Hybrid lift type impeller

A lift-type blade and lift-type technology, which is applied to wind turbines, hydroelectric power generation, wind turbines and other directions that are consistent with the wind direction, can solve problems such as weak working ability, insufficient working ability, and no directional adaptability. Good start-up and control of power speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

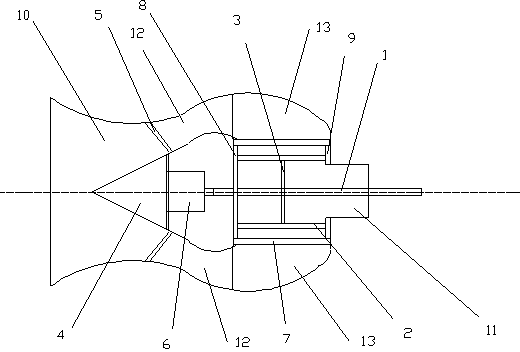

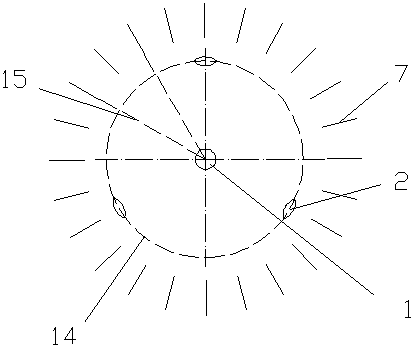

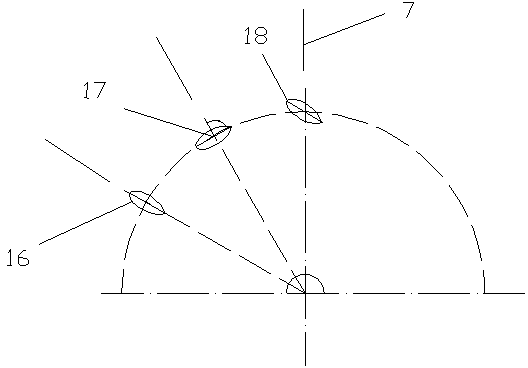

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the hybrid impeller of the present invention, the main body of the impeller includes a rotating shaft 1, on which two or more equal-section lift-type blades 2 are installed; one end of the blade is connected to a circular end cover 8 , the other end of the blade is connected with the annular end cover 9. The generator 6 driven by the impeller is fixed inside the closed conical flow guide 4, and the conical flow guide 4 is fixed inside the inlet flow channel 10 through the bracket 5, and the conical flow guide 4 is also located in the impeller upstream. A grille 7 is arranged around the impeller, and a water outlet channel 11 is arranged downstream of the impeller.

[0025] The fluid first enters the inlet channel 10, and under the influence of the conical shroud 4, the fluid enters the inlet channel 10 from the fluid inlet, passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com