Automatic inspection system of suspension belt conveyer

A belt conveyor, automatic inspection technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of low precision, economic loss, poor real-time performance, etc., to prevent belt tearing, reduce Effects of running resistance and wide availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

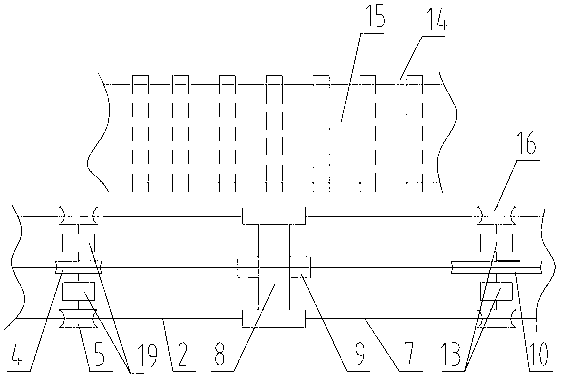

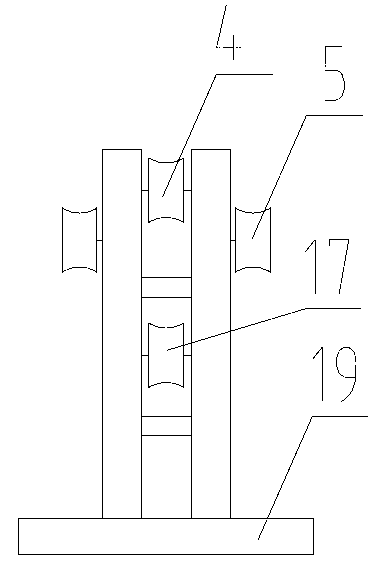

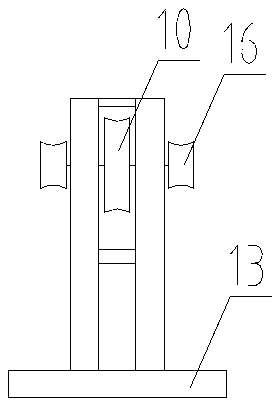

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automatic inspection system of the suspension type belt conveyor of the present invention is mainly composed of a driving device 1, a rope tightener 3, a traction wire rope 2 connected to the driving device 1, and a guiding device arranged on one side of the belt conveyor. Device 8, suspension cable guide rail 7 and inspection bin 9 constitute. Among them: the driving device 1 is composed of a motor, a reducer and a drum wound around the traction wire rope 2; the traction wire rope 2 is provided with a rope tightener 3, and two support supports on the left and right are set in the conveyor belt section of the belt conveyor. Two pairs of support wheels 5,16 are respectively arranged on the support, and the two pairs of support wheels 5,16 on the left and right are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com