High temperature and high pressure explosion limit tester, method and application for measuring explosion limit

An explosion limit, high temperature and high pressure technology, applied in the direction of material explosion, can solve problems such as the inability to effectively detect the explosion limit, and achieve the effect of reducing the wall effect and improving the wall effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

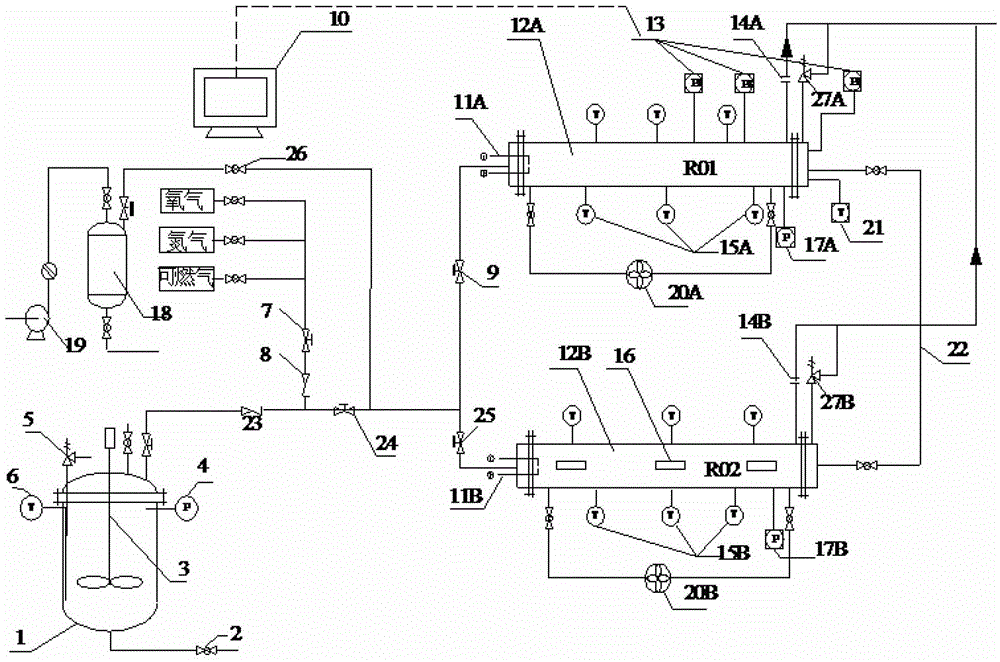

[0042] The invention provides a novel high-temperature and high-pressure explosion limit tester, which includes: a raw material gas supply device, an explosion measurement device, a vacuum generating device and a control device;

[0043] It is used to generate and transmit the gas or steam to be measured and oxygen and nitrogen to the explosion detection device. The gas or steam to be measured, oxygen and nitrogen are delivered separately;

[0044] The explosion measuring device is mainly composed of a pressure sensor, a temperature sensor, and an igniter, and is used to determine the explosion limit, explosion pressure, and explosion temperature of the gas or vapor;

[0045] The vacuum generating device is used to vacuumize the explosion measuring device;

[0046] The control device is used for measuring, controlling and collecting experimental data generated during the experiment.

[0047] The raw material gas supply device includes an evaporator, on which a safety valve, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com