Magneto-rheological damper

A magneto-rheological shock absorber and magnetic core technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of leakage at coils and wire leads, inconvenient maintenance and inspection, and viscous damping force Low-level problems, to achieve the effect of good sealing, compact structure, and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

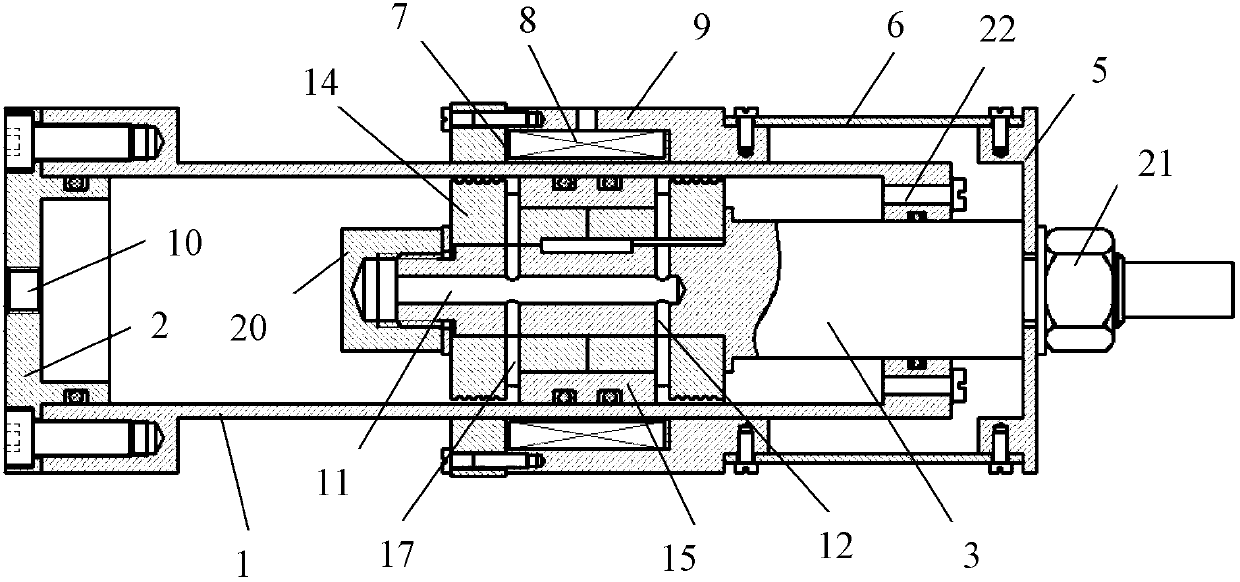

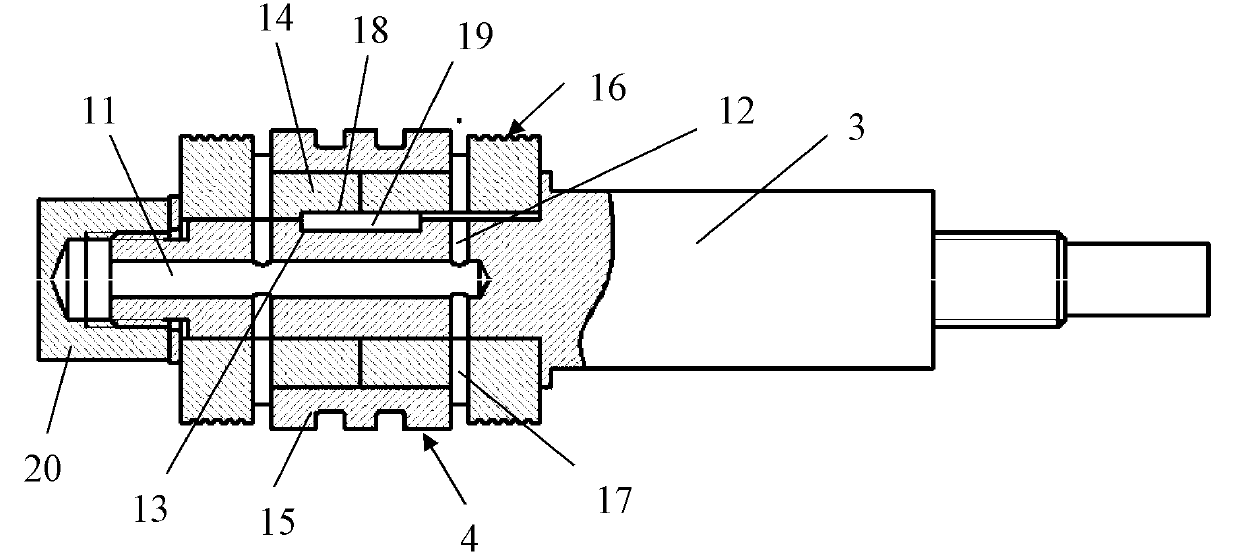

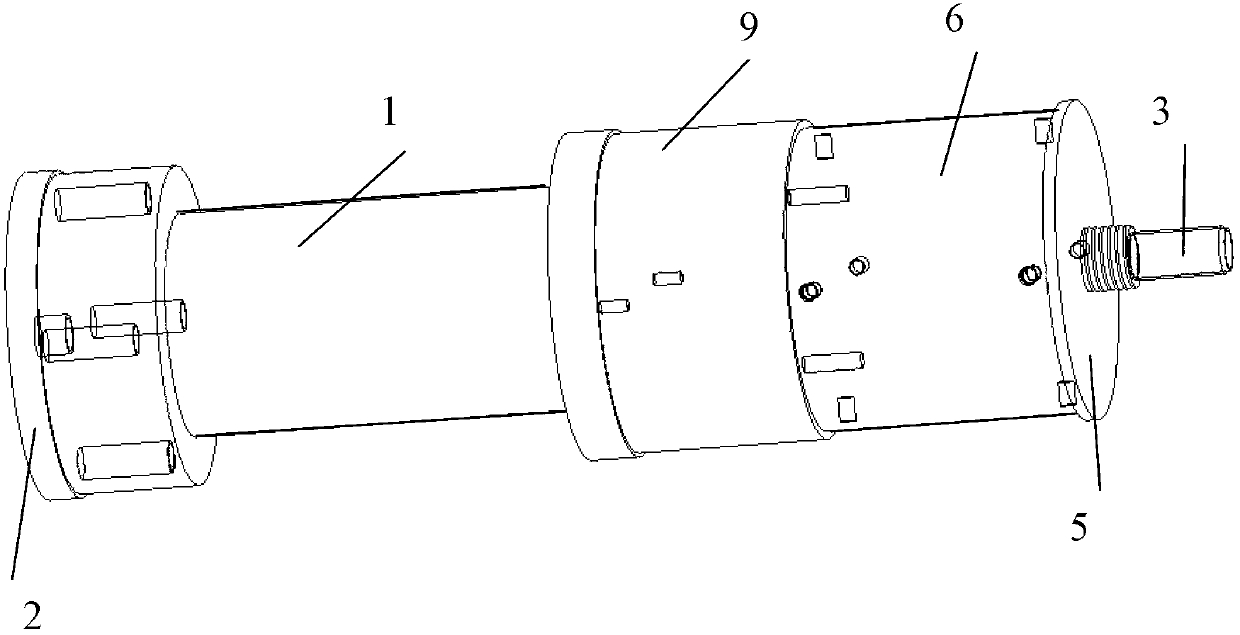

[0018] The magneto-rheological shock absorber provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0019] Such as Figure 1-Figure 4 As shown, the magneto-rheological shock absorber provided by the present invention includes a cylinder 1, a left end cover 2, a piston rod 3, a piston 4, a right end cover 5, a connecting cylinder 6, a bobbin 7, a coil 8, an external magnetic conductor 9 and Cover mother 20; wherein the cylinder 1 is in the shape of a tube, and the inside is filled with magnetorheological fluid and filled with high-pressure nitrogen; the left end cover 2 is fixed on the left end of the cylinder 1, and a charging valve connection hole 10 is formed in the center; the piston An axial central hole 11 is formed inside the left end of the rod 3, threads are formed on the outer surface of the left end, and two rings of piston rod radial holes 12 are formed at a distance from each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com