Outer ring loading tool of tapered roller bearing

A tapered roller bearing and bearing technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of unfavorable processing and assembly, large deformation, low coaxiality, etc. The effect of improved accuracy and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

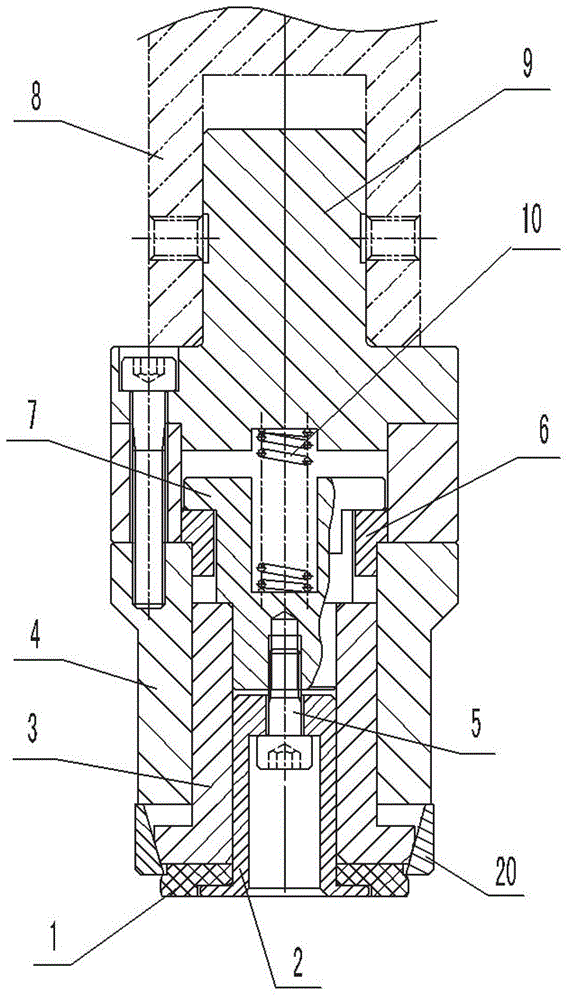

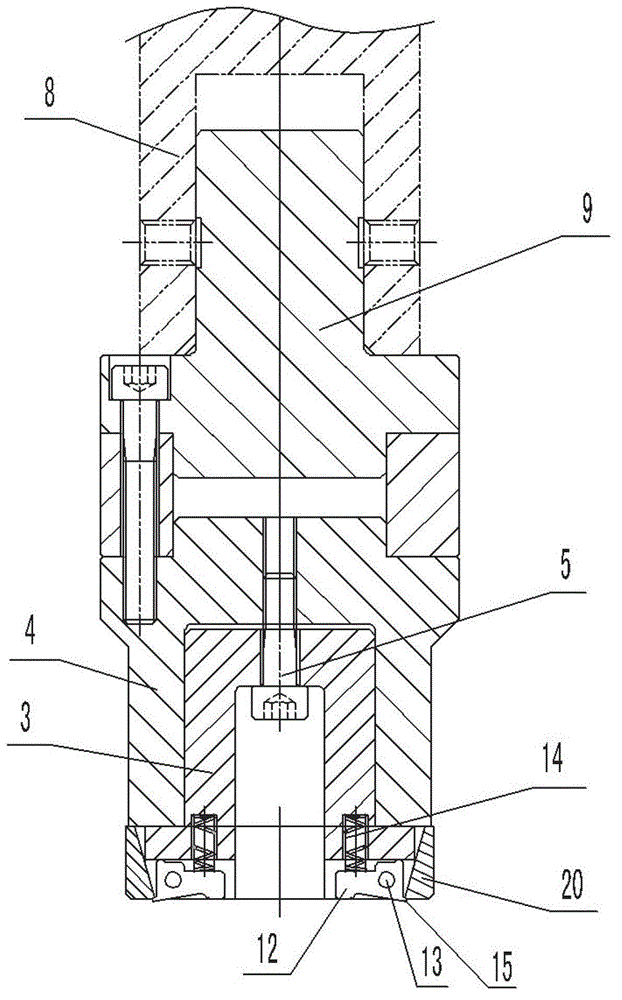

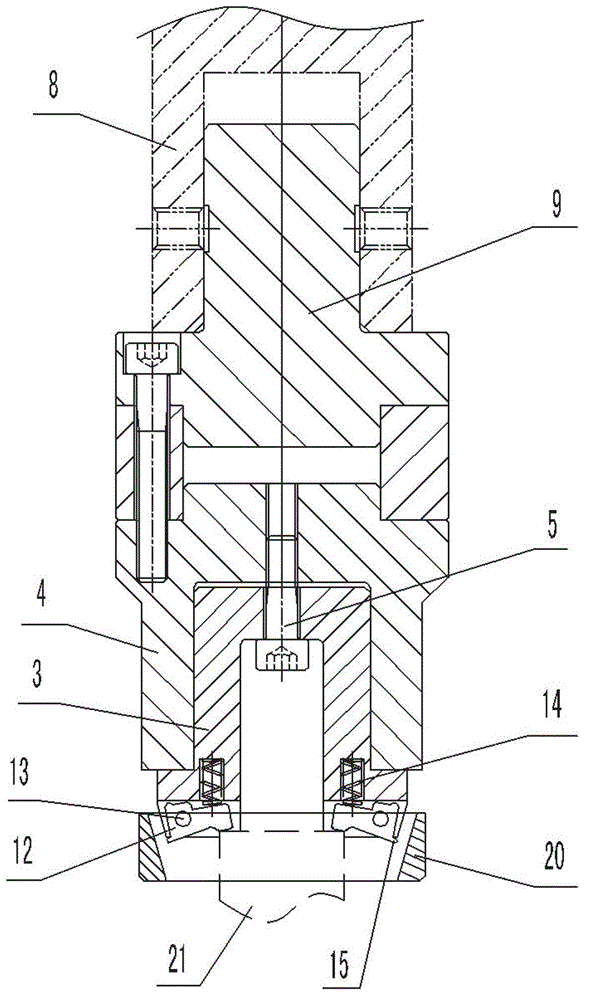

[0019] see figure 2 image 3 , the structural form of the tapered roller bearing feeding tooling in this embodiment is:

[0020] The bearing positioning shaft 3 is fixedly installed in the pressure head 4 through the screw 5, and three claws 12 are arranged on the bottom end surface of the bearing positioning shaft 3, and the claws 12 are installed on the bottom of the bearing positioning shaft 3 through the horizontal round pin 13, and the corresponding position A pawl spring 14 is arranged in the axial direction in the bearing positioning shaft 3; the pawl 12 of the lever structure uses the horizontal round pin 13 as a fulcrum for rotation, and the pawl spring 14 presses against the upper surface of the inner end of the pawl 12; the workpiece 21 It can act on the lower surface of the inner end of the claw 12; on the bottom edge of the outer end of the claw 12, there is a radially protruding flange 15, and the bearing outer ring 20 can be supported on the flange 15.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com