A high-efficiency and energy-saving mine multi-stage machine station ventilation monitoring technology system

A high-efficiency, energy-saving, technical system technology, applied in the field of ventilation in underground mines, can solve the problems of difficult management of multi-machine stations and multi-fans, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

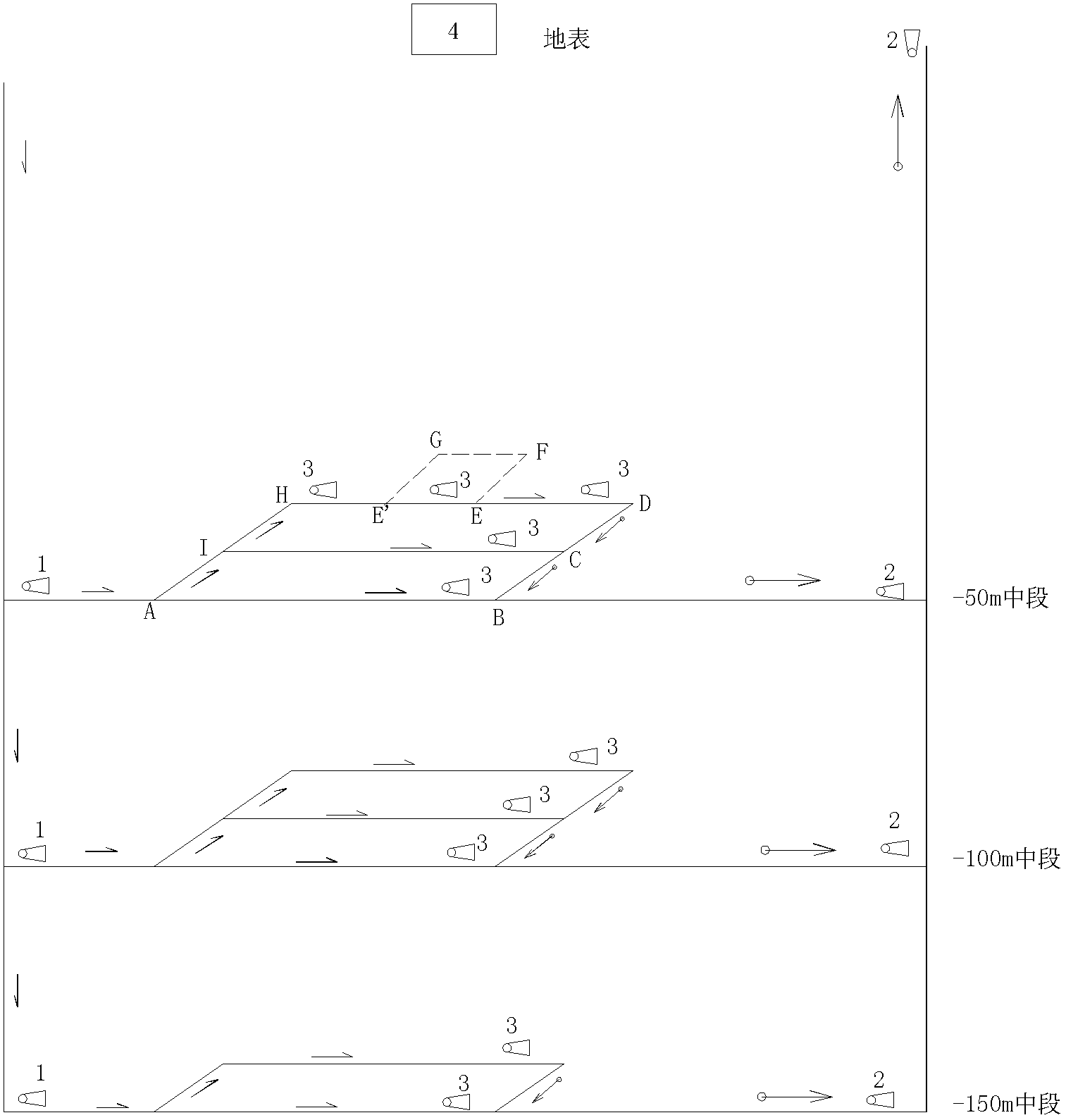

[0048] In order to further describe the present invention, a high-efficiency and energy-saving mine multi-stage machine station ventilation monitoring technology system of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

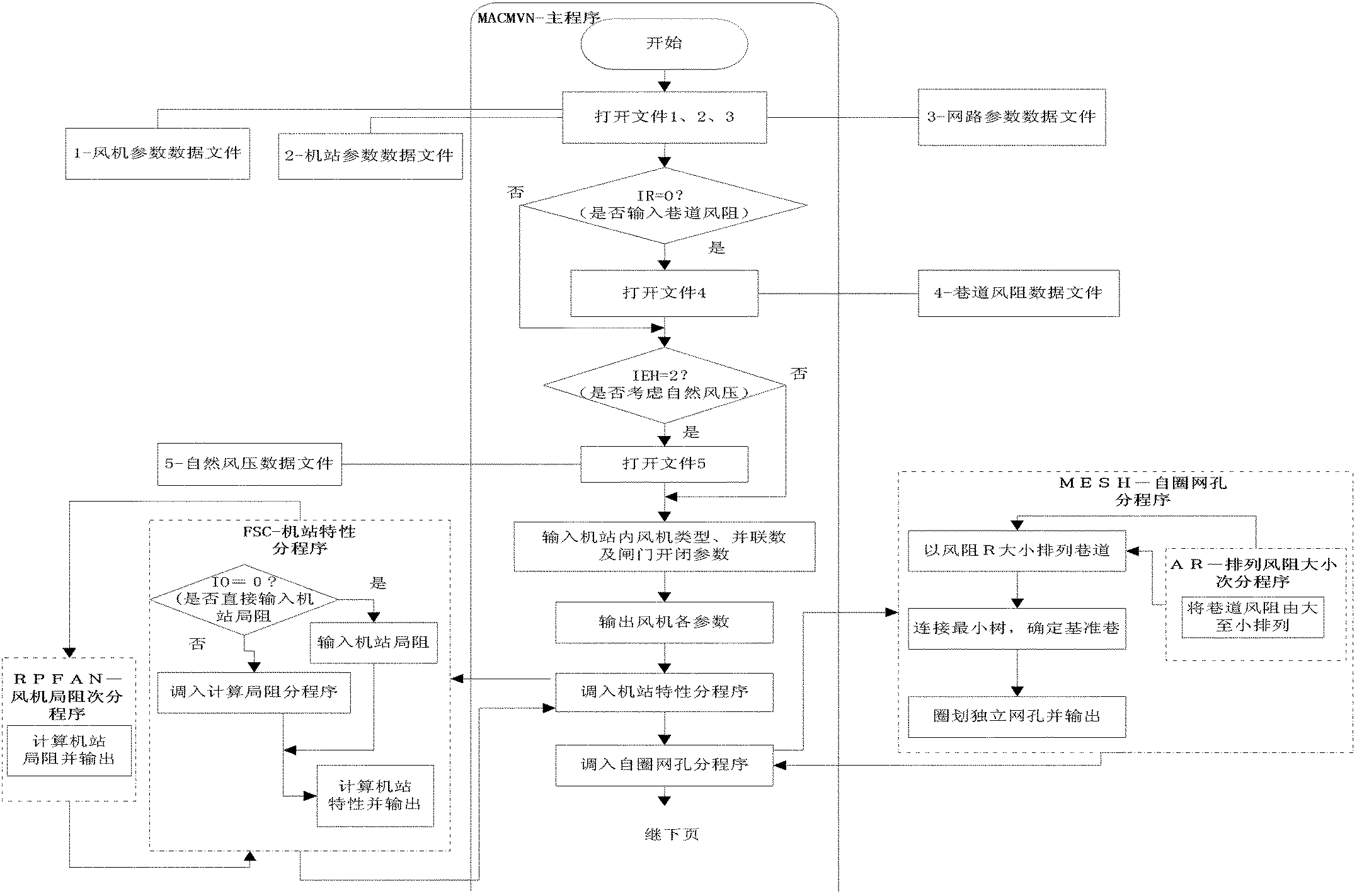

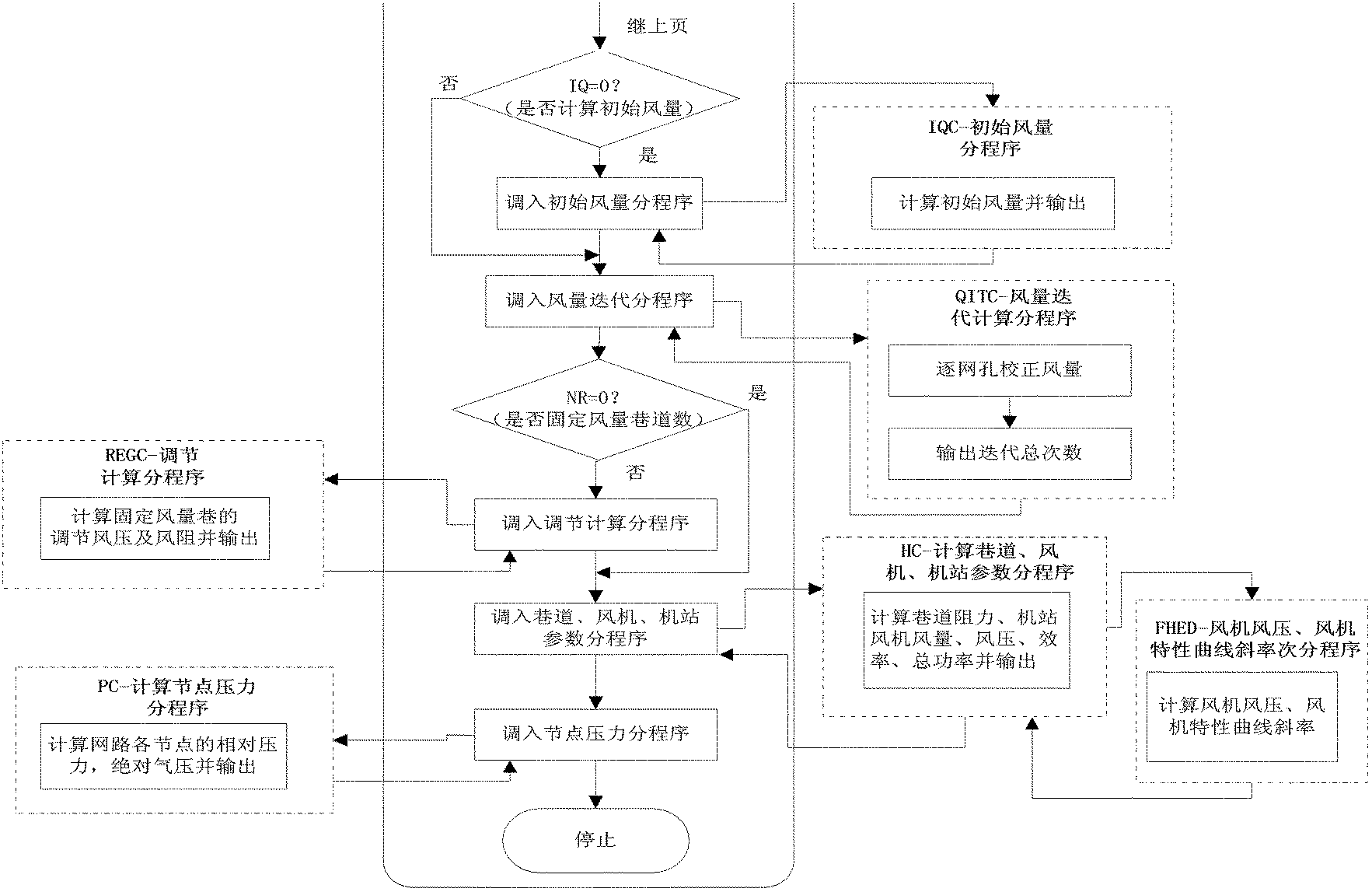

[0049] Depend on figure 1 The block diagram of the first half of the ventilation network program structure adopted by the high-efficiency and energy-saving mine multi-level machine station ventilation monitoring technology system of the present invention, figure 2 The second half of the block diagram of the ventilation network program structure adopted by the high-efficiency and energy-saving mine multi-level machine station ventilation monitoring technology system of the present invention shows that the multi-level machine station ventilation network program consists of 5 data files, 1 main program, It consists of 7 sub-programs and 3 sub-programs. The specific composition is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com