Multi-structure coupling magnetic field adaptability type rotating arc ion plating device

A magnetic field generator, multi-structure technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problem of target etching and poor coating uniformity, affecting the performance and life of coatings and films , Low target utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

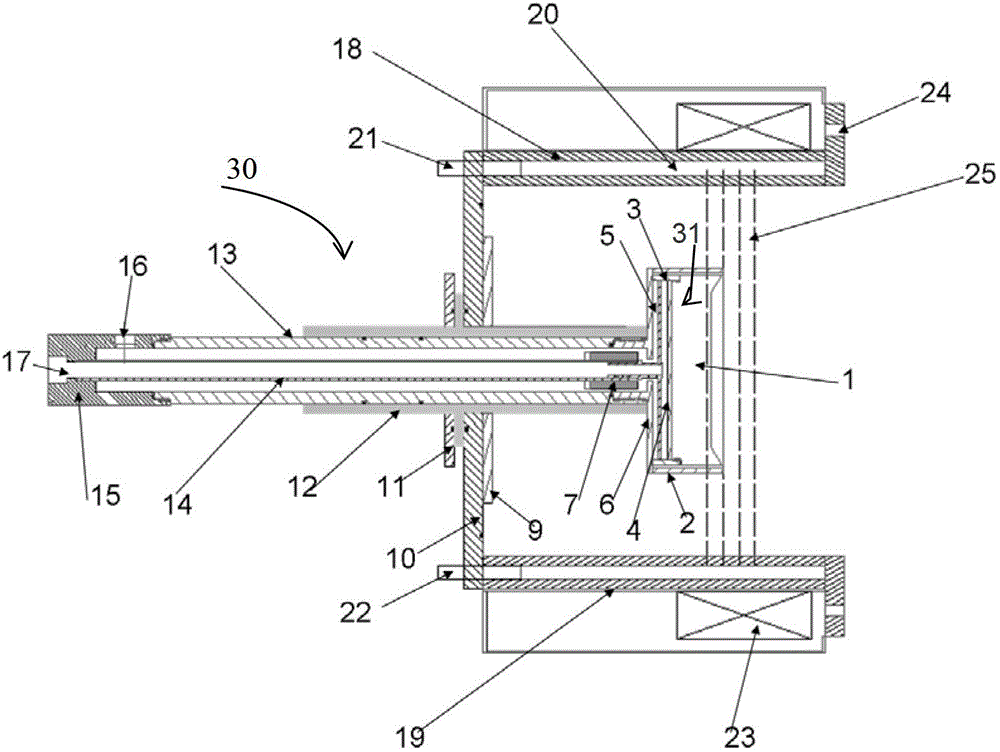

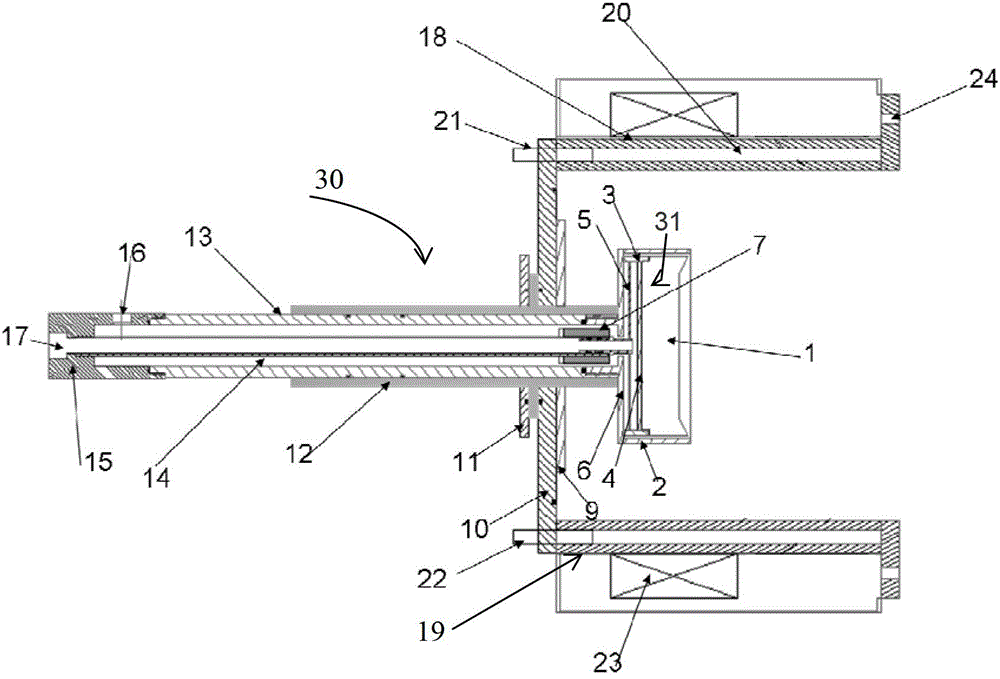

[0050] figure 1 It is one of the two-dimensional structural schematic diagrams of a multi-structure coupling magnetic field adaptive rotating arc ion plating device assisted by a single-two-pole rotating transverse magnetic field in Embodiment 1 of the present invention. The two-pole rotating transverse magnetic field generating device and the target are close to the end of the flange. figure 2 It is the second schematic diagram of the two-dimensional structure of a multi-structure coupling magnetic field adaptive rotating arc ion plating device assisted by a single-two-pole rotating transverse magnetic field in Embodiment 1 of the present invention. The two-pole rotating transverse magnetic field generator and the target are close to the bottom of the flange. It can be seen from the figure that the single-type composite magnetic field-assisted ion plating arc source device assisted by a single-two-pole rotating transverse magnetic field adopts a compact, simple and adjustable...

Embodiment 2

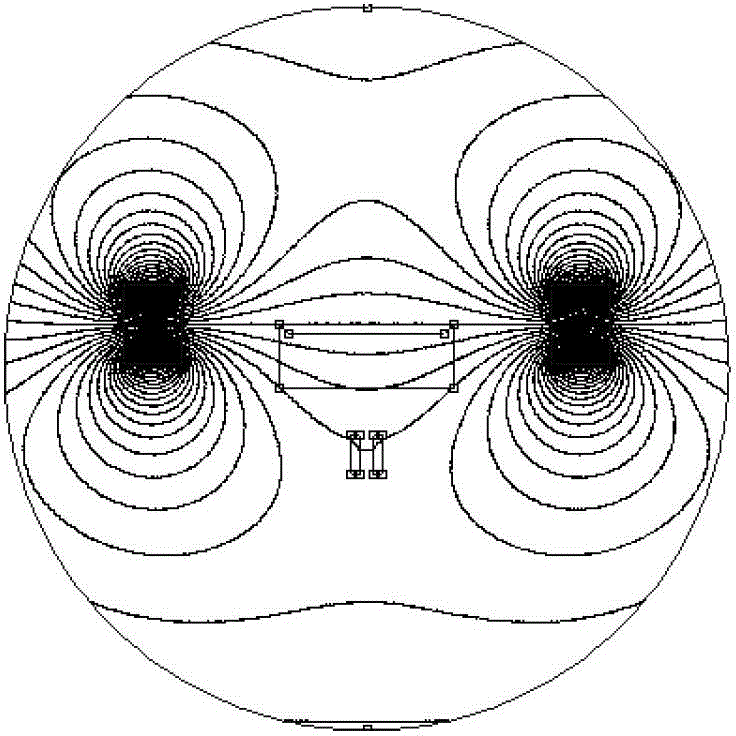

[0068] From image 3 It can be seen that when other magnetic fields do not work, the two-pole transverse magnetic field on the surface of the target is completely parallel to the target surface, forming an acute angle with the edge of the target pointing to the inside of the target. The high-speed rotation of the two-pole transverse rotating magnetic field can make the arc spot uniformly discharge on the entire target surface, reduce the power density, and reduce the emission of large particles. Because the transverse magnetic field is easy to make the arc spot move in a straight line at high speed, and the rotating transverse magnetic field can make the arc spot cloth run out of the target surface and distribute in the target surface, but if the rotation frequency and the magnetic field strength do not match, the transverse magnetic field with too large strength can be used alone It is easy to cause arc running and weaken the stability of arc spot discharge. However, the pre...

Embodiment 3

[0071] The transverse magnetic field has the effect of confining the plasma, which greatly reduces the transmission efficiency of the arc plasma. Most of the plasma is confined near the target surface, resulting in uneven deposition and a decrease in the rate. In order to further improve the transmission efficiency of the plasma, this Embodiment 3 of the invention extracts the purified high-density plasma through the focusing and guiding magnetic field at the end of the flange. Figure 6 It is the multi-structure coupling magnetic field adaptable rotating arc ion plating of the embodiment 3 of the present invention that the coupling magnetic field structure is a two-pole rotating transverse magnetic field coupled with a flange end focusing and guiding magnetic field (with a yoke) 27 of a certain strength to form a two-type composite magnetic field. Schematic diagram of the two-dimensional structure of the device. The focusing and guiding magnetic field generator 28 is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com