Spinneret plate

A spinneret and spinneret technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of poor moisture absorption and moisture conductivity, poor gloss, poor moisture absorption and moisture conductivity, etc. Bright gloss, full color, easy to color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

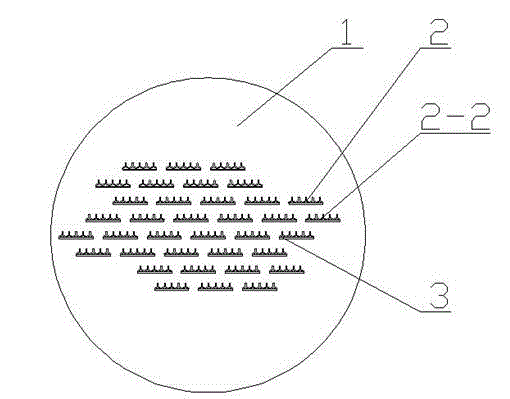

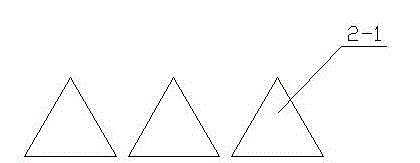

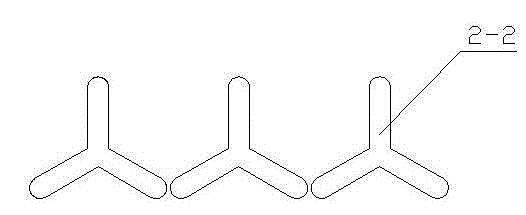

[0034] As a specific embodiment 1 of the present invention, this patent provides a spinneret capable of spraying zigzag-shaped fibers. The spinneret includes a spinneret 1 plate body and spinneret holes 2 distributed on the spinneret 1 plate body. The body of the spinneret 1 is a circular flat plate. The spinneret 1 of this patent can be a circular plate or a plate of other shapes. The manufacturer can choose according to the production equipment. figure 2 It is composed of 3 inner holes. The number of inner holes in the spinneret 2 of this patent can be 3-5, and the manufacturer can choose according to the product needs. The inner spinneret is a triangular hole 2-1. The wire hole can be either a triangular hole 2-1 or a trilobal hole 2-2. The manufacturer can choose according to the actual production needs. The length-to-width ratio of the spinneret is 4, and the length-to-width ratio of the spinneret of this patent is between 4 and 6. Any value between the two, 4.18 is the be...

Embodiment 2

[0036] As a specific embodiment 2 of the present invention, this patent provides a spinneret capable of spraying zigzag-shaped fibers. The spinneret includes a spinneret 1 plate body and spinneret holes 2 distributed on the spinneret 1 plate body. The body of the spinneret 1 is a circular flat plate. The spinneret 1 of this patent can be a circular plate or a plate of other shapes. The manufacturer can choose according to the production equipment. image 3 Shown is composed of 3 inner holes. The number of inner holes in the spinneret 2 of this patent can be 3-5. The manufacturer can choose according to the product needs. The spinneret is a trilobal hole 2-2. This patent The spinneret holes can be either triangular holes 2-1 or trilobal holes 2-2. The manufacturer can choose according to actual production needs. All the inner holes of the spinnerets in each spinneret hole 2 have the same shape. This patent All spinneret inner holes in each spinneret hole can have the same shape o...

Embodiment 3

[0038] As a specific embodiment 3 of the present invention, this patent provides a spinneret capable of spraying zigzag-shaped fibers. The spinneret includes a spinneret 1 plate body and spinneret holes 2 distributed on the spinneret 1 plate body. The body of the spinneret 1 is a circular flat plate. The spinneret 1 of this patent can be a circular plate or a plate of other shapes. The manufacturer can choose according to the production equipment. Figure 4 Shown is composed of 4 inner holes. The number of inner holes in the spinneret 2 of this patent can be 3-5. The manufacturer can choose according to the product needs. The spinneret is a triangular hole 2-1. The holes can be triangular holes 2-1 or trilobal holes 2-2. The manufacturer can choose according to actual production needs. All the inner holes of the spinnerets in each spinneret hole 2 have the same shape. All spinneret inner holes in the spinneret holes can have the same shape or different shapes, and different shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com