Chain-type conveyer

A technology of chain conveyors and conveyor chains, which is applied in the direction of conveyors, transportation and packaging, etc., which can solve the problems of high friction between materials and conveying troughs, damage to conveying troughs, and short service life, and achieve small transportation resistance, long service life, The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings, so as to further understand the purpose, scheme and effect of the present invention, but it is not intended to limit the protection scope of the claims of the present invention.

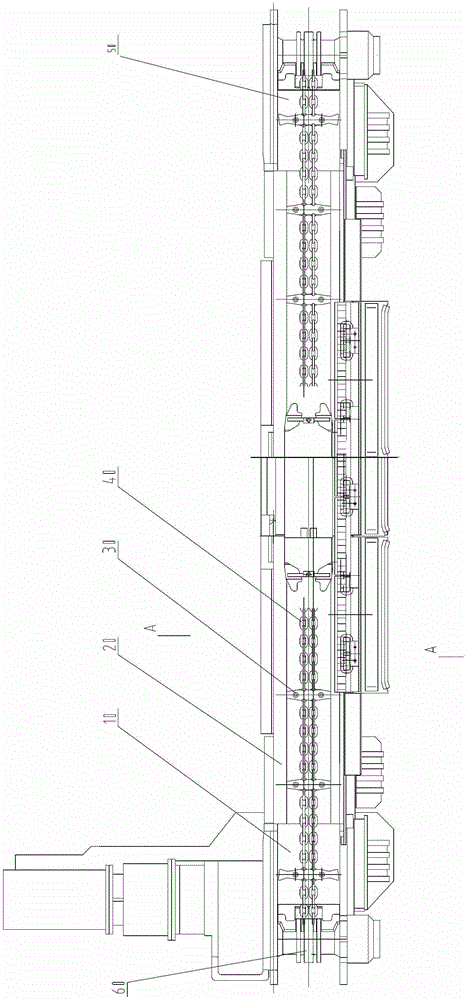

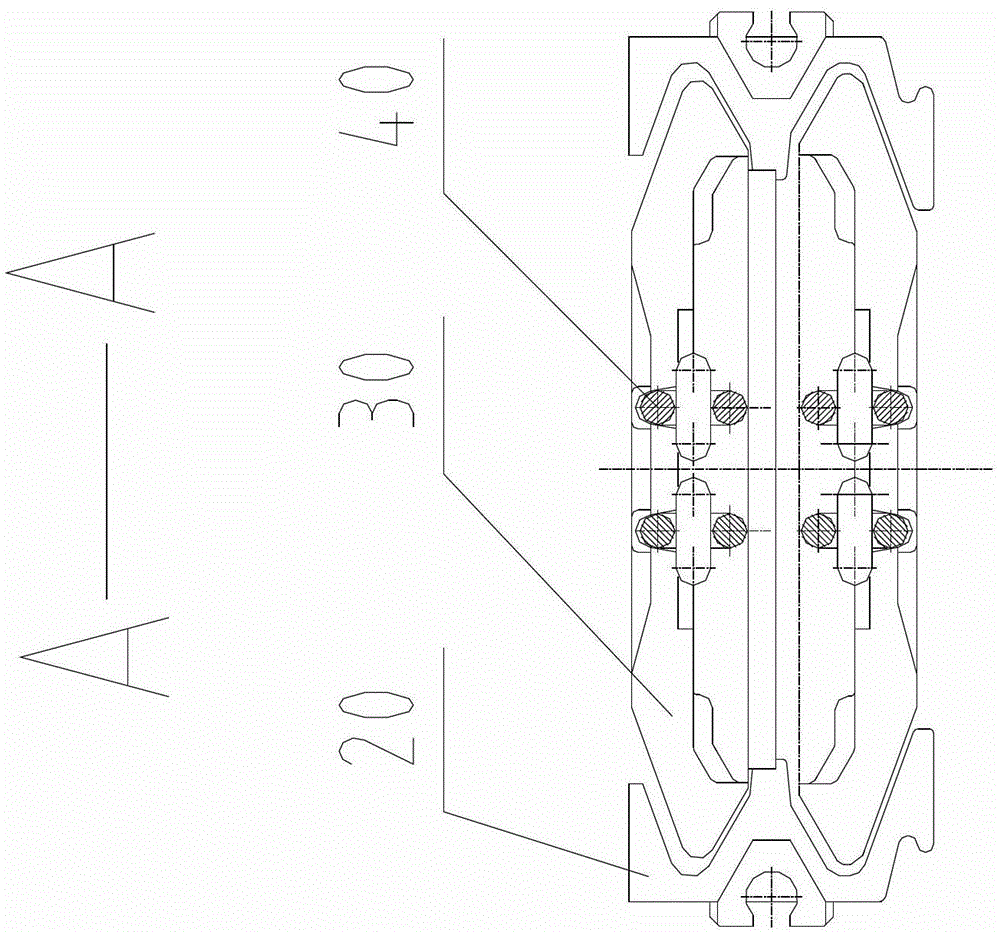

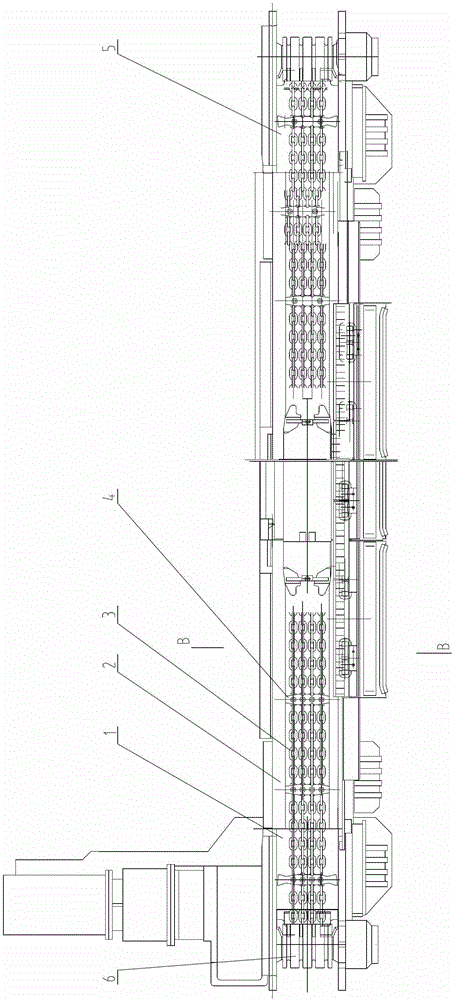

[0014] image 3 Be the embodiment structure schematic diagram of the structure diagram of chain conveyor, refer to image 3 , Figure 4 , the chain conveyor of the present invention comprises a head 1, a conveying trough 2, a conveying chain 3, a limit plate 4, a tail 5, a sprocket 6, etc., and is characterized in that: the sprocket is installed on the head 1 6. The conveying chain 3 is connected to the sprocket 6, and the conveying chain 3 is composed of more than two chains arranged in parallel, and the parallel arranged chain 3 is fixed on the limit plate 4 and installed in the conveying trough 2, The parallel arrangement and combination of multi-chain conveyor chains can reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com