Three-dimensional profile measuring system of trinocular camera with two-dimensional laser profile scanning sensor

A two-dimensional laser and camera technology, applied in the field of optical inspection, to achieve the effect of expanding the effective measurement field of view, avoiding the reduction of edge measurement accuracy, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

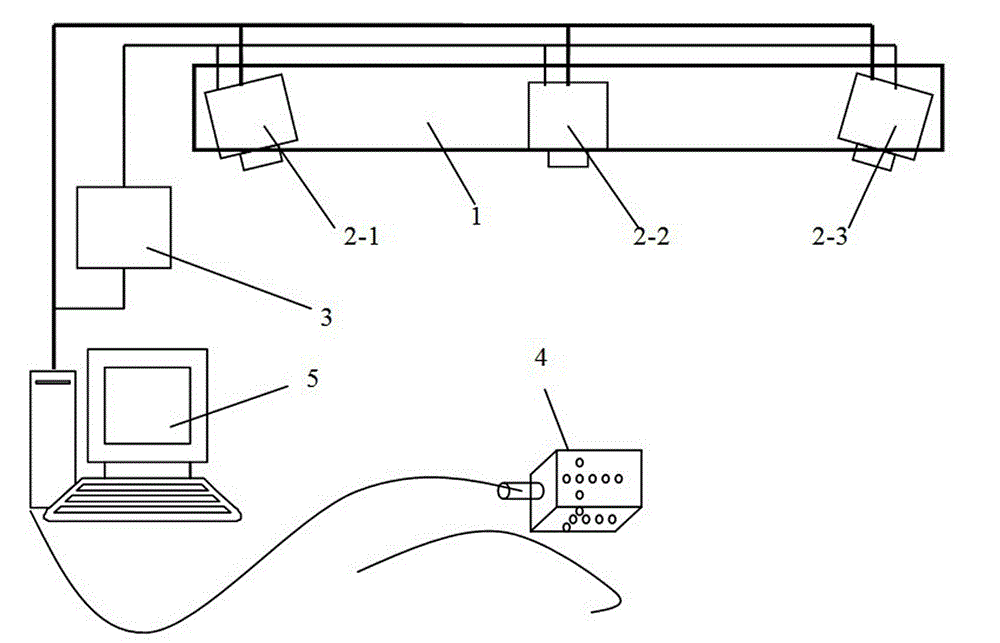

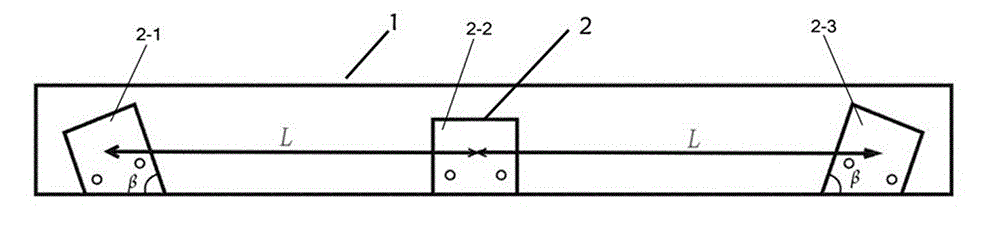

[0019] refer to figure 1 , 2 , the camera array is composed of three cameras, the first camera 2-1, the second camera 2-2, and the third camera 2-3 are placed in the camera card slots of the camera array base 1 respectively. The groove bottoms of the first video camera 2-1, the second video camera 2-2 and the third video camera 2-3 are on the same plane, and the center positions are on the same straight line. The center of the second video camera 2-2 The distance from the position to the center position of the first camera 2-1 and the third camera 2-3 400 mm, the axis of the second camera 2-2 is perpendicular to the length direction of the camera array base 1, and the angle between the axis of the second camera 2-2 and the length direction of the camera array base 1 Both are 70 degrees.

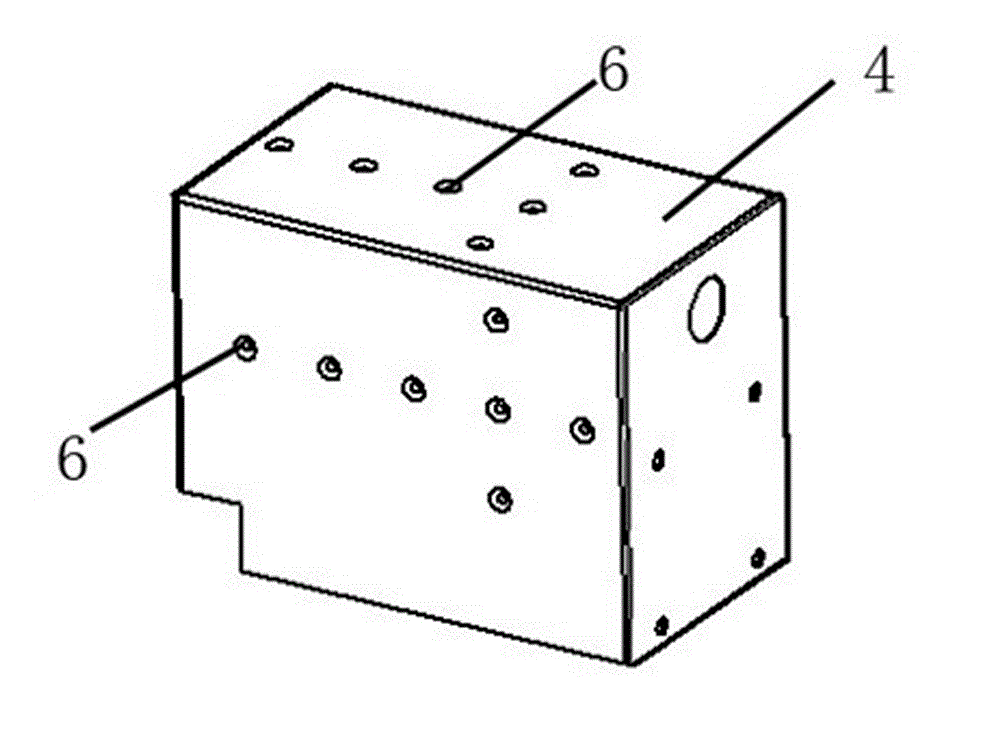

[0020] Such as image 3 , Figure 4 As shown, the hand-held laser profile scanner 4 is a cuboid, in which two faces are equipped with marking points 6, and the numbers of marking point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com