Automatic deashing device for thermal-powered or thermoelectric boilers

An automatic ash cleaning and boiler technology, which is used in the removal of solid residues, lighting and heating equipment, combustion products treatment, etc. Overall coordination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

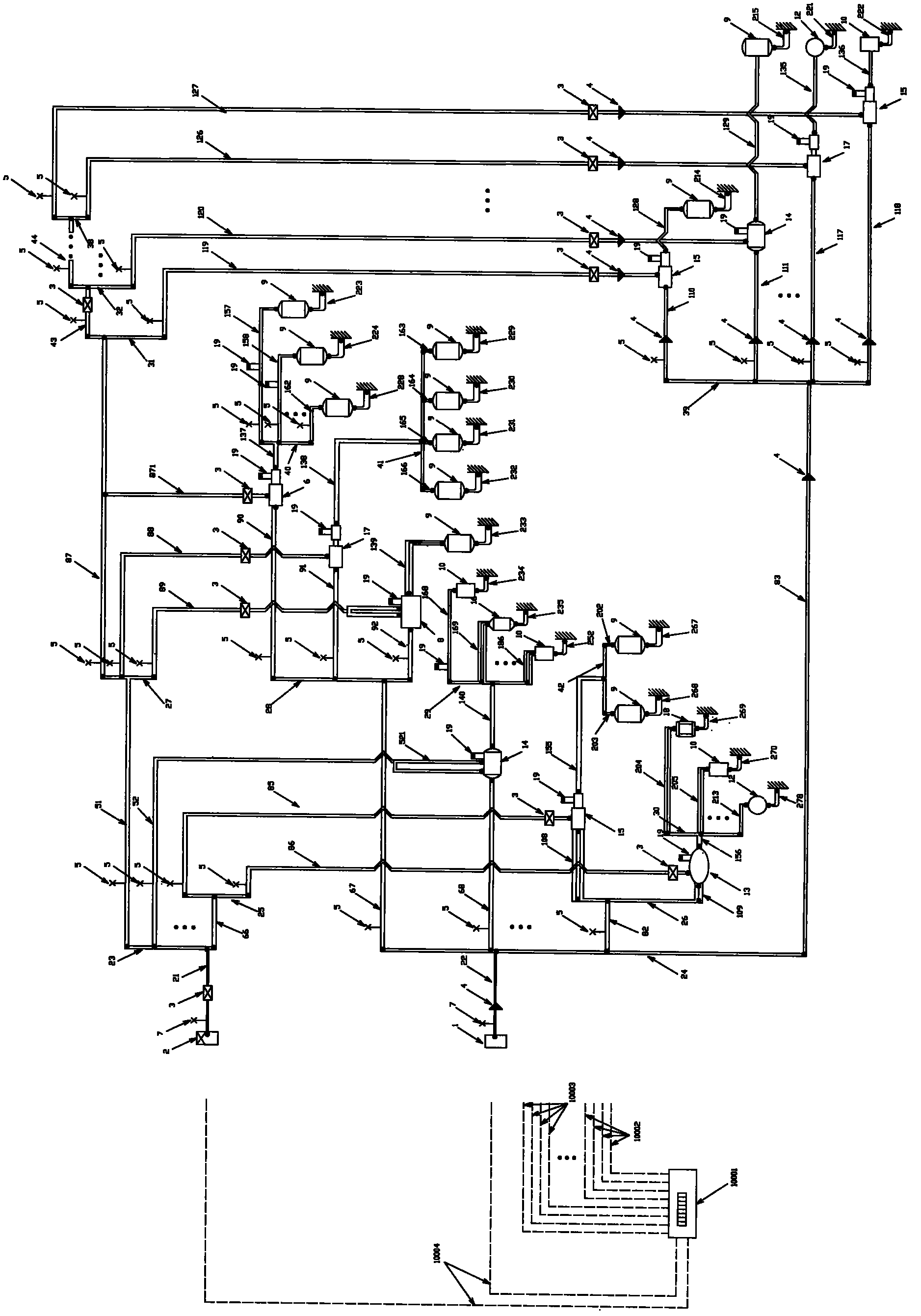

[0030] The system of the present invention consists of a gas source, a main branch converter, an energy starter, an energy temporary storage container, a diversion tube, a blocking component, a connecting pipeline, a control valve, a PLC and a control valve, a control cable, etc. figure 1 connected.

[0031] Such as figure 1As shown, the gas source 2 uses bottled acetylene gas at a certain pressure, and is connected to the main pipeline 21. The steel pipe whose outer diameter ranges from 8mm to 180mm and whose wall thickness ranges from 0.8mm to 45mm is selected, and the main control valve 7 is set. Connect a fire arresting valve 3 according to the conventional fire arresting requirements, and the main pipe 21 is connected to the inlet of the gas collector 23 for the main sub-conversion distribution. The gas collector 23 adopts a square metal tube with a side length of 300mm to 900mm, and the two ends are sealed and welded to form a container 16 holes are opened on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com