Numerical control lathe for processing worm gears

A technology of CNC lathes and worm gears, which is applied in the directions of worm gears, components with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

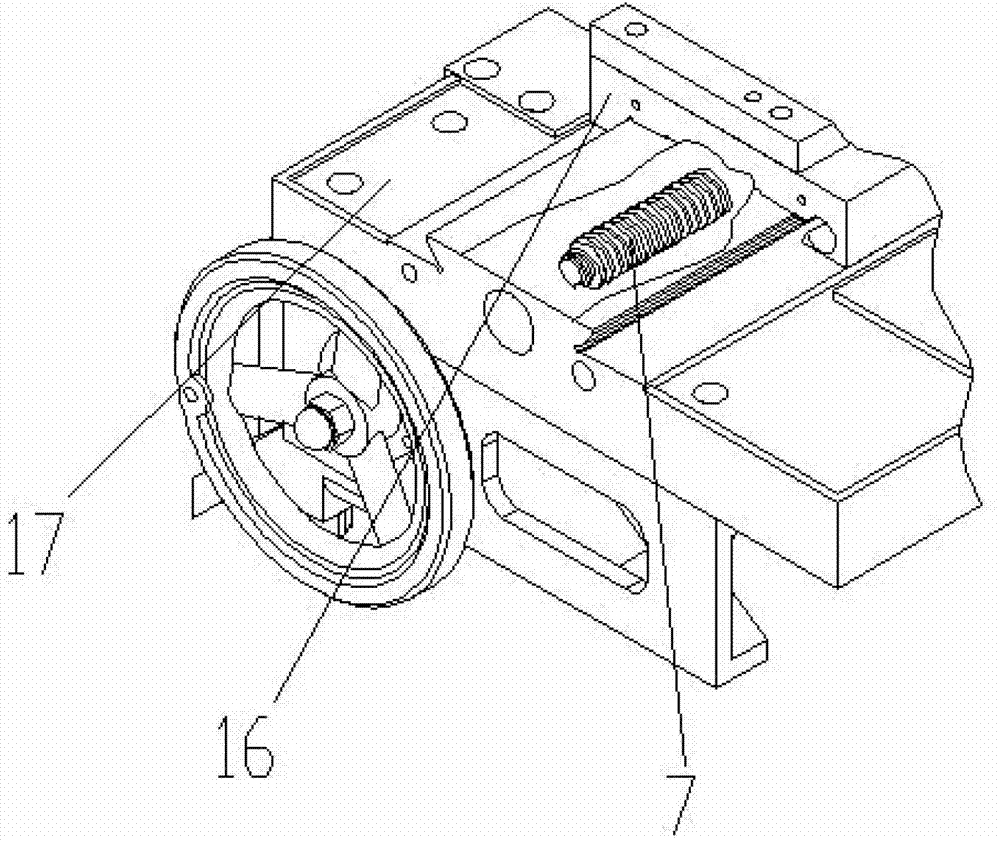

[0013] Examples such as Figures 1 to 2 As shown, a CNC lathe for worm gear processing includes a bed 1, a gear box 2 arranged on one end of the bed 1, a main shaft 5 is arranged inside the gear box 2, and a motor for detecting the rotational speed of the main shaft is installed on one side of the gear box 2. The main shaft encoder 3, the upper part of the gearbox 2 is provided with the numerical control system 4 connected with the main shaft encoder 3 circuit, the other side of the bed 1 is provided with a tailstock 12, and the top end 10 is installed on the tailstock 12, and one end is also installed In the taper hole of the main shaft 5, the other end of the worm gear hob 9 abutting against the top 10 is arranged on the first carriage 17 in the middle of the bed 1, and the first carriage 17 is provided with a first stepper motor 11 and a The work that the first carriage 17 cooperates enters the carriage 16, and the work advances the carriage 16 and the first stepping motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com