Online induction heating and shallow hardening process after outer thread processing of pipe end

An induction heating and external thread technology, which is applied to the field of on-line induction heating shallow hardening process after the pipe end external thread processing, can solve the problems of high hardening cost, inappropriate hardening thickness, and proportion imbalance, so as to avoid the problem of non-concentricity and ensure Hardening effect, reliable action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

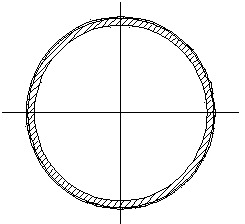

[0037] Section wall thickness: 3mm

[0038] Section hardened layer thickness: minimum 0.47mm, maximum 0.52mm

[0039] Induction coil moving speed: 103.2cm / min

[0040] Workpiece (pipe) speed: 80r / min

[0041] Hardness of hardened layer: the hardness of six slices are HRC51, HRC52, HRC51, HRC52, HRC53, HRC51

[0042] Based on the above data: the maximum hardness of the hardened layer is HRC53, and the minimum value is HRC51, which meets the requirements above HRC45, and the hardened layer is relatively uniform

[0043] Hardened layer thickness: 0.47 / 3=0.156=15.6%

[0044] 0.52 / 3=0.173=17.3%

[0045] Hardened layer thickness difference: 0.52-0.47=0.04mm

[0046] The thickness of the hardened layer is more than 20% of the wall thickness, and the thickness of the hardened layer is relatively uniform, which meets the hardening requirements.

Embodiment 2

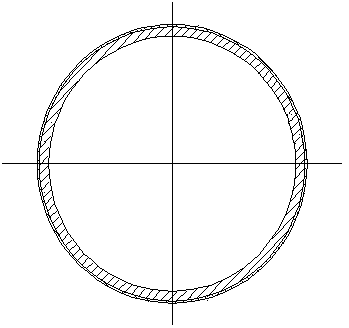

[0048] Section wall thickness: 3mm

[0049] Section hardened layer thickness: minimum 0.49mm, maximum 0.53mm

[0050] Induction coil moving speed: 120.3cm / min

[0051] Workpiece (pipe) speed: 85r / min

[0052] Hardness of hardened layer: the hardness of six slices are HRC49, HRC51, HRC51, HRC50, HRC50, HRC49

[0053] Based on the above data: the maximum hardness of the hardened layer is HRC51, and the minimum value is HRC49, which meets the requirements above HRC45, and the hardened layer is relatively uniform.

[0054] Hardened layer thickness: 0.49 / 3=0.163=16.3%

[0055] 0.53 / 3=0.176=17.6%

[0056] Hardened layer thickness difference: 0.53-0.49=0.04

[0057] The thickness of the hardened layer does not exceed 20% of the wall thickness, and the thickness of the hardened layer is relatively uniform, which meets the hardening requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com