Special tool for removing cotter pin on live line

A technology of special tools and cotter pins, which is applied in the direction of manufacturing tools, hand-held tools, etc., to achieve the effects of high reliability, elimination of hidden dangers, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following specific embodiments are only the best specific examples of the present invention, and should not be construed as limiting the structure of the present invention.

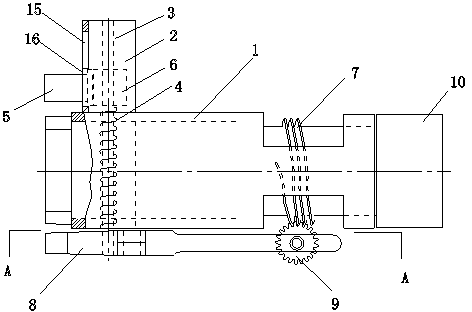

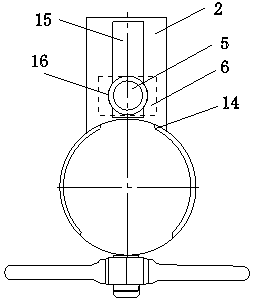

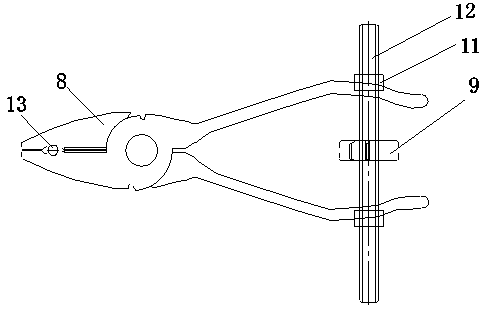

[0024] Special tools for live removal of cotter pins, such as figure 1 , figure 2 , image 3 As shown, a hollow sleeve 1 is included, and one end of the sleeve 1 is provided with a limiting groove 14, which corresponds to the upper and lower ends of the cotter pin 13, and the width of the upper opening of the limiting groove 14 is smaller than the width of the lower opening, respectively. It is used to block the annular head of cotter pin 13 and two cotter pins that are forked. In this embodiment, the outer diameter of the casing 1 is 24 mm, the inner diameter is 20 mm, and the length is 210 mm; The depth is 10mm.

[0025] A radial hole is arranged inside the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com