Anti-winding built-in water seal apparatus

A water sealing device and anti-winding technology, which is applied in water supply devices, indoor sanitary plumbing devices, buildings, etc., can solve problems such as easy winding, upward overflow waterway blockage, etc., and achieve low cost, simple structure, anti-winding and anti-blocking Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

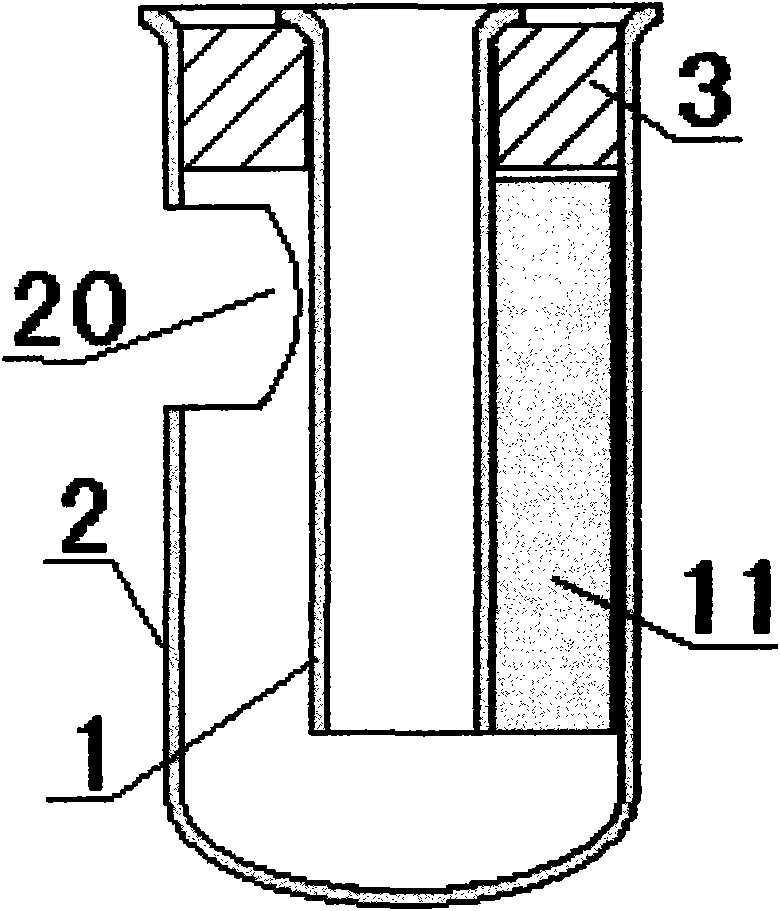

[0023] Embodiment one, such as figure 1 As shown, the anti-winding built-in water seal device of the present invention includes a small water riser 1, the outer circumference of the upper end of the small water riser 1 is fitted with a water storage bucket 2 with a lateral water outlet 20 on one side of the upper part, and a closed bottom. There is sufficient space for flowing water between the lower opening of 1 and the lower bottom surface of water storage bucket 2, and the vertical stop extending to the inner wall of water storage bucket 2 is formed on the opposite side of the small vertical pipe 1 to the side water outlet of water storage bucket 2 Bar 11 (or the other side opposite to the water outlet of the storage bucket side is shaped on the vertical limit bar that stretches out the small standpipe outer wall of the water). The outer periphery of the upper mouth of the small riser pipe 1 is fitted on the upper mouth of the water storage bucket 2 by the gasket 3 (or the ...

Embodiment 2

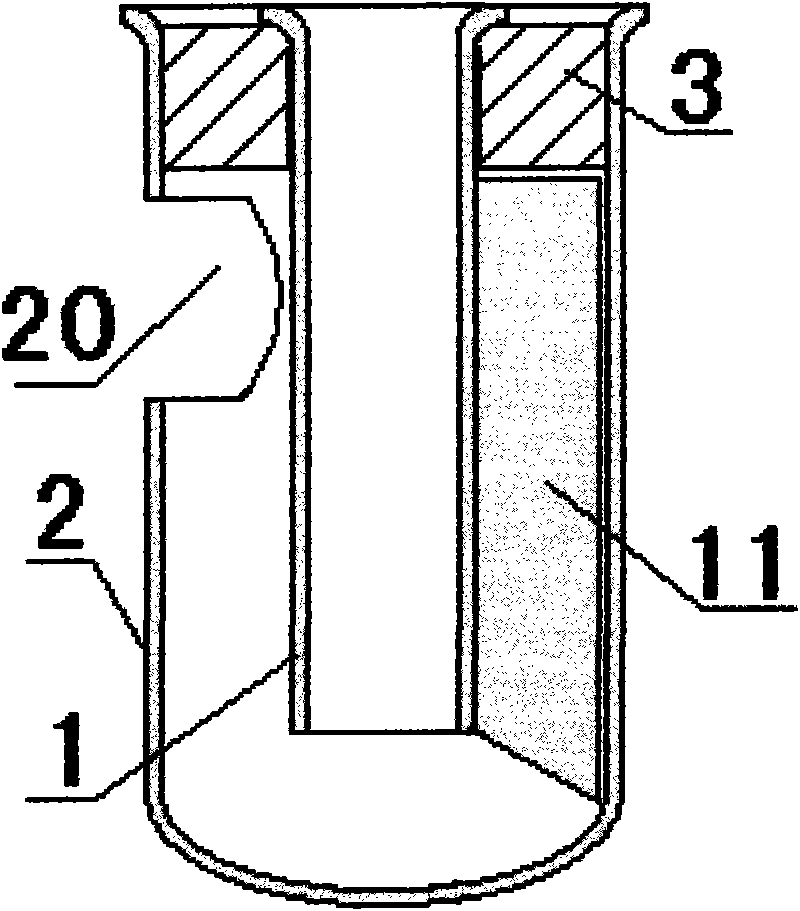

[0024] Embodiment two, such as figure 2 As shown, the difference between the anti-winding built-in water seal device of the present invention and Embodiment 1 is only that the inner side of the lower end of the vertical limiting strip 11 is flush with the lower wall adjacent to the small sewer riser 1, and the vertical limiting The lower end of the bar 11 is inclined downward from the inner side to the outer side.

Embodiment 3

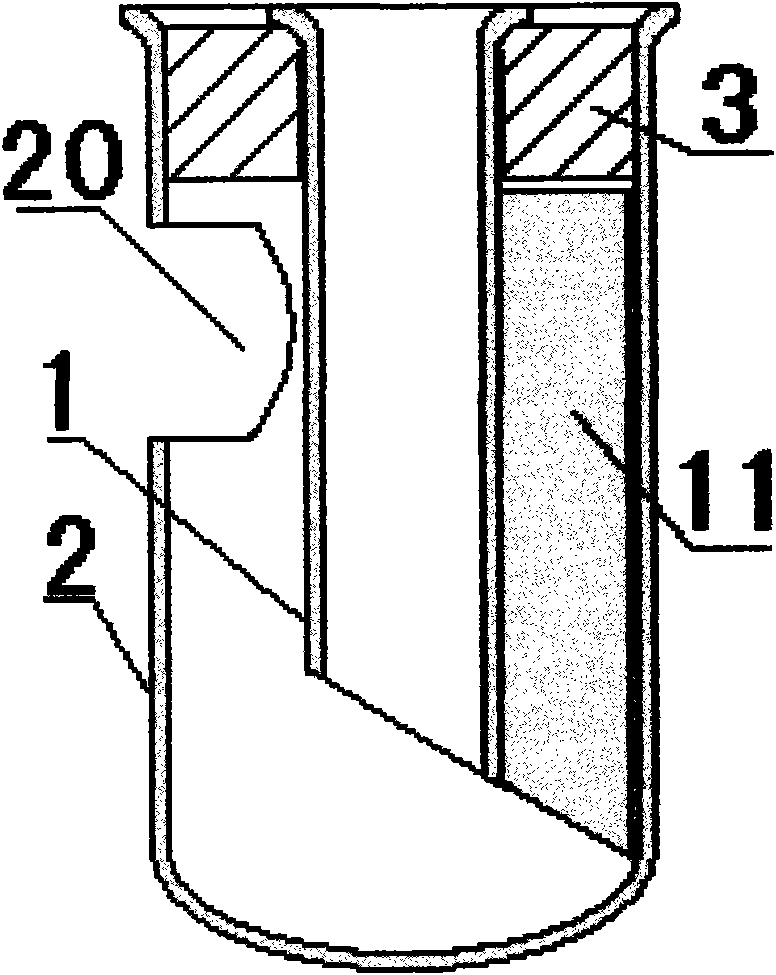

[0025] Embodiment three, such as image 3 As shown, the difference between the anti-winding built-in water seal device of the present invention and the second embodiment is only that the lower opening of the small vertical pipe 1 slopes downward from the water storage bucket 2 side to the water outlet side to the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com