Method for detecting anisotropism P-wave of fractures of working face of mine

A technology of anisotropy and detection method, which is applied in the field of detection of abnormally developed cracks in the mine face to achieve the effects of high reliability, intuitive detection results and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

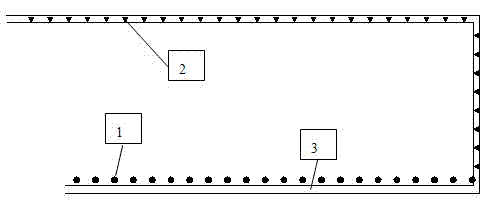

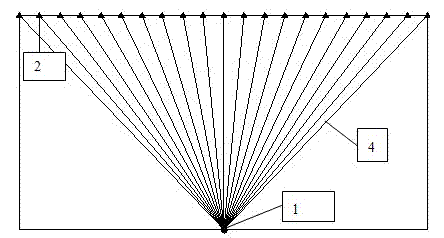

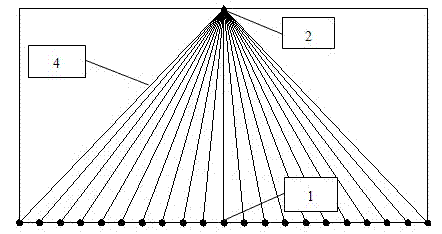

[0049] Embodiment 1: The anisotropic elastic P-wave detection method of the mine working face fracture comprises the following steps:

[0050] 1) First, in such as figure 1 The excitation shot point is arranged in the roadway on the side of the shot point shown, and the excitation parameters are as follows:

[0051] Location: the side of the mine working face close to the coal body to be detected;

[0052] Excitation drilling depth: 2.5m;

[0053] Exciting dose: 0.3Kg;

[0054] Drilling position: It is necessary to detect the middle of the coal body, more than 1m away from the bottom plate;

[0055] Drilling direction: along the coal seam direction;

[0056] Stimulation point spacing: 8~16m;

[0057] Detonator type: instant detonator;

[0058] Loading gun: positive charge, sealing mud to seal the whole hole.

[0059] 2) Second, in the case of figure 1 The detector point is arranged in the roadway on the side of the detector point shown, and the receiving parameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com