Tin dipped baseboard for glass sealed diode

A technology of glass-encapsulated diodes and immersion tin, which is applied in hot-dip plating process, coating, electrical components, etc., can solve the problems of short service life of the bottom plate, easily damaged magnetic force, short service life, etc., and achieve the degree of suppression of magnetic force attenuation, The effect of increasing the contact area and securing the magnetic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

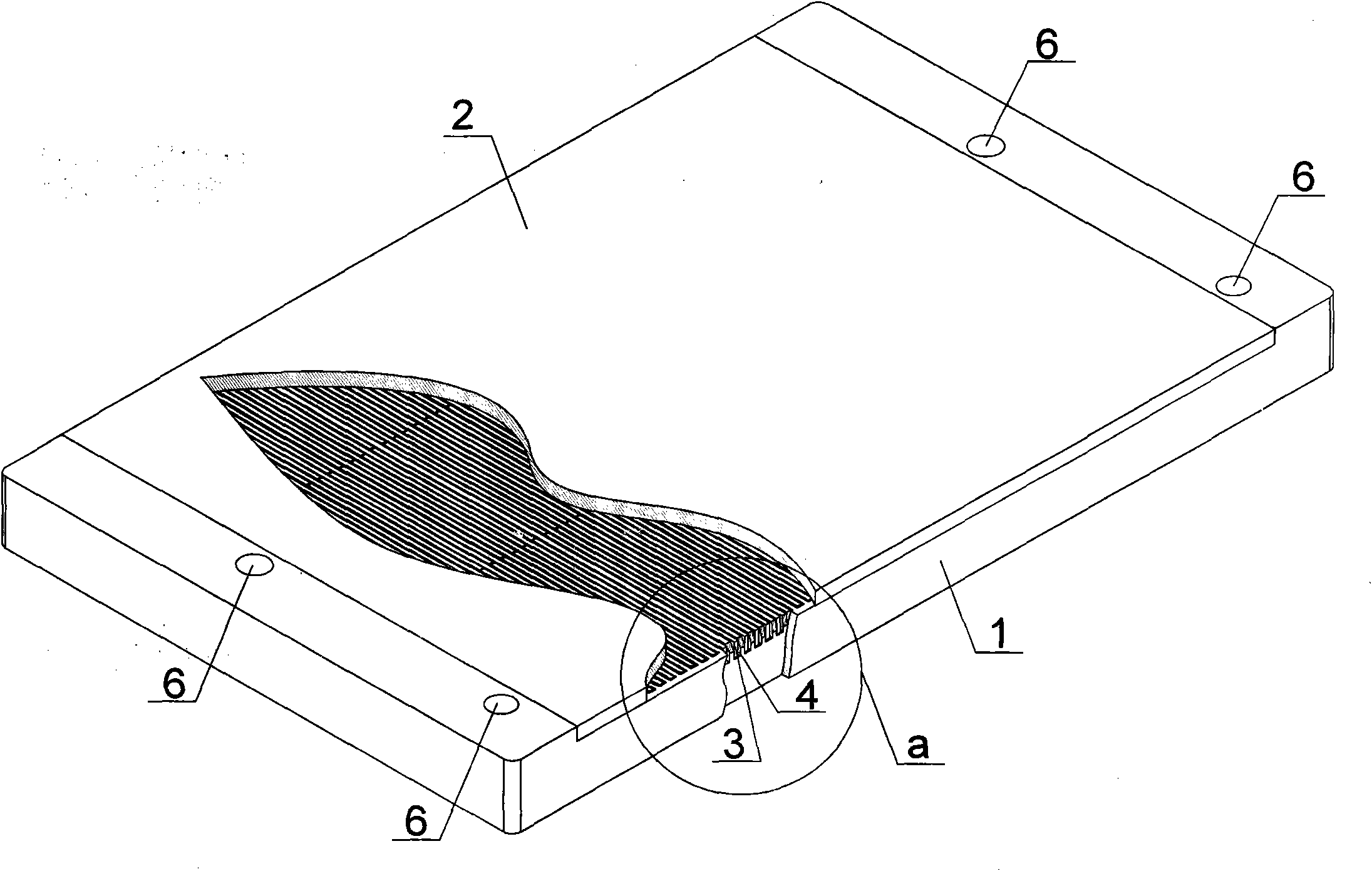

[0024] Below in conjunction with accompanying drawing, further description is carried out to the immersion tin base plate that the glass-encapsulated diode of the present invention is used.

[0025] Reference attached Figure 1 ~ Figure 4 , as shown in these figures, the immersion tin base plate used for the glass-encapsulated diode is composed of a substrate 1, a magnetic strip 3, and a panel 2. The substrate 1 is a non-magnetic metal plate on which There are several installation holes 6 and a recessed platform 5, and several parallel grooves 4 are arranged in the recessed platform 5; Magnetic strips 3 are placed in the grooves 4; the panel 2 is a metal plate with good magnetic permeability, and its Cover and fix on the upper surface of concave platform 5.

[0026] The magnetic strip 3 placed in the groove 4 is one or more permanent magnetic magnetic strips; when the magnetic strip 3 placed in the groove 4 is multiple, the arrangement of these magnetic strips is: connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com