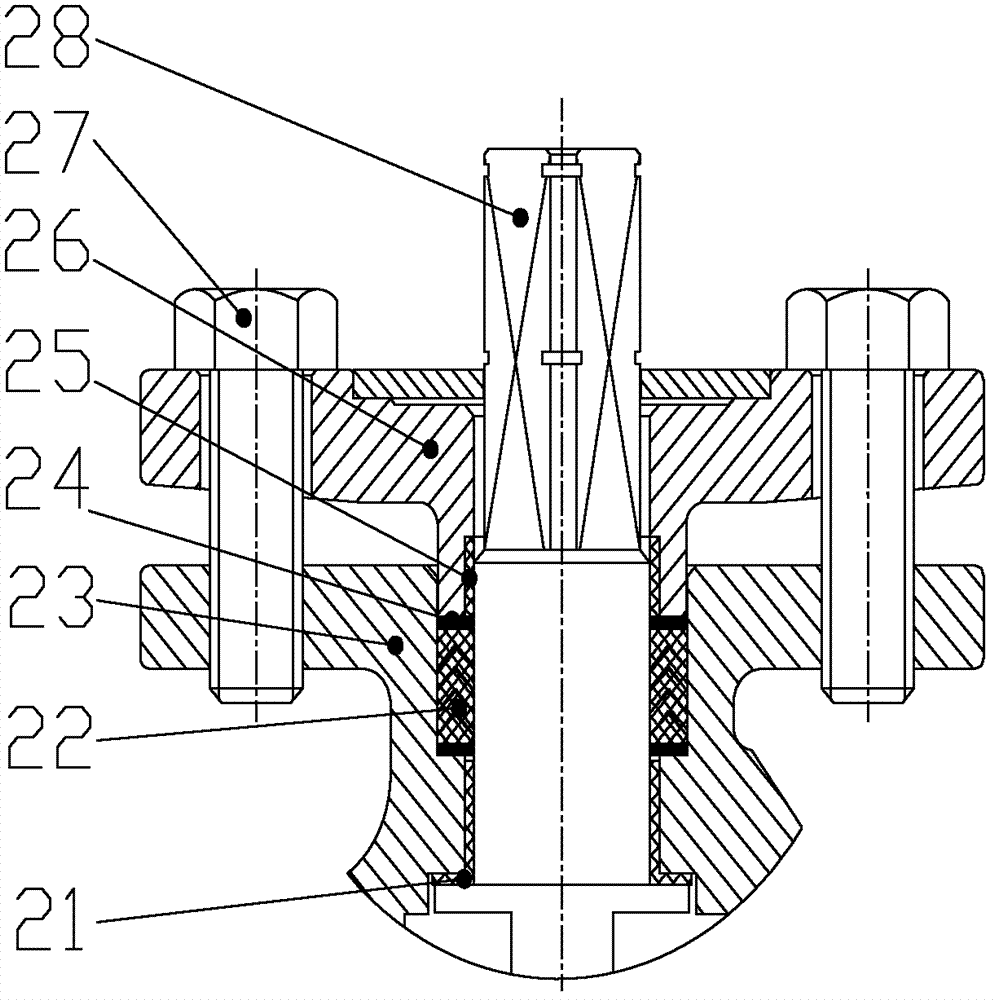

[0023] Such as figure 2 As shown, a ball valve with dual radial bearings on the valve stem, the ball valve includes a valve body 23, a packing gland 26, a valve stem 28, a packing 22, a first valve stem radial bearing 25, and a second valve stem radial bearing 21 And packing gasket 24. The packing gland 26 includes a cover plate and a grill. The cover plate and the grill are integrally arranged. There is a packing culvert on the valve body, and a groove with an inner diameter smaller than the inner diameter of the packing culvert is opened at the bottom of the packing culvert. Glam is inserted into the packing culvert, and the cover plate is connected with the valve body 23 through fasteners 27 . The lower part of the valve stem 28 is connected with the valve body 23, and the upper part of the valve stem 28 passes through the groove, the packing culvert, and the gutter in turn, and then passes through the packing gland 26, and the valve stem 28, the packing culvert, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com