Precise adjustment auxiliary device for track board of high speed railway and adjusting method thereof

An auxiliary device and precise adjustment technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of delaying the project progress, difficult operation of bolts, overdraft of personnel, etc., to reduce configuration requirements, improve work efficiency, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

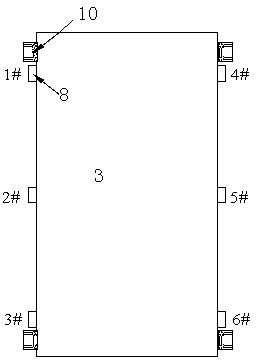

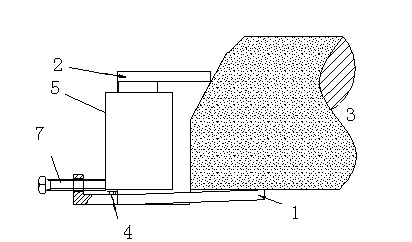

[0025] Such as figure 1 and figure 2 As shown, a high-speed railway track slab precision adjustment auxiliary device is installed on both sides of the track slab 3 and is located near the fine adjustment claw. It includes:

[0026] A bracket, which includes a bracket base 1 and a bracket top plate 2, the upper surface of the base has a pit, and one side extends below the track plate 3;

[0027] A plurality of balls 4, which are placed in the pits of the base 1;

[0028] A hydraulic jack 5, which is placed in the base 1 and on the ball 4; one end of the bracket top plate 2 is located at the top of the hydraulic front jack 5, and the other end contacts the side of the track plate 3;

[0029] A base bolt 7, which penetrates from the outside of the support base and leans against the side of the hydraulic jack 5;

[0030] In the high-speed railway track slab precision adjustment auxiliary device, the hydraulic jack 5 is a single-action thin jack.

[0031] A method for accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com