Method and system for on-line maintenance of storage battery

A battery and power line technology, applied in the field of power systems, can solve problems such as batteries that cannot be solved in real time, and achieve the effect of solving the problem of parameter exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] figure 1 For the flowchart of the battery online maintenance method disclosed in the embodiment of the present invention, refer to figure 1 As shown, the method may include:

[0044] Step 101 : The monitoring device performs on-line monitoring of the voltage, current and temperature of the battery, and performs check discharge, internal resistance test and on-line balance maintenance on the battery.

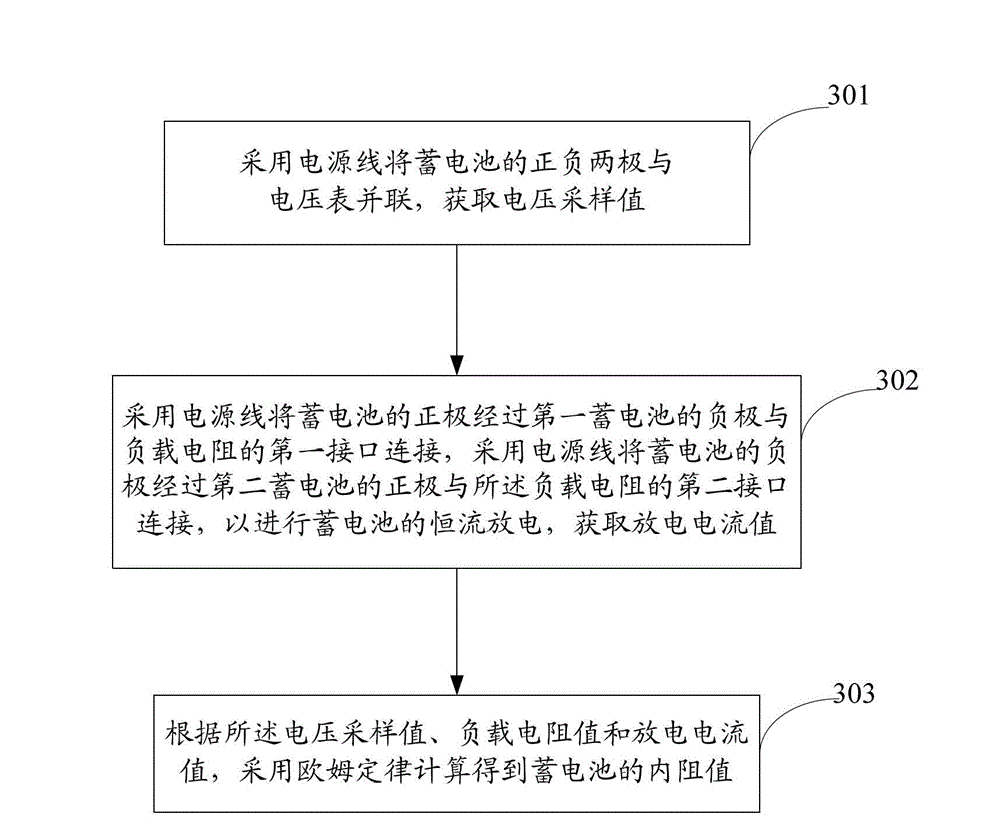

[0045] The specific wiring and operation process of the internal resistance test can be found in figure 2 and image 3 , figure 2 It is a schematic diagram of the circuit for measuring the internal resistance of the battery disclosed in the embodiment of the present invention, image 3 The flow chart of the method for measuring the internal resistance of a battery disclosed in the embodiment of the present invention is as follows: figure 2 and image 3 shown, can include:

[0046] Step 301: Connect the positive and negative poles of the battery in parallel with a...

Embodiment 2

[0065] Figure 5 It is a schematic structural diagram of the battery online maintenance system disclosed in the embodiment of the present invention, see Figure 5 As shown, the battery online maintenance system 50 may include:

[0066] The monitoring device 501 is used to monitor the voltage, current and temperature of the battery on-line, and perform check discharge, internal resistance test and online balance maintenance on the battery.

[0067] Wherein, the monitoring device may include an internal resistance testing device, which is used to connect the positive and negative poles of the battery in parallel with a voltmeter using a power cord to obtain a voltage sampling value; using a power cord to connect the positive pole of the battery through the negative pole of the first battery and the load resistance The first interface of the battery is connected to the first interface of the battery, and the negative electrode of the battery is connected to the second interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com