Gate valve with function of reducing cavitation damage of valve plate

A gate valve and valve plate technology, applied in the gate valve field of valve plate, can solve the problems of reducing valve life, gate damage, cavitation damage, etc., and achieve the effect of reducing noise and cavitation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

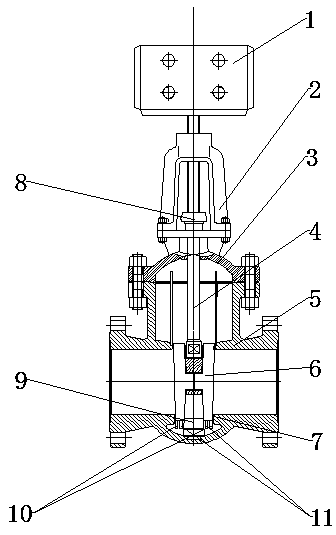

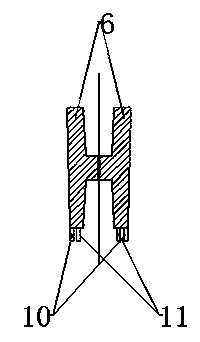

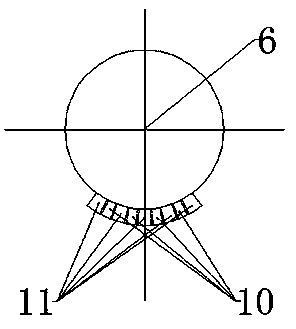

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a driving mechanism 1, a bracket 2, a valve cover 3, a valve stem 4, a valve body 5, a gate 6, a sealing surface 7, a shaft coupling 8 and a wedge block 9; the rotating shaft of the driving mechanism 1 is installed on the bracket Up and down, and through the coupling 8 and the valve stem 4, the two gates installed in the valve cover and the valve body move up and down, and the two gates are connected with the valve stem by welding. The block 9 and the valve stem are coaxially installed on the lower bottom of the valve body. The gate valve relies on the tension between the wedge-shaped block 9 and the H-shaped double gate composed of two gates 6 to achieve the sealing effect; the lower side of the gate 6 is installed with an inner comb. Teeth 11 and outer comb teeth 10, inner comb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com