Pitch variation measuring device for large-size straight toothed spur gear

A spur gear, deviation measurement technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of unstable contact state, heavy instrument, large modulus, etc., to achieve stable contact state, ensure measurement accuracy, and improve repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

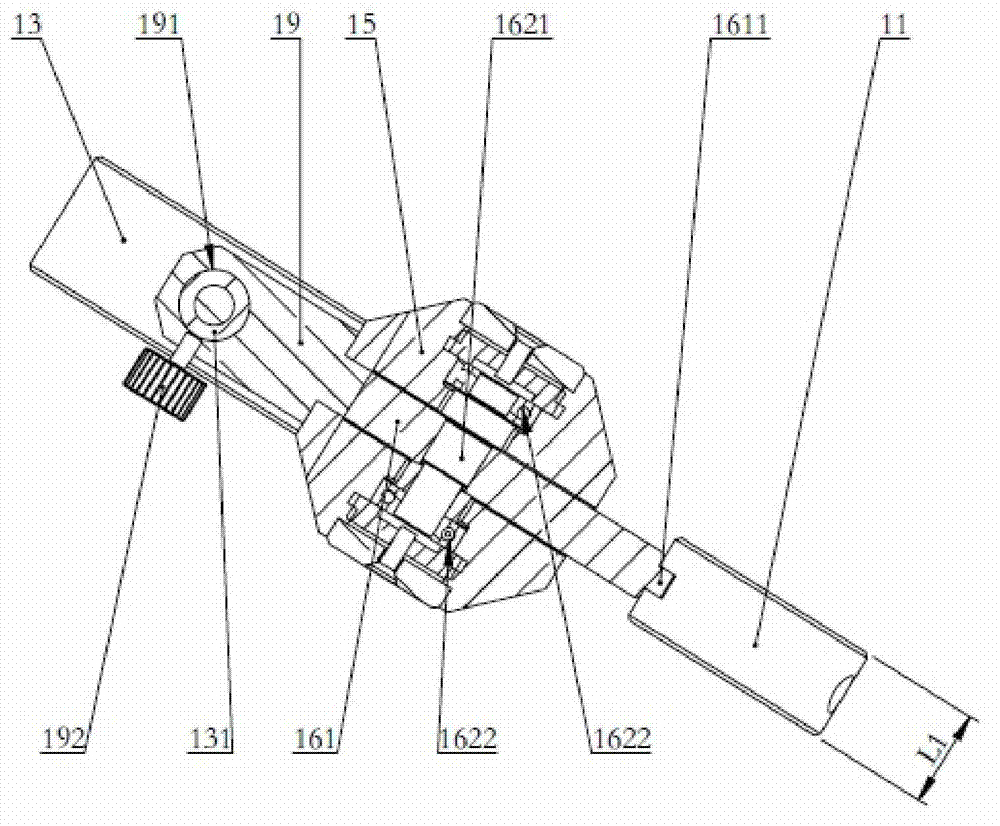

[0029] Such as figure 1 As shown, for the technical solution one, when used for measuring the pitch deviation of odd-numbered gears, the device of the embodiment of the present invention includes a front positioning element 11, a rear positioning element 12, a center distance measuring gauge 13, a radial measuring Meter 14, a lever mechanism 16, and a body 15 as an assembly reference; when used for even-numbered gear pitch deviation measurement, the device in the embodiment of the present invention also includes an independent inter-tooth measurement accessory 3, wherein the front Both the positioning element 11 and the rear positioning element 12 are a cylinder (for reasons such as connection, the surface of the cylinder that has no effect on the measurement and positioning has been removed), and their diameters are the same; The measuring gauge head 14 is a digital dial gauge; the front positioning element 11 and the rear positioning element 12 are located on the same side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com