Common-rail pipe of gas engine

A gas engine and common rail tube technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problem of increasing the difficulty factor of common rail tubes, and achieve the effects of low manufacturing cost, smooth gas flow, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the structure and function of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

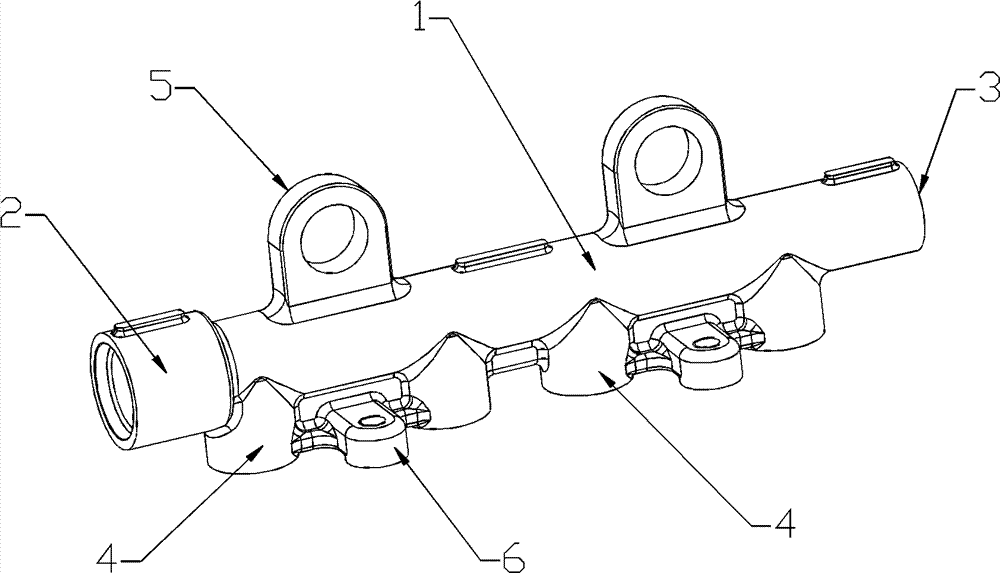

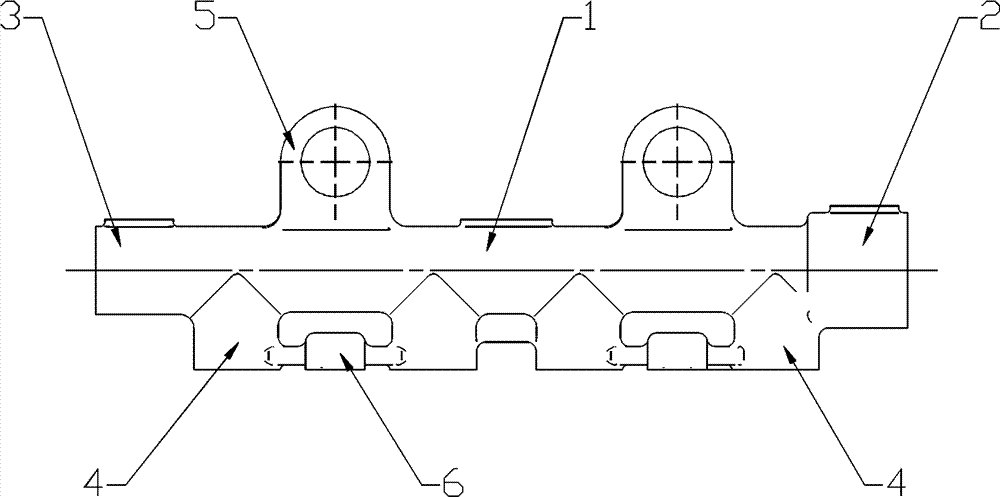

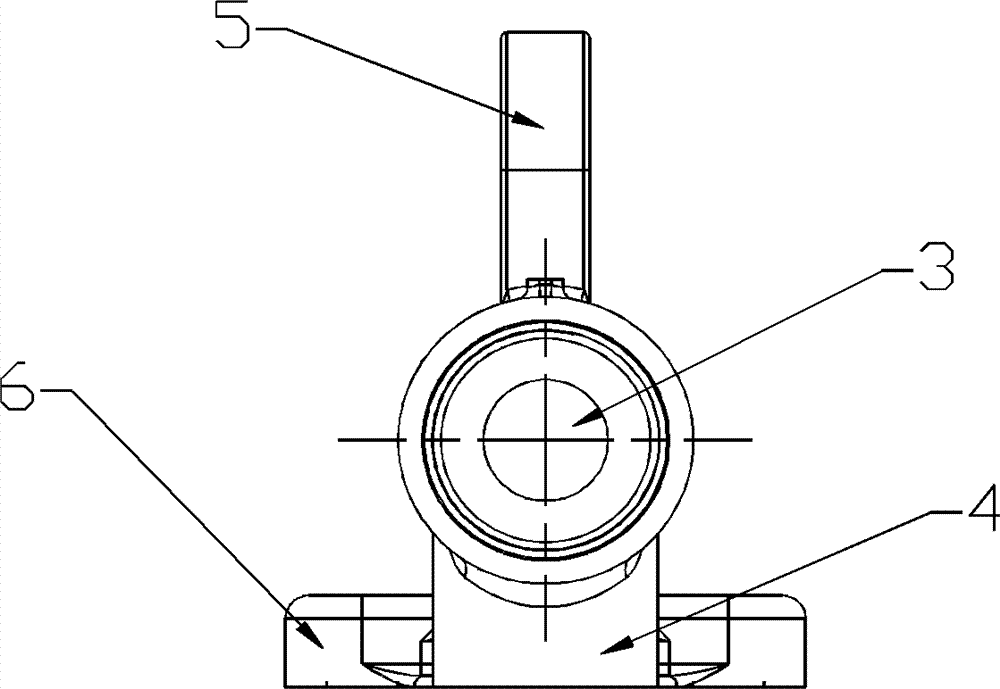

[0023] Figure 1 to Figure 4 They are schematic diagrams of the external structure of the gas engine common rail pipe of the present invention, including a perspective view, a front view, a left view and a bottom view. As shown in the figure, the common rail pipe of the present invention only needs to include a round tubular Gas main pipe 1 and four gas manifolds 4, one end of the gas main pipe 1 is a sensor installation port 3 for installing sensors, and the other end is a gas inlet and outlet 2, these four gas manifolds 4 are arranged on the gas main pipe 1 to form A straight line and perpendicular to the gas main pipe 1, on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com