Two-axis photoelectric collimator based rotary table division error detection method

A photoelectric autocollimator and indexing error technology, which is applied to instruments, measuring devices, and optical devices, etc., can solve the problems of photoelectric autocollimator not leveling, inconvenient operation, and great influence on measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

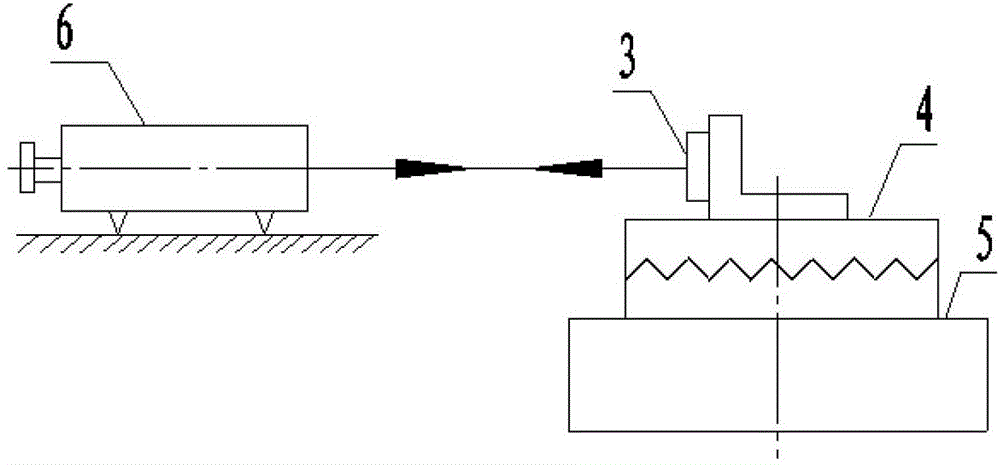

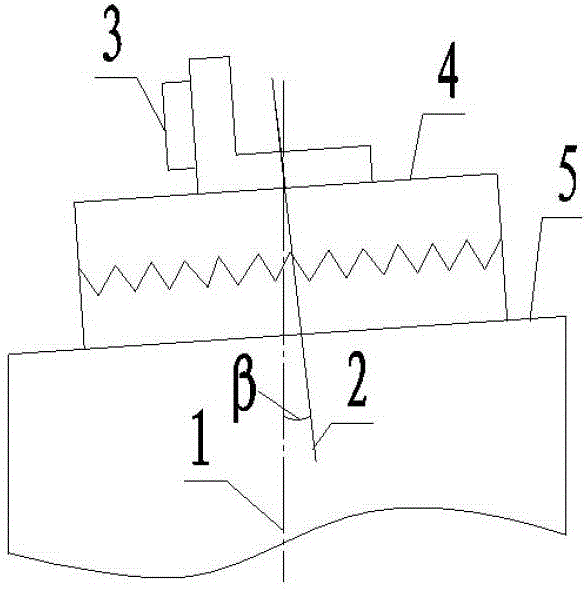

[0053] The multi-tooth indexing table is used as the indexing reference part, and its rotation angle is used as the standard angle. The actual rotation angle of the turntable is compared with the standard angle, and the angle deviation method is read by the high-precision dual-axis photoelectric autocollimator for the detected turntable. Take two measurements. The measurement method is: (1) Install the multi-tooth indexing table at the center of the working surface of the inspected turntable, fix the plane mirror on the multi-tooth indexing table, and use the autocollimator to aim at the plane mirror;

[0054] (2) Rotate the inspected turntable once so that both axes of the dual-axis photoelectric autocollimator have readings;

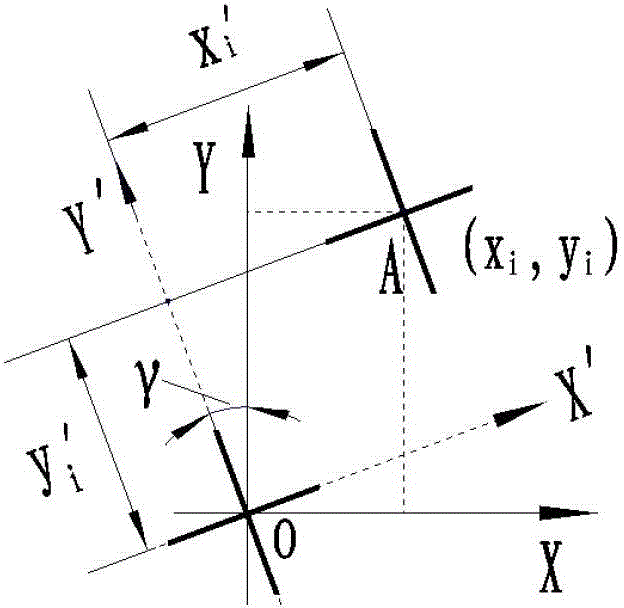

[0055] (3) Set the checked turntable to the zero position, read the initial value of the biaxial photoelectric autocollimator, and then rotate the multi-tooth indexing table and the reflector together with the checked turntable by an angle of φ, said φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com