Transport device comprising a transverse lifting unit with transport rollers

A technology of conveying device and conveying roller, which is applied in the directions of packaging, conveyor, conveyer objects, etc., can solve the problem of high cost, and achieve the effect of economical cost and simplified installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

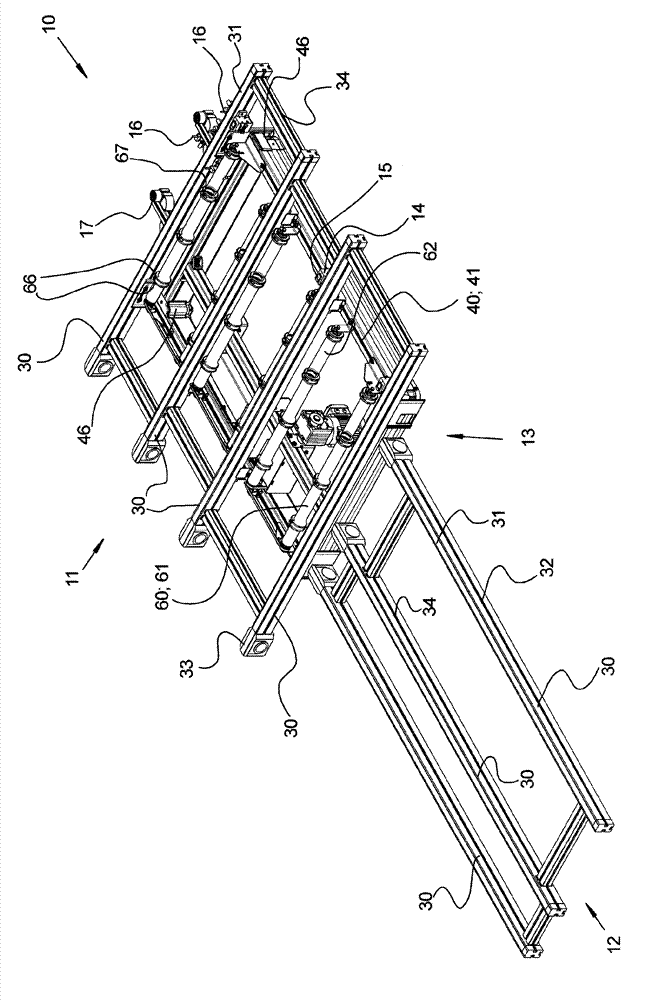

[0022] figure 1 A perspective view of the delivery device 10 according to the invention is shown. The conveying device 10 comprises a first conveying section 11 and a second conveying section 12 which diverges perpendicularly from the first conveying section 11 . The first conveyor section 11 contains four parallel conveyor belts 31 , while the second conveyor section 12 contains three parallel conveyor belts 31 . The conveyor belts 31 are each formed in the form of a conveyor module 30 according to DE 20 2008 011 613 U1. All content of DE 20 2008 011 613 U1 is referred to and becomes the content of this application.

[0023] All conveyor modules 30 are designed substantially identically, wherein the conveyor modules 30 of the first and second conveyor sections 11 ; 12 differ only in their length. Each delivery module 30 contains a support profile 32 which is extruded from aluminum. The continuous conveyor belt 31 is guided on the outside around the support profile 32 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com