Template type underwater dry-type well head structure

A dry, base plate technology, applied in wellbore/well components, sealing/isolation, earthwork drilling and production, etc., can solve the problems of high production cost, complex structure, difficult to achieve yield in marginal oil fields, etc., to reduce Production cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

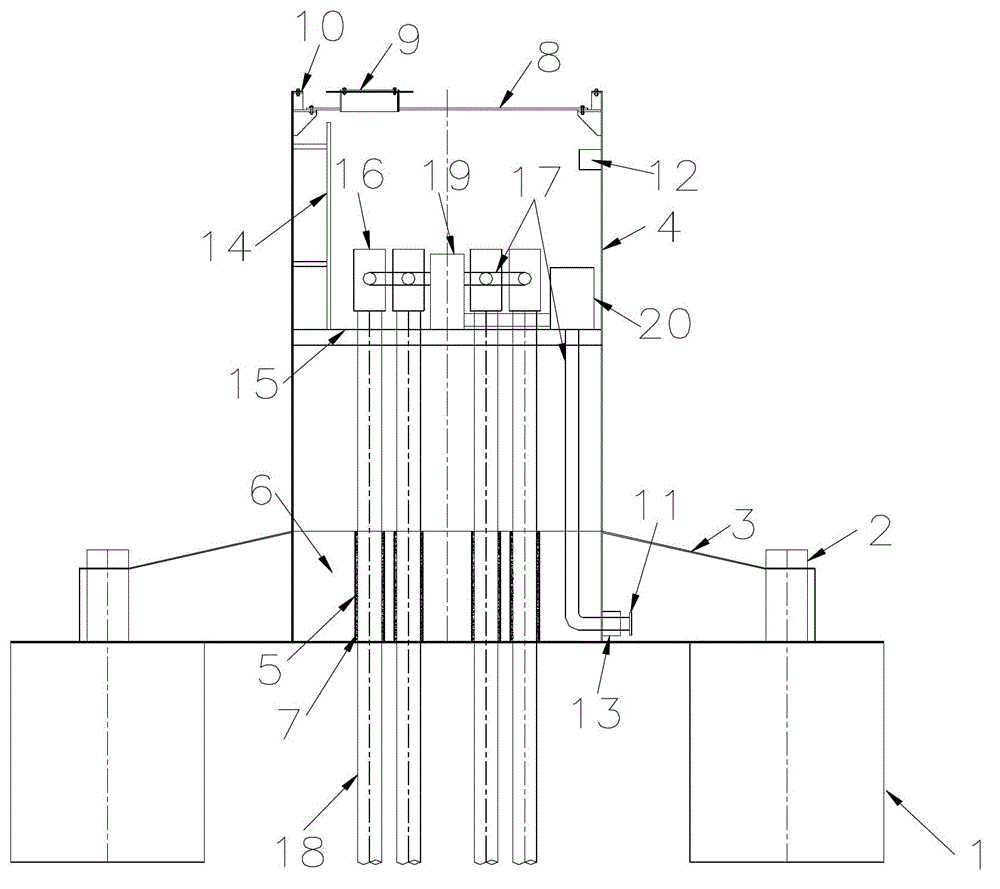

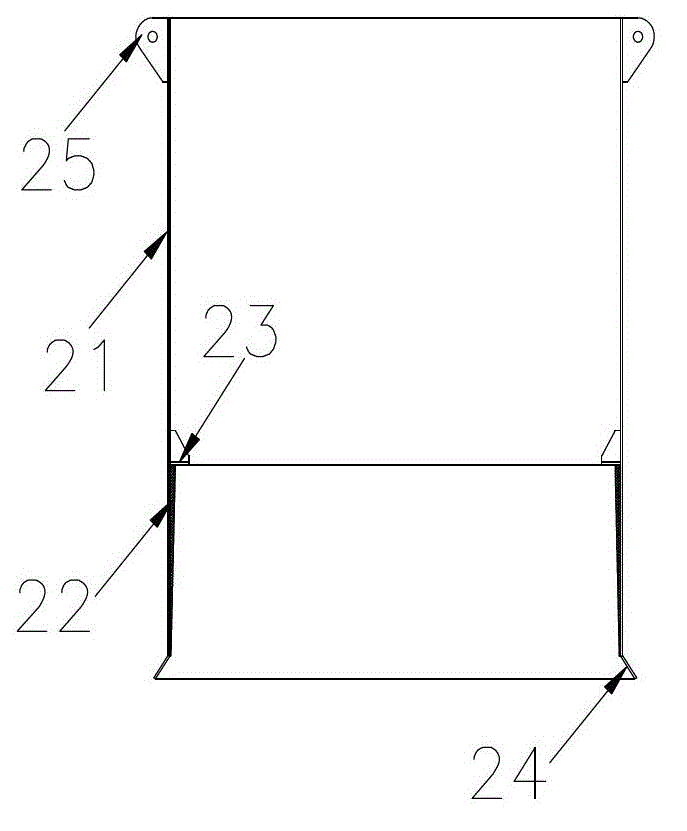

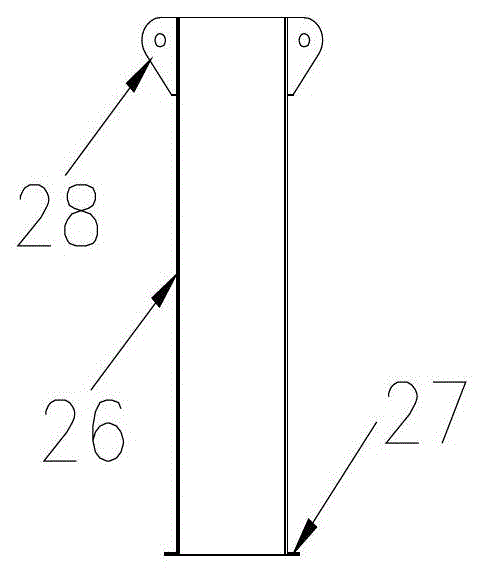

[0028] Such as Figure 1-3 As shown, the present invention is provided with a base plate, a dry cabin installed on the base plate, and a wellhead, wherein the base plate serves as the foundation of the underwater dry wellhead structure and provides bearing capacity for it. The base plate includes: several cylindrical foundations 1, a column 2 installed in the inner center of the cylindrical foundation 1, and several connecting beams 3 installed on the upper part of the column 2, the upper ends of the connecting beams 3 are connected with the dry cabin, and the cabin of the dry cabin The body 4 is provided with a water-resistant sleeve guide 5, and the water-resistant sleeve is installed on the dry cabin through the water-resistant sleeve guide 5. There are three or four cylindrical foundations 1, columns 2 and connecting beams 3 in this embodiment. The cylindrical foundation 1 is a large-diameter short pile with a cover on the top; when installing, the cylindrical foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com