Workshop safety line marking tape and its construction method

A technology of sign tape and safety line, applied in road signs, roads, traffic signals, etc., can solve the problems of fast aging of polyester materials, increase production costs of enterprises, insufficient product adhesion, etc., to reduce dust dead ends, low cost, Easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

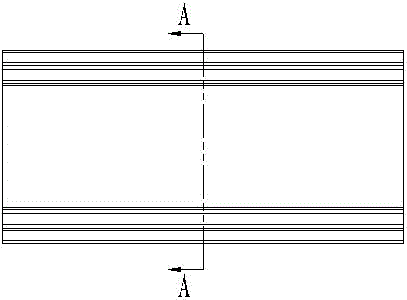

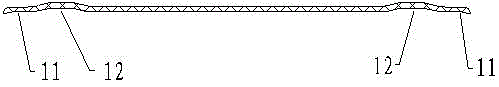

[0027] refer to Figure 1-3 As shown, a workshop safety line marking tape 1 has a strip structure as a whole and is molded by plastic at one time. Its cross section is in the shape of an upper chord arc. A circular arc with a larger radius of curvature than a straight line. The marking tape is pasted on the ground and is used to divide the workshop area into safety passages and transportation passages. The cross-section is upper chord arc shape, which is easy to fit the ground and realizes zero-gap fit with the ground.

[0028] like figure 2 As shown, the left and right sides of the cross section of the marking tape 1 are provided with a fixing groove 11 and a glue groove 12 sequentially from outside to inside. The glue-holding structure of the glue tank 12 is groove-shaped, which firmly fixes the marking tape on the ground, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com