Novel precast slab assembled floating track bed

A technology of floating ballast bed and prefabricated slabs, which is applied in the field of rail transit, can solve the problems of consuming manpower and material resources, restricting construction speed, time-consuming and laborious, etc., and achieve the effects of improving construction efficiency, convenient assembly, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

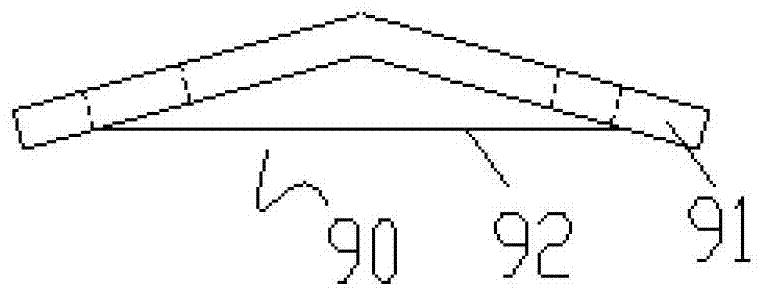

[0040] Such as Figure 8 As shown, the novel prefabricated slab-assembled floating ballast bed of the present invention comprises: a plurality of floating ballast bed prefabricated slabs sequentially laid in front and rear order; multiple connecting devices for fixedly connecting two adjacent floating ballast bed prefabricated slabs, using A plurality of floating ballast bed prefabricated panels are sequentially connected into one to form an assembled floating ballast bed.

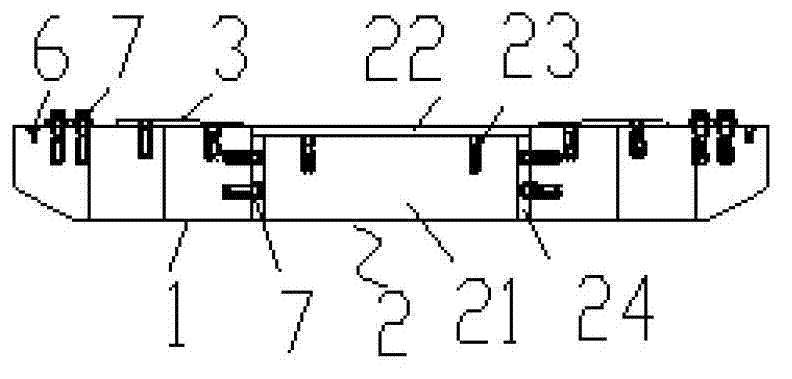

[0041] Among them, such as figure 1 , 2 As shown, each floating ballast bed prefabricated slab of the present invention includes: a prefabricated slab main body 1, groove structures 2 are respectively provided at both ends of the prefabricated slab body; The outer sleeve device 4 for the inner sleeve of the vibration isolator is arranged corresponding to the rail support platform 3; the first casing group 7 placed in the prefabricated slab main body 1 is located on both sides of the groove structure 2; i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com