Backpack type electric fertilizer applicator

A fertilizer applicator and knapsack-type technology, applied in the field of fertilizers, can solve the problems of complex fertilization mechanism, high cost, and great impact on human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

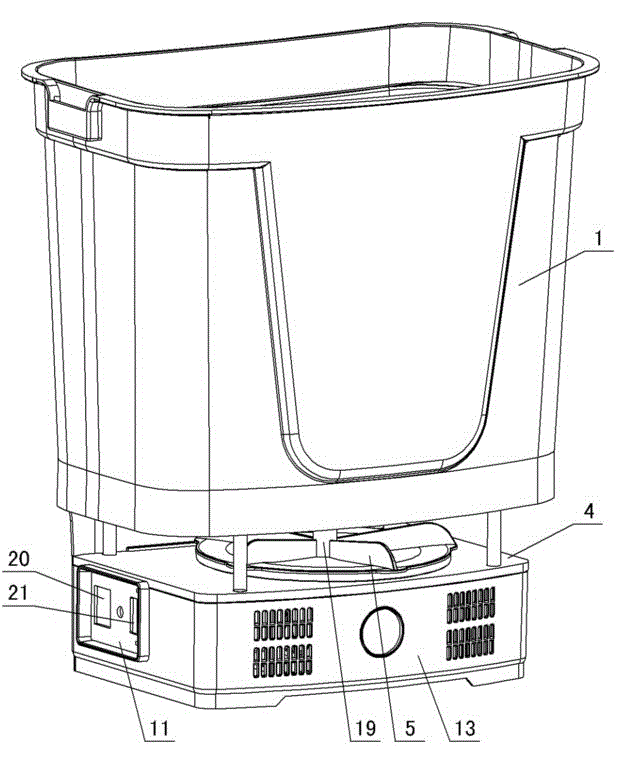

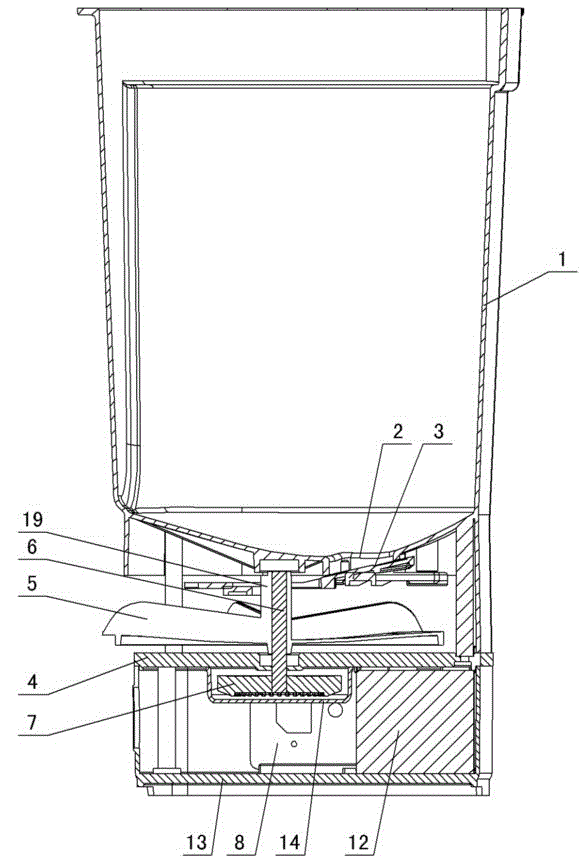

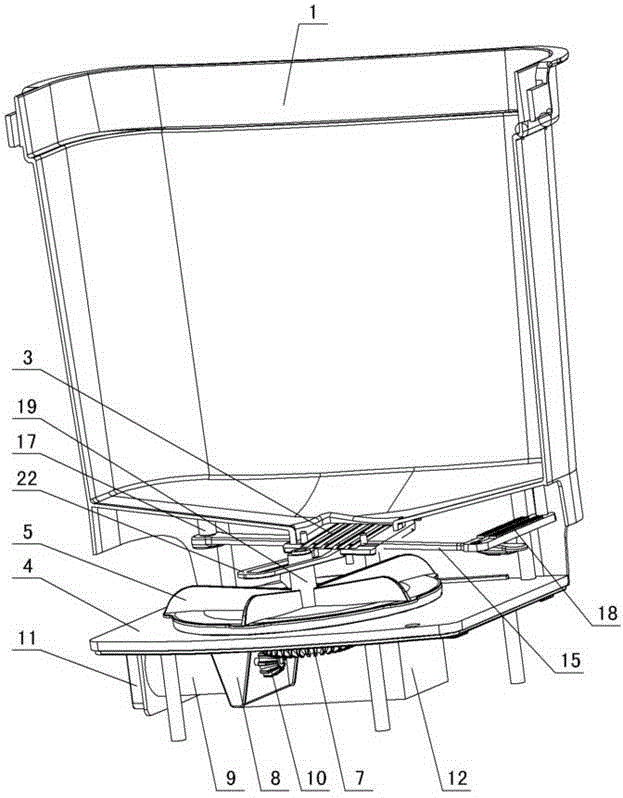

[0012] The present invention relates to a kind of knapsack type electric fertilizer, such as figure 1 — Figure 5 As shown, it includes a chemical fertilizer bucket 1, the bottom of the bucket is provided with a discharge port 2, and a sliding plate 3 is installed under the discharge port, and the sliding plate is matched with the discharge port 2. The bottom cover 13 is connected, the fan blade 5 is arranged on the base, the fan blade is formed with a shaft sleeve 19, and the shaft sleeve is installed with the shaft 6, the upper end of the shaft is rotated and matched with the lower bottom of the material barrel through the bearing, and the lower end of the shaft passes through the base 4 to connect to the helical gear plate 7. It is characterized in that: a motor fixing seat 8 and a panel 11 are formed under the base 4, a motor 9 is installed on one side of the motor fixing seat, the output shaft of the motor passes through the motor fixing seat 8 and is connected to a pinio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com