Method and device for cleaning nozzles of alignment film printer

A technology for cleaning devices and printers, which is applied in the directions of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc., which can solve the problem of prolonged production time, waste of production time, PI liquid, nozzle blockage, etc. problems, to achieve the effect of improving printing quality, reducing production costs, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

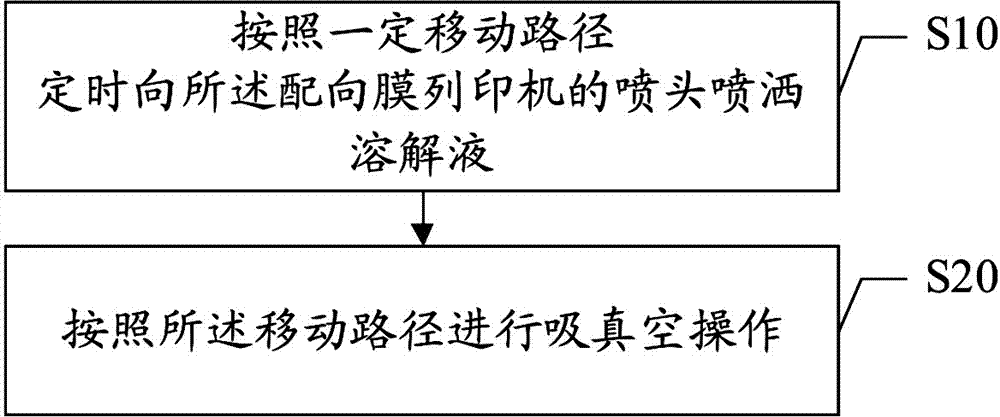

[0038] Such as figure 1 As shown, the method for cleaning the nozzle of the alignment film printing machine according to the embodiment of the present invention includes the following steps:

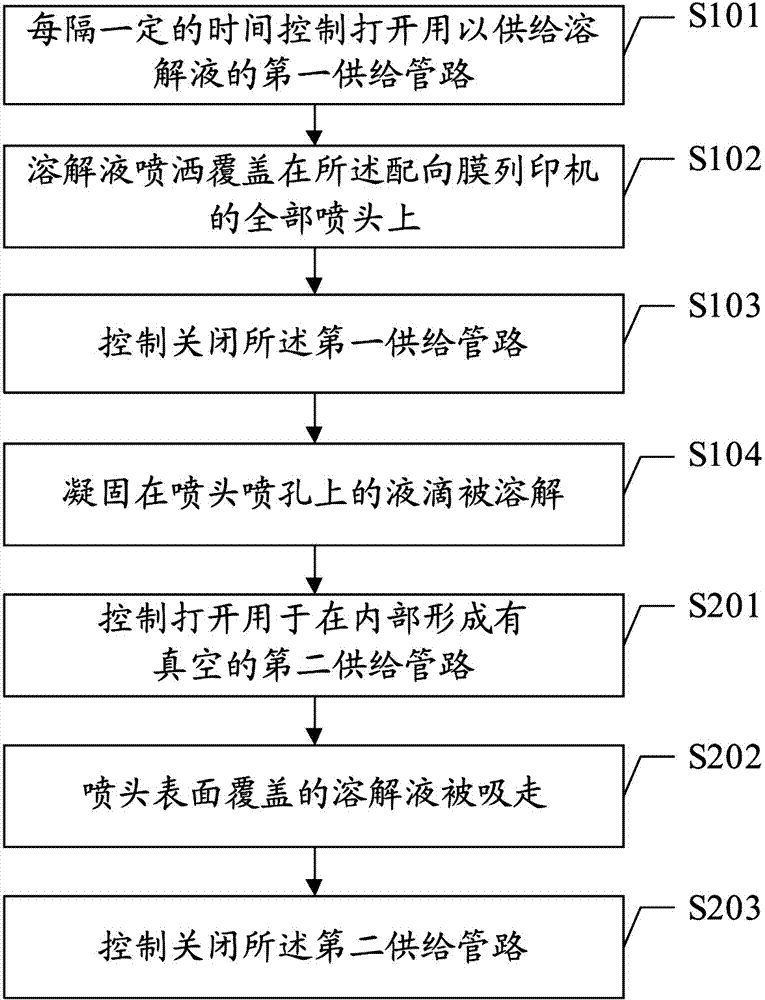

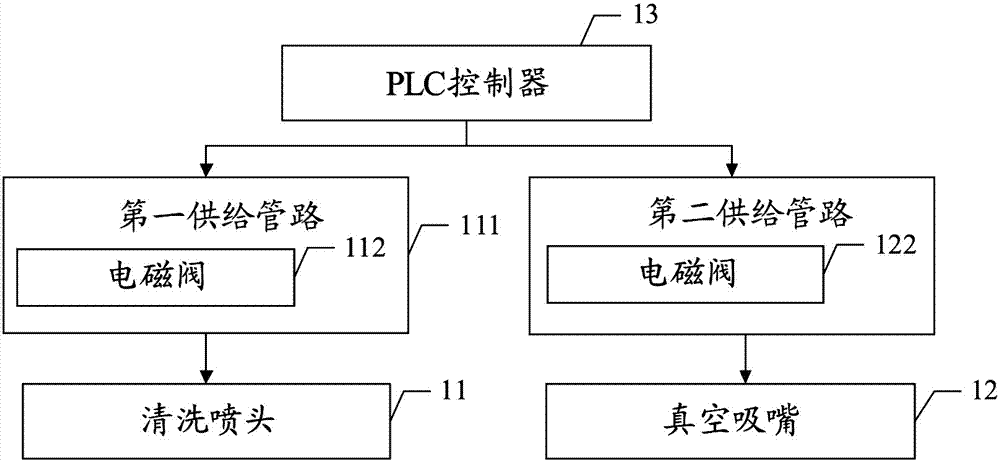

[0039] Step S10, regularly spraying the dissolving solution to the nozzle of the alignment film printer according to a certain moving path, to dissolve the liquid droplets solidified on the nozzle holes of the nozzle, and spray the solution to cover the alignment film printer on all nozzles.

[0040] Step S20, performing a vacuuming operation according to the moving path to suck away the solution covered on the surface of the spray head.

[0041] Among them, since the droplets ejected from the nozzle holes of the nozzle of the alignment film printer are PI liquid, and the PI liquid is easy to dry up or solidify and cause the nozzle holes to be blocked, the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com