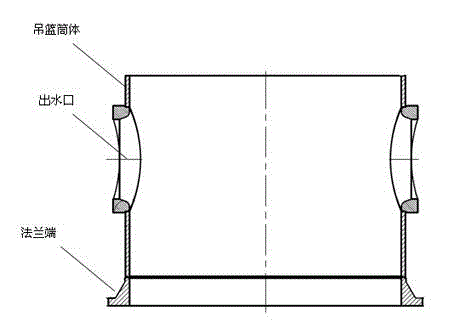

Device and method for correcting roundness of hanging basket barrel body

A hanging basket cylinder, orthopedic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of thinning wall thickness at the water outlet, and achieve short orthopedic construction period, strong operability, and short construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] based on the following Figure 2 to Figure 11 , specifically explain the preferred embodiment of the present invention.

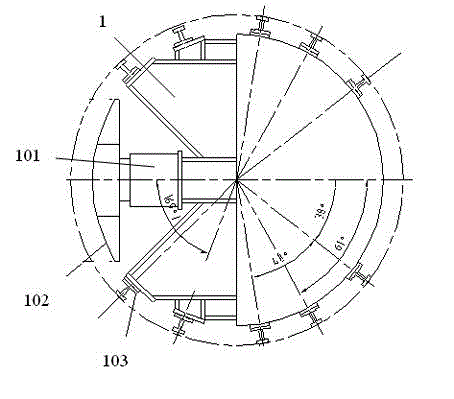

[0047] The invention provides an orthopedic device for correcting the roundness of a hanging basket cylinder, the device includes an orthopedic tool 1 and a supporting ring tool 2;

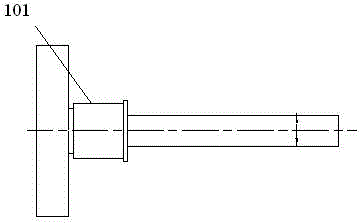

[0048] like figure 2 As shown, the orthopedic tooling 1 as a whole is a disc-shaped inner support, which includes a hydraulic jack 101 and several square support heads 103, and also includes a circular plug 102 arranged at the top of the hydraulic jack 101;

[0049] like image 3 As shown, the maximum output of the hydraulic jack (QF630T-20b) 101 is 600T;

[0050] The square support head 103 is detachable and can adjust the amount of ejection. The square support head 103 is used as the fulcrum of the orthopedic tooling 1 on the cylinder wall of the hanging basket cylinder during the correction;

[0051] In this embodiment, 10 square support heads 103 are distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com