Mobile support bracket of tunneling machine

A technology for roadheaders and roadways, which is applied to mine roof supports, mining equipment, and earth-moving drilling and mining, etc., can solve the problems of roof easily hurting people, slow driving speed, and unsafe working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

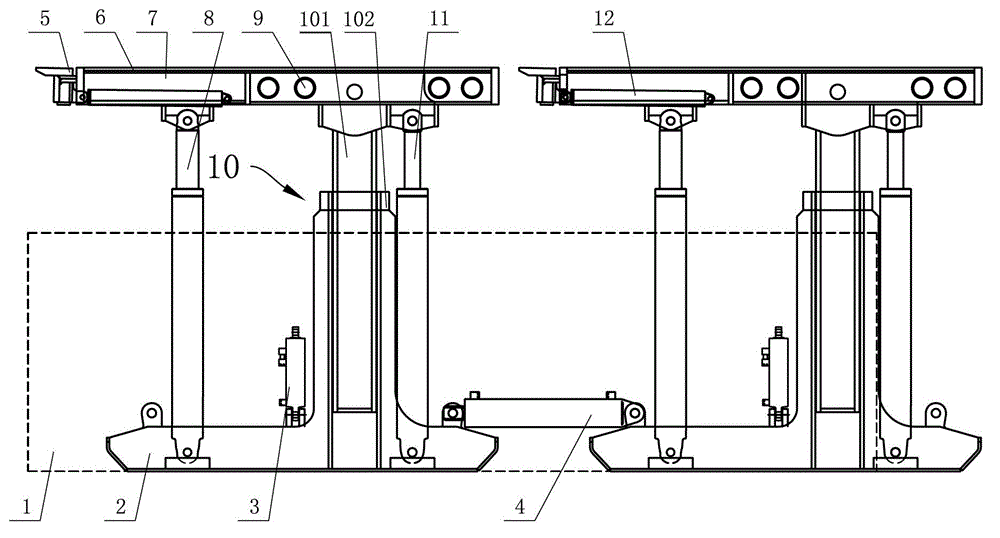

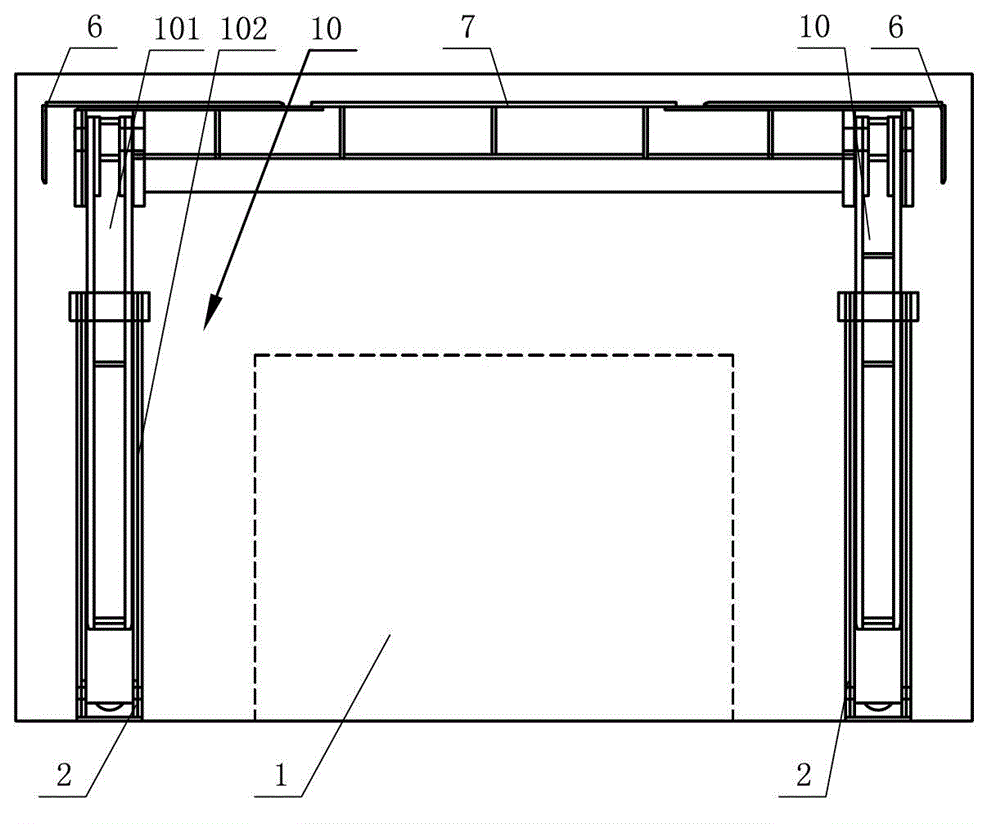

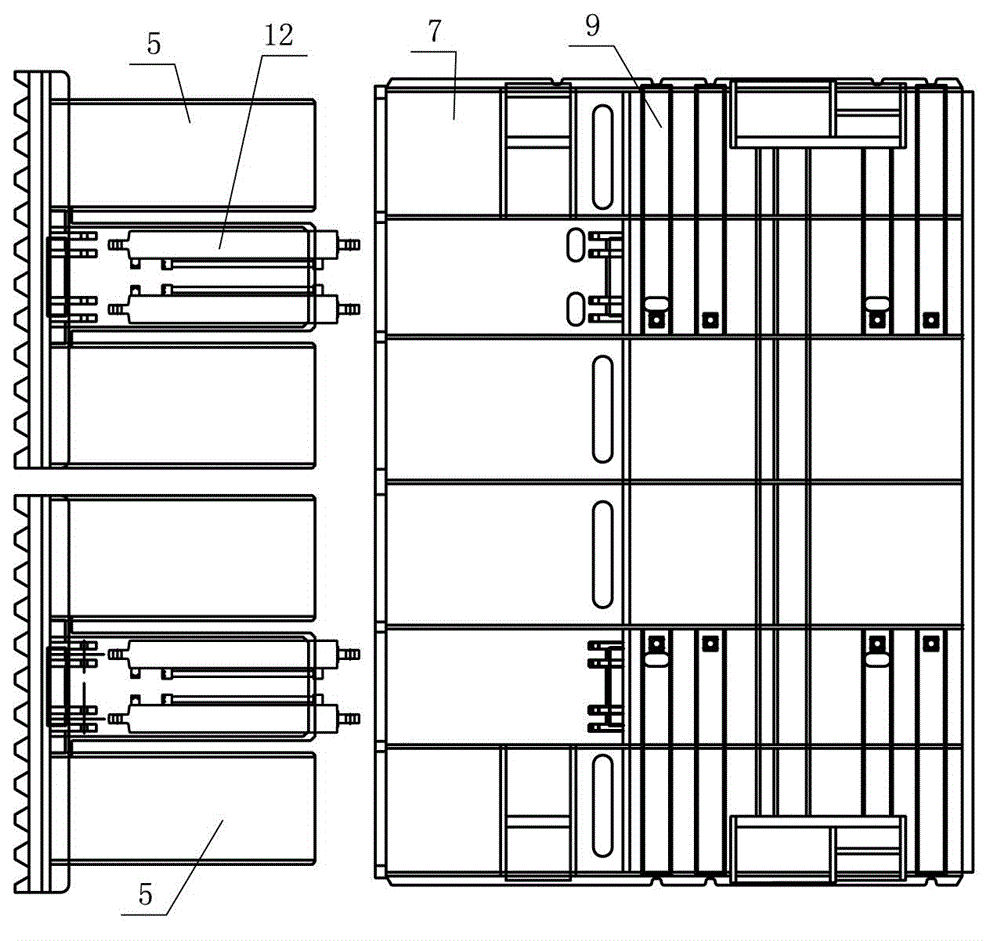

[0017] Such as figure 1 , figure 2 and image 3 Commonly shown, a roadway boring machine mobile support bracket, including two bracket units arranged side by side, each bracket unit includes a base 2 on both sides of the roadheader 1 and a top beam 7 above the roadheader 1 A lifting mechanism supporting the top beam 7 is connected between the base 2 and the top beam 7, and the lifting mechanism includes a front column 8 connecting the base 2 and the top beam 7, a rear column 11 and a lifting device 10, and the lifting device 10 is located between the front column 8 and the rear column 11, so that the space can be fully utilized, and the force on the top beam 7 can be balanced. The front column 8 and the rear column 11 are commonly used in the field through hydraulic pressure Control the lifting column, the lifting device 10 includes a lifting seat 102 arranged on the base 2, the lifting seat 102 is inserted with a slide bar 101, the slide bar 101 is hinged on the top beam 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com