Reciprocating type tilting tray compressor structure

A swash plate compressor, reciprocating technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, machines/engines, etc., can solve the problems of low compressor working efficiency and large driving resistance, and reduce the driving torque and reduce the Driving resistance, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

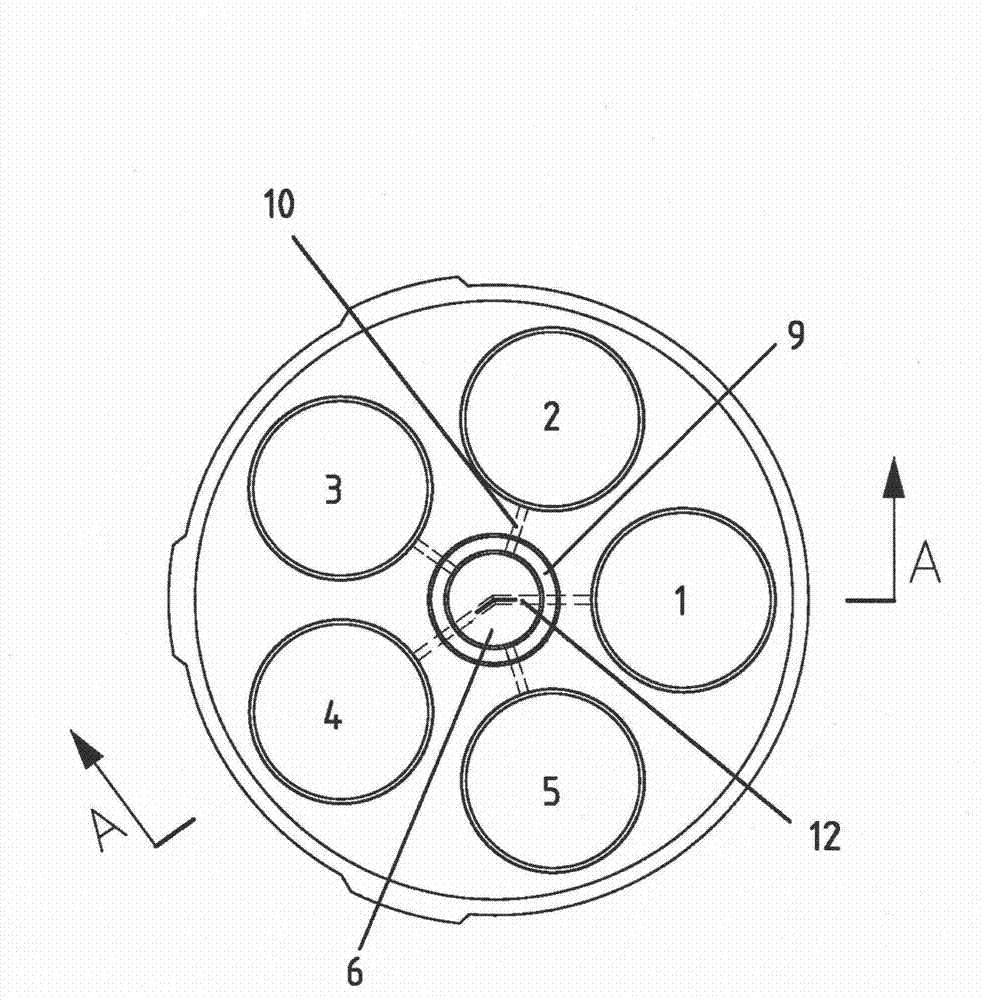

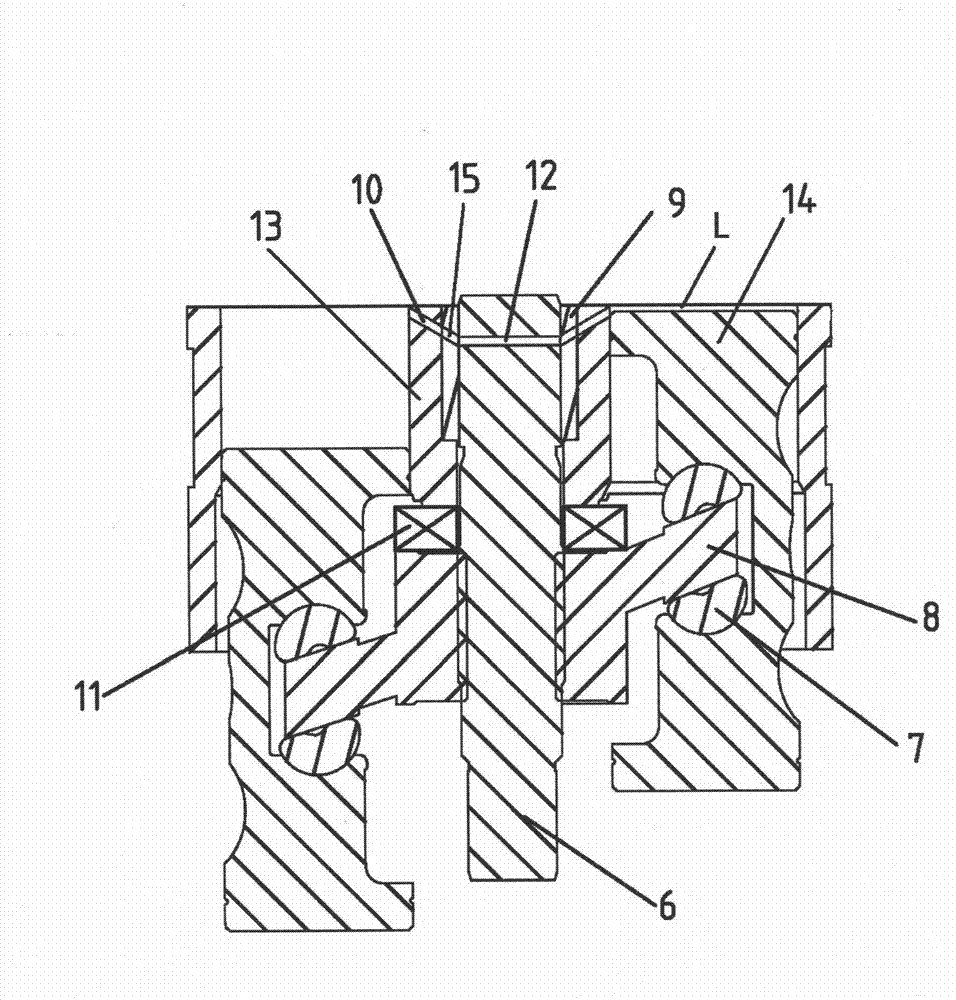

[0018] The present invention is a reciprocating swash plate compressor structure, such as figure 1 , figure 2 Shown is a structural schematic diagram of a reciprocating swash plate compressor structure. A main shaft 6 is installed in the center of the cylinder body 13, and the sealing shaft sleeve 9 is used to seal between the cylinder body 13 and the main shaft 6. The hemisphere 7 is connected with the piston 14, the main shaft 6 is provided with a main shaft ventilation hole 12, the cylinder body 13 is provided with a cylinder ventilation hole 10, and the sealing sleeve 9 is provided with a connection hole 15. Both ends of the main shaft air hole 12 are respectively connected with two adjacent connection holes 15 . The connecting hole 15 communicates with the cylinder vent hole 10 , and the cylinder vent hole 10 corresponds to the connecting hole 15 . The clearance L is located at the end face of the cylinder in the cylinder block 13 , and the clearance L communicates wi...

Embodiment 2

[0025] The present invention is a reciprocating swash plate compressor structure, the number of cylinders in the cylinder is 4 cylinders, the angle between the two sides of the main shaft vent hole is 180°, and the main shaft must be rotated 90° clockwise to connect the main shaft vent hole with the other The two cylinders are connected. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com