Second harmonic generation-based method for obtaining critical rotation speed of steam turbine rotor

A steam turbine rotor and critical speed technology, applied in the direction of linear/angular velocity measurement, velocity/acceleration/impact measurement, measuring device, etc., can solve the problems of large error between calculated value and actual measured value, limitations of actual measurement method, etc., and achieve small error and accuracy High degree of effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

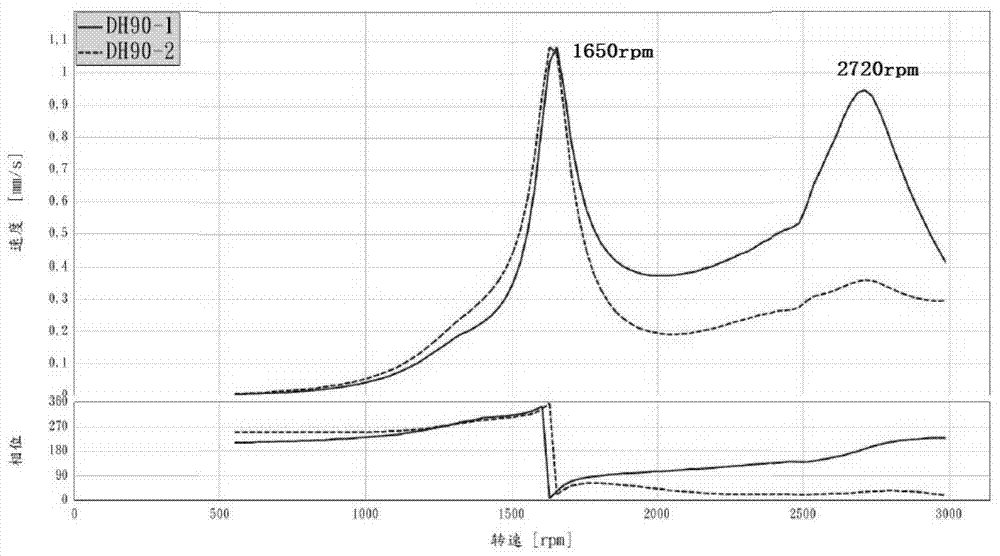

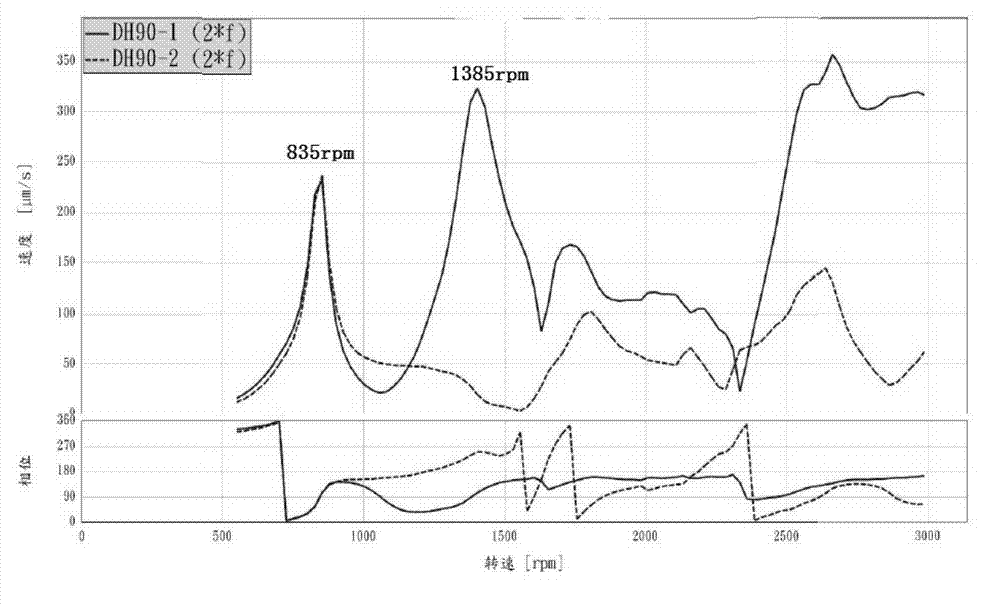

[0012] Specific implementation mode one: as Figure 1~2 As shown, the method for obtaining the critical speed of the steam turbine rotor based on double frequency described in this embodiment is implemented according to the following steps:

[0013] Step 1. Determine the position of the critical speed: increase the speed of the rotor of the steam turbine to 1800rpm, and then determine the position of the critical speed using the double frequency Bode diagram in the vibration monitoring system of the steam turbine;

[0014] Step 2, obtaining the first-order critical speed of the steam turbine rotor: multiply the value of the first-order critical speed position of the double-frequency Bode diagram in step 1 by two, and the obtained product value is the first-order critical speed of the steam turbine rotor;

[0015] Step 3. Obtain the second-order critical speed of the steam turbine rotor: multiply the value of the second-order critical speed position in the double-frequency Bode...

specific Embodiment approach 2

[0018] Embodiment 2: In step 2 of this embodiment, the error range of the first-order critical rotational speed of the steam turbine rotor is 10-30 revolutions. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: In step 3 of this embodiment, the error range of the second-order critical speed of the steam turbine rotor is 50-90 revolutions. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com