Flexible circuit board

A circuit board, bending technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of high price, easy damage, improper operation, etc., and achieve the effect of small size and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

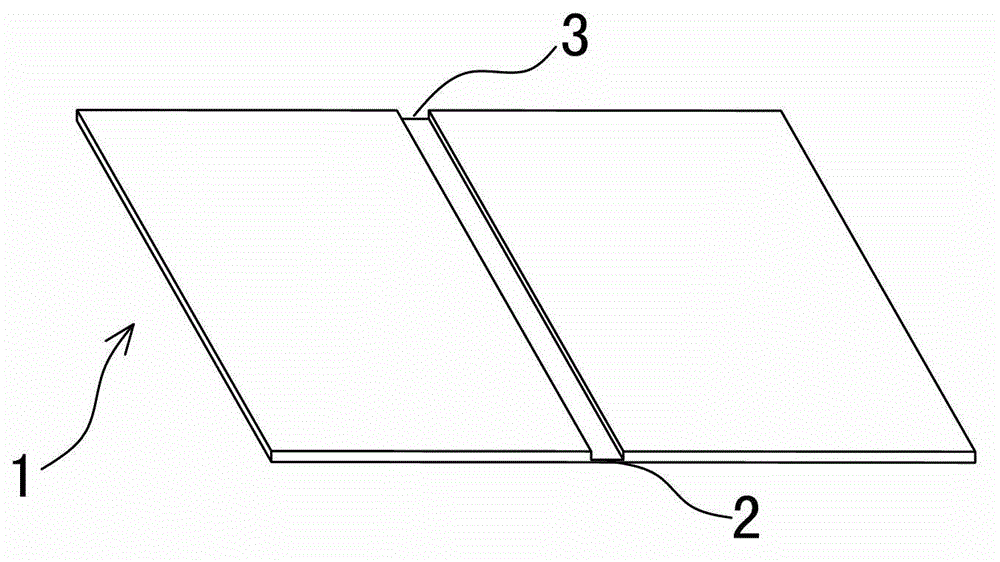

[0024] Example 1: Flexible circuit board

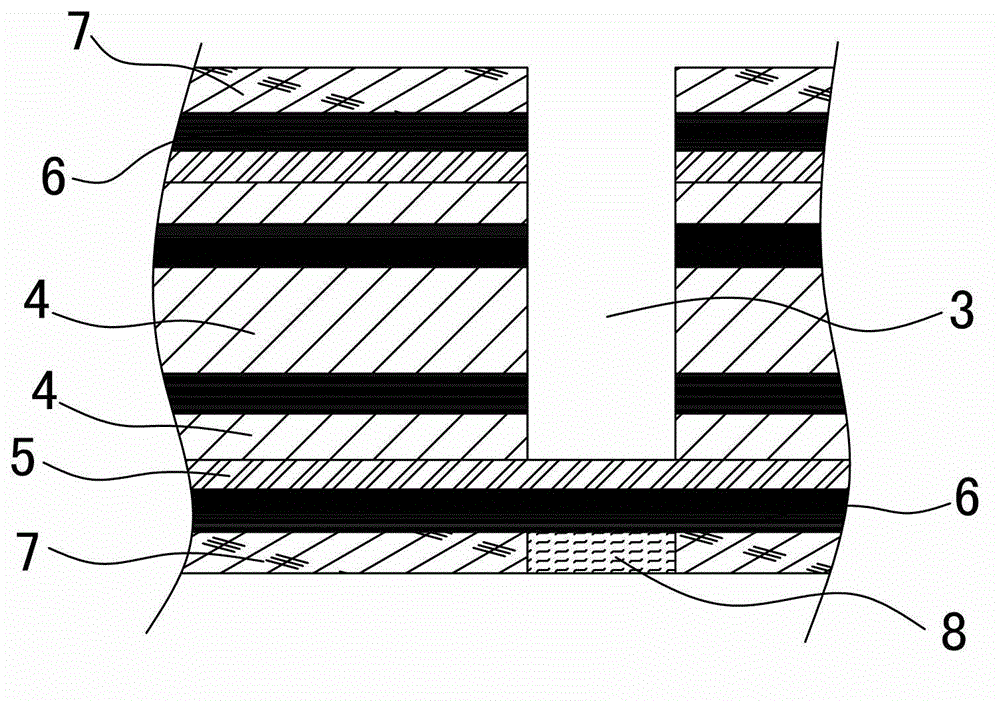

[0025] See attached figure 1 , attached figure 2 And attached image 3 As shown, the circuit board 1 is mainly composed of a core board and a number of prepregs laminated. The core board is a second prepreg 4 with a model number of 7628. The resin content of the second prepreg 4 is 45%, and the two sides of the second prepreg 4 are outward. A copper sheet 6, a second prepreg 4, a third prepreg 5 of model 1078, a copper sheet 6 and ink 7 are arranged in sequence.

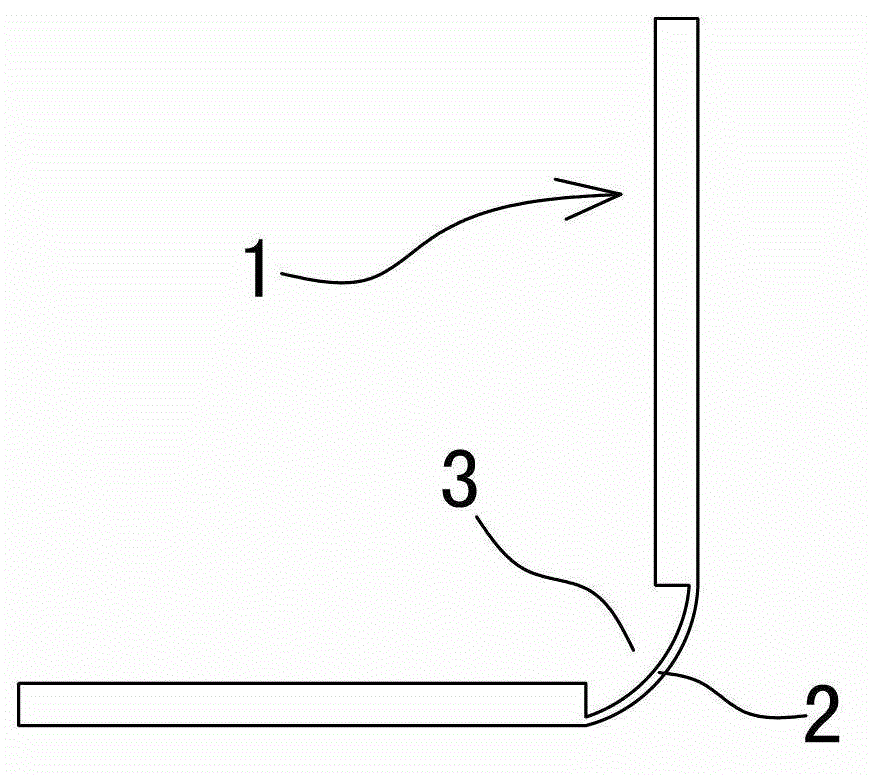

[0026] One side surface of the circuit board 1 is provided with a groove 3 for bending in the bending area 2, the length direction of the groove 3 is perpendicular to the bending direction of the circuit board 1, and the groove 3 runs through the circuit in the width direction Board 1, a third prepreg 5 and ink 7 are reserved between the groove bottom of the groove 3 and the other side surface of the circuit board 1, the resin content of the third prepreg 5 is 68%; the o...

Embodiment 2

[0027] Example 2: Flexible circuit board

[0028] See attached figure 1 , attached figure 2 And attached Figure 4 As shown, the center of the circuit board 1 is a second prepreg 4 with a type of 7628 resin content of 47%, and the two sides of the second prepreg 4 are successively composed of a first prepreg 9 with a type of 7628 and a copper sheet with a resin content of 52% from the inside to the outside. 6. The third prepreg 5, the copper sheet 6 and the ink 7 of the type 1078 with a resin content of 68% are laminated.

[0029] One side surface of the circuit board 1 is provided with a groove 3 for bending in the bending area 2, the length direction of the groove 3 is perpendicular to the bending direction of the circuit board 1, and the groove 3 runs through the circuit in the width direction Board 1, a first prepreg 9, copper sheet 6, third prepreg 5, copper sheet 6 and ink 7 are reserved between the groove bottom of the groove 3 and the other side surface of the circ...

Embodiment 3

[0030] Example 3: Flexible circuit board

[0031] See attached figure 1 , attached figure 2 And attached Figure 4 As shown, the center of the circuit board 1 is a second prepreg 4 with a model number of 7628 and a resin content of 49%. The two sides of the second prepreg 4 are sequentially composed of copper sheets 6 and a first prepreg with a model number of 7628 and a resin content of 54% from the inside to the outside. 9. The second prepreg 4 of model 7628 with a resin content of 49%, the first prepreg 9 copper sheet 6, the third prepreg 5 of model 1078 with a resin content of 68%, copper sheet 6 and ink 7 are laminated.

[0032] One side surface of the circuit board 1 is provided with a groove 3 for bending in the bending area 2, the length direction of the groove 3 is perpendicular to the bending direction of the circuit board 1, and the groove 3 runs through the circuit in the width direction Board 1, a first prepreg 9, copper sheet 6, third prepreg 5, copper sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com