System for tube push bench to go out of starting well and unkenneling construction method of tube push bench

A technology of pipe jacking machine and starting well, which is used in excavation, artificial island, water conservancy projects, etc., can solve problems such as affecting construction period, reinforcement, and inability to reinforce soil, achieving low labor and cost, wide application range and location. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

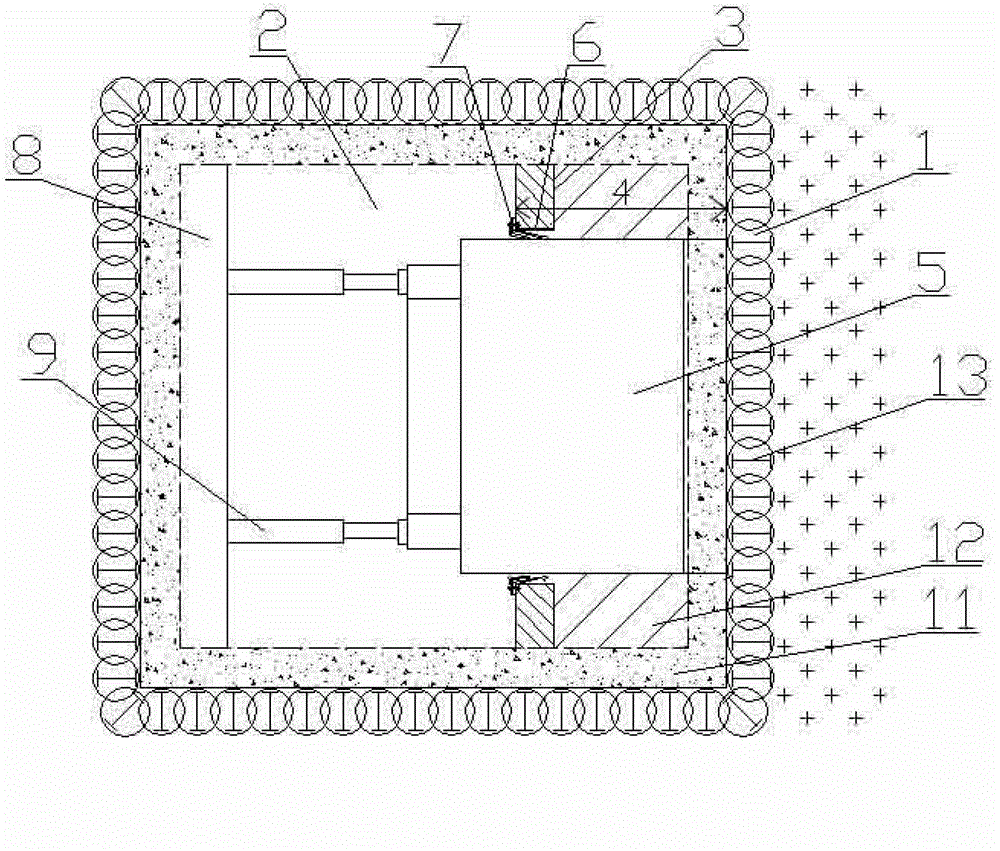

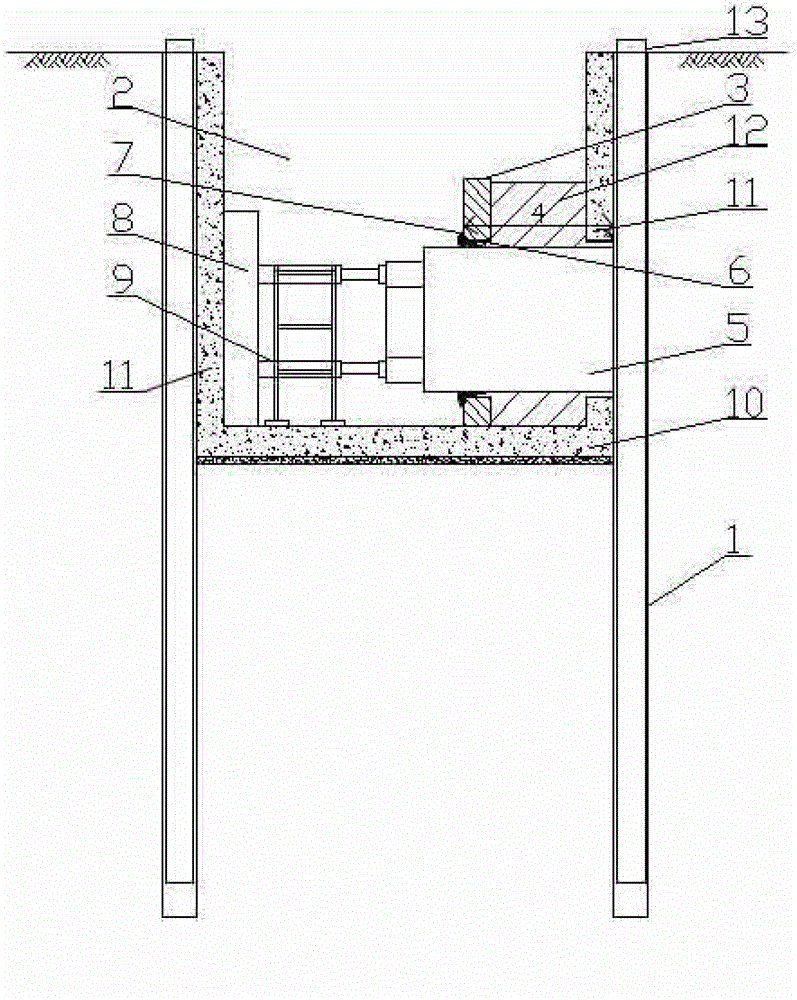

[0021] The following will combine figure 1 and figure 2 The soil reinforcement device provided by the present invention and the hole-exit construction method of the pipe jacking machine are described in detail, which is only a preferred embodiment of the present invention, and it can be considered that those skilled in the art can Next, modify and polish it according to the well-known common sense.

[0022] This embodiment provides a system for pipe jacking out of the originating shaft, including the enclosure structure 1 forming the origination shaft 2, the inner lining wall 11 arranged on the inner wall of the enclosure structure 1, and the The base plate 10, the jack 9, and the retaining wall 3 at the bottom of the launch shaft 2, the enclosure structure 1 adopts SMW piles, and the retaining wall 3 is vertically arranged in the launch shaft 2. The retaining wall 3 and the side lining wall 11 of the enclosure structure 1 are correspondingly provided with door openings for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com