Voltage stabilization lifting support frame

A technology of voltage stabilization and screw lifting, applied in the directions of pillars/supports, pillars, mining equipment, etc., can solve the problems of inconvenient construction, waste of resources, inconvenient disassembly, etc., and achieve the effects of simple operation, large initial support force, and good mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

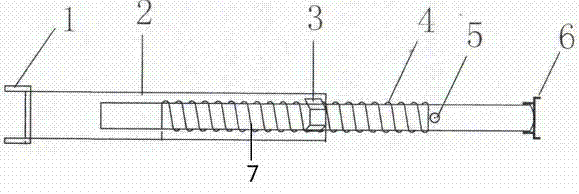

[0009] As shown in the figure, the pillar 2 is hollow, one end is welded with the top cap 1 outside, the other end is provided with a nut 3 inside, the upper end of the auxiliary column 4 is provided with a thread 7, the end of the silk thread 7 is provided with a handle hole 5, and the end of the auxiliary column 4 is provided with a base 6.

[0010] During operation, use the top hat 1 to withstand the pre-supported position, the base 6 to prevent sliding, and manually operate the handle hole 5 to rotate, rise counterclockwise, and descend clockwise until the pre-tightening force of the pillar is reached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com